If before construction we initially simply decide on the building material that suits us in terms of price and quality, then when this choice is made, we will have to additionally think about what kind of selected material should be purchased. If housing will be built from foam concrete, then you need to know which foam blocks to choose for a house - one or two-story, or for interior walls, what to look for, what to fear.

What to look for when choosing

Foam blocks allow you to quickly and inexpensively build a one or two-story house that holds heat well, is light and comfortable for exterior and interior decoration.

In order to understand which foam blocks are better for building walls of a house, first of all, one should pay attention to such an indicator as density. The greater the density level, the more severe the foam block will be and the greater its thermal conductivity. Weight affects the choice of the foundation for the house, and the heat transfer - the need for additional insulation. This should be considered at the design stage of the house.

Note! Foam concrete only becomes harder with time. Studies show that foam blocks that have stood in laying for 50 years are 3 times harder than fresh foam blocks.

Density

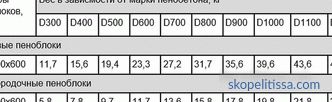

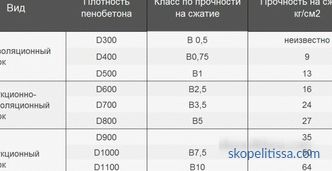

Density can be determined by the numbers after the letter "D" in the marking, which can be in the range from 100 to 1200 units (indicate how many kilograms the material withstands per unit area):

-

From 100 to 300 units - exclusively for the construction of internal partitions in the house. Foam blocks with a density of 100-200 units are used very rarely.

-

From 400 to 500 - suitable only for thermal insulation, such foam blocks contain up to 70% of air, respectively, the size of the bubbles (pores) is significant, low load bearing capacity, high heat retention rates (low thermal conductivity). Of these blocks, you can build a second contour of the walls, which are not bearing.

-

From 600 to 1000 is used for mounting external walls. The most common option. Of these blocks, you can safely lay the bearing walls of a one or two-story house. Thermal conductivity indices are somewhat worse, however, higher strength for load bearing. Most often used for external walls foam blocks with a density of 900 units.

-

Density 1100 - 1200 is suitable for a three-story house. Above the house of foam blocks do not build.

On our site you can familiarize yourself with the most popular foam block houses from construction companies represented at the Low-Rise Country home exhibition.

Dimensions and hardness

For external walls, the usual dimensions are 20 * 30 * 60 cm, for internal partitions 10 * 30 * 60 cm. These are the optimal values, however, other foam concrete blocks are available that differ up or down - from which you can build any architectural form.

Another indicator of the quality of a foam block is its hardness.

Denoted by the letter "B". Shows compressive strength. That is, what kind of load in kilograms per centimeter will withstand.

-

From 0.5 to 1 unit . Characteristic of the blocks intended for the construction of internal walls, the heat-insulating contour of the house

-

2.5 to 7.5 . Suitable for the construction of exterior walls with good thermal insulation properties, low thermal conductivity. Can be used for the walls of the first and second floor.

-

10 to 12.5 . The hardest foam blocks that are used for load-bearing walls. If you choose which foam block is better for building a two-story house, then this is the only correct answer. If the house is built with a reasonable economy, then from such blocks you can build the first floor, and leave less durable for the second.

Quality of foam blocks

There are several ways to check the quality of foam blocks, as they say, "by eye". You can estimate the following parameters:

-

Structure uniformity . Bubbles should be about the same, not connected to each other. It is possible to break one block into the sample, everything will be visible at the cut;

-

Cell sizes . The larger the pores, the more air in them, the better it keeps the heat and the better the sound insulation. And the less hardness;

-

Color . Very indicative check. The block should be concrete color, uniform over the entire surface.A lighter color means that the foam block is of poor quality;

-

Weight and geometry . To choose a foam block and weigh, on average should weigh 22 kg. Blocks must be the same size. It costs to put one on another, the difference will immediately be visible, if there is one.

Tip! You can check the quality by trying to break off a piece of foam block with your hand. If it turned out to be done, then the material is of poor quality. If you managed to press a nail with your hands, then such a block should not be bought either.

It might be interesting! In the article on the following link read about the projects of brick houses.

What else to look at when choosing foam blocks

-

Cost . If the price is significantly lower than the market, has no economic justification, it means that low-quality components of raw materials are used. Price reduction can be, if the manufacturer is close, and offers free shipping - this can be, if a sufficient amount of purchases. In other cases, most likely, taking too cheap building material is not worth it.

-

Foam concrete strength increases with time . In the process, shrinkage occurs. It takes 1-2 months for shrinkage, which is 2-4 mm per linear meter. Shrinkage occurs evenly, does not affect the quality. But in no case can you use freshly made blocks for building. They need 3-4 weeks for complete drying and the necessary strength to start laying. Therefore, be sure to check when the foam blocks were made.

-

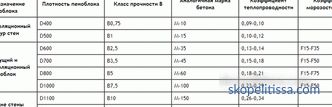

There is one more indicator of the quality of foam blocks - frost resistance . It shows the resistance of the foam blocks, the preservation of the structure during repeated freezing - defrosting. This cyclicality allows you to choose foam blocks for any climate zone. Frost resistance is measured in cycles. It can be from 15 to 75 units. For the southern regions, the frost resistance index is from 15 to 30. For the central regions, it is better to choose the indicator from 30 to 50. For the northern regions, respectively, from 50 to 75.

-

The lack of foam concrete associated with 17> mounting complexity , can be ignored using special dowels and anchors designed for mounting in porous surfaces.

-

Reduced are used for fixing to the foam block density and heterogeneous structure . To be sure that the manufacturing process does not violate the proportions and quality of mixing, you need to purchase material from large manufacturers with guarantees and documentation confirming the quality and composition.

It might be interesting! In the article on the following link read about the projects of aerated concrete houses.

Summing up

-

If you chose a foam block as a building material for a house, then before selecting and erecting the foundation, you need to decide with dimensions and weight foam blocks for exterior and interior walls. The larger the size and the higher the density, the heavier the blocks and the higher their cost. Accordingly, a more powerful and expensive foundation is required.

-

Foam blocks with a density of not less than 600 units are suitable for exterior walls. The most common material is with a density of 900.

-

For internal walls and partitions, materials with a density of 100-300 are used. Usually these are blocks with dimensions of 10 * 30 * 60 cm.

-

Blocks with a density of less than 600 are used only for heating at home. How to carry them can not be.

-

Plays a role and cold resistance . It is necessary to take into account the climatic features of the place of life when buying blocks. The house should be warm and comfortable in any weather and temperature.

-

Check quality foam concrete , its color, structure. Request a certificate of quality from the seller, where the results of the study in the laboratory.

-

Buy from large sellers building materials. Reputation is very important for them and it’s almost impossible to “run into” counterfeit. If there are only small manufacturers nearby, then all the nuances should be checked especially carefully.

-

Price also plays a role in the selection. Too high price and too low should scare away. Too low indicates low quality components, or cheap technology. Poorly mixed foam will break the bubble structure, the pores will be interconnected, which means the hardness of the material will be broken, and the absorption of moisture will increase.

About the control purchase of foam blocks, see the video:

On our website you can find contacts of construction companies that offer service of construction of houses from turnkey foam concrete.Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Conclusion

Foam blocks - this material is quite simple to make, than artisan workshops actively use. Unfortunately, choosing which foam blocks are better for building a house, their properties, such as frost resistance and heat capacity, cannot be determined "by eye" - this requires expertise in the laboratory. Therefore, an attempt to save on the purchase of building materials from non-certified manufacturers may lead to the fact that the built house will not meet the necessary requirements.

Rate this article, we tried for you