There are several ways to exterior finish the house of aerated concrete - which one is better depends on the task. If we are talking about a simple version, then it is painting. A little harder and prettier - finishing with decorative plaster. And hinged facades are a separate category for which they produce a whole "family" of materials and finished systems. In the latter case, in addition to the cladding, it is possible to improve the insulation of the facade, although this is not necessary for aerated concrete walls. And the most difficult and time-consuming way - brick lining. And now about the merits and features of each option.

Features of aerated concrete that need to be considered

For gas silicate concrete blocks open cellular structure. It has its positive and negative sides.

Dignity - the breathable properties of the walls. Vapor permeability of aerated concrete is higher than that of wood across the fibers. A natural gas exchange with the street creates a favorable microclimate in the house, even without arranging an expensive system of forced ventilation. But the same property imposes restrictions on the use of certain materials. For example, such walls can not be insulated using polystyrene foam or EPPS - conditions of moisture transfer are violated, and the walls during the heating period will begin to soak.

An open cellular structure is characterized by hygroscopicity - aerated concrete easily absorbs moisture when it comes in direct contact with precipitation. For example, water absorption of aerated concrete can reach 20%, and even for an ordinary brick, this indicator is 1. 5-2 times lower. It is considered that the gas-block should be protected in order not to worsen the heat-insulating properties and to keep the design parameters of frost resistance. And this is especially necessary when the same block from two sides are affected by different temperatures, and the dew point is in the middle of the porous material.

At the same time, there are studies that prove that the depth of the layer active changes in temperature and humidity are in the range of 5-30 mm. That is, even under extreme weather conditions, the outer layer, the thickness of which does not exceed 10% of the total, will itself act as protection for the deep layers. But still it is better to protect this layer. Moreover, with perfect geometry and flatness, the appearance of the aerated concrete block can hardly be called attractive. Based on all these nuances, we understand that you still need an exterior finish of the house of aerated concrete, which is better to be considered in each case.

Important! Despite the high compressive strength, aerated concrete material is brittle and its surface can be easily damaged.

Staining

For the most part, gas silicate blocks are laid on glue. The thickness of the horizontal seam does not exceed 3 mm. The vertical seam can be even less if the blocks have a “thorn-groove” profile, and their connection in a row occurs without the aid of glue. This is good for thermal insulation, but not in a decorative sense - even ordinary brickwork with joint work looks better. Just take and paint the wall is also impossible - the seams will appear even through two layers of paint.

There are two ways of painting the facade of aerated concrete blocks:

-

Traditional - on plaster . Apply a special thin layer plaster for aerated concrete. Sand surface to perfectly smooth, primer and paint.

-

Direct staining . For this method, it is necessary that the walls should be lined with chamfered blocks, or the chamfer at the blocks be removed before laying. This technique creates the illusion of masonry walls made of large wall stones with joint joints, and this is a classic of construction. The process of painting itself follows the traditional pattern: applying a primer, and after it dries - two layers of paint.

Important! For this method of finishing the facade of the house, it is better to choose silicone paints from aerated concrete blocks. They have a high vapor permeability combined with hydrophobic properties - natural gas exchange and moisture transfer will not be disturbed, and rain will roll without penetrating into the block structure.

looks like. On our site you can familiarize yourself with the most popular projects of aerated concrete houses from construction companies represented at the exhibition "Low-Rise Country".

Decorative plaster

High vapor permeability of a gas silicate requires a certain sequence of wall decoration. Before exterior finish of the house of aerated concrete it is necessary to finish the finishing work from the inside. When the inner plaster dries out, water vapor evaporates outward, passing through the walls, which means it can moisten the facade plaster.In addition, before the beginning of the facade works, the wall should “stand up” and acquire a stable humidity regime - adapt to the operating conditions. This is due to the fact that the intrinsic moisture content of the gas silicate block, from which it is allowed to sell it, can be equal to 30%, and the optimum moisture content for finishing is about 15%.

Decorative plaster is applied in two layers. And the sequence of works looks like this:

-

The surface of the wall is grounded .

-

a base reinforcing layer of plaster is applied with a notched trowel. The thickness of the layer in the ridge - 6-8 mm.

-

Superimposed reinforcing glass mesh resistant to alkaline media. It is pressed into the base layer with a metallic trowel, while simultaneously smoothing and leveling the layer. As a result, the thickness of the "base" should be no more than 4-5 mm.

-

Give the base layer dry . Under normal conditions, the number of days to the finish is equal to the base thickness in millimeters.

-

“Paint” the surface with primer .

-

a finishing layer of decorative plaster is applied.

-

The need for painting depends on the type of plaster. Dry white mixtures are colored, ready-made compounds are tinted in bulk.

Important! When using ready-made blends, be careful of the batch number. As with conventional paint, shades of mass-colored plaster from different batches can be visually different.

How to plaster the facade of a house of gas silicate blocks can be seen in the following video:

On our website you can find contacts of construction companies that offer the service insulation and decoration of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

A hinged facade

A hinged facade for exterior decoration of a gas concrete house is not necessary to be installed together with insulation. With a width of 375-400 mm block with a density of D500-D600, the thermal insulation properties of the facade comply with modern standards for thermal protection of buildings in the regions of central Russia. Especially when you consider that the interior also has certain thermal insulation properties.

If it was decided to install the hinged facade together with insulation (for example, with a block width of 300 mm), then it is necessary to finish all the internal work related to the use of mortars - to make screeds, apply plaster, put tiles. Aerated concrete blocks and mineral wool (in particular, it is used in the insulation of aerated concrete walls), “absorb” moisture, which must then be weathered. And if the work takes place in the fall, then the heating season can be met with a facade that has lost some of its thermal insulation properties.

Both the insulation and the supporting subsystem of the ventilated facade must be securely fastened to the porous block.

And although the strength and retention capacity of fasteners for aerated concrete is higher than foam concrete, the choice of anchors or dowels must take into account the characteristics of the base material and the weight of the facing panels. For example, vinyl siding is lighter than fiber cement, and a weight of 1 m 2 block depends on its thickness. Therefore, the type of fasteners in each case is individual.

Tip! It is better to choose a ready ventilated facade system, which the manufacturer adapts to the architecture and building materials of the house

Otherwise, the standard technology:

-

Spend pegging of the carrier subsystem.

-

Attached through heat-insulating gaskets brackets for the cladding .

-

Fixed to the wall insulation mats .

-

The superdiffusion waterproofing membrane is placed.

-

Mount front panels.

Selecting the type of facade panels very large:

-

Six types of siding : wooden, vinyl, wood-polymer composite (WPC), fiber cement, steel, aluminum.

-

Five types of wooden slatted panels : front wall paneling, imitation of timber, block house, plank, deck (decking) board.

-

Large-format porcelain stoneware .

-

Aluminum composite panels.

-

Front fiber cement panels for natural stone and brickwork.

This may be interesting! In the article on the following link read about the vulture home trim.

Features of brick cladding

Technically, such finishing of a house of aerated concrete in essence boils down to the construction around the perimeter of the building of another wall in a half-brick. And so that the weight of the cladding can withstand the foundation, it is necessary to take it into account at the design stage of construction or reconstruction of the house.

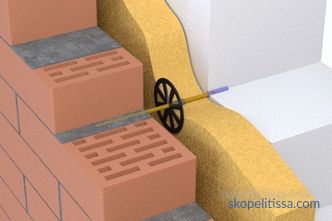

Another feature is the difference in vapor permeability. Even with a slit facing brick, it is significantly lower than that of autoclaved aerated concrete. Even more difference between the clinker and hyperpressed bricks. Therefore, regardless of whether the insulation is carried out with mineral wool or not, the ventilated gap between the main wall and the lining must be.

A characteristic of a half-brick laying is that it does not have sufficiently high strength for mechanical stress. In order for such a wall to stand well, it must be literally “tied” to the main wall.

When laying building blocks on cement-sand mortar, you can use different types of ties - reinforced mesh, wire, nails, metal strips and flexible ties embedded in the seams of both walls.

Important! You can lay ties in the main wall in horizontal and vertical joints, in cladding - only in horizontal ones.

In order not to impair the thermal insulation properties of the walls, it is desirable not to use metal bonds. In this case, only two types remain:

-

masonry mesh made of alkali-resistant fiberglass;

-

flexible connections from basalt plastic or fiberglass.

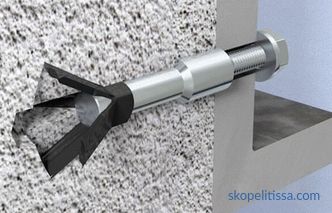

Only flexible connections are suitable for aerated concrete blocks laid on glue mortar. The masonry has no vertical seams, and the horizontal seams of the large-format block and the facing brick do not coincide with each other in level. Therefore, in order to “tie” the lining, holes are drilled in the main wall for connections.

General requirements :

-

by 1 m 2 4 connections are needed;

-

near openings and corners the number of links is doubled;

-

for ventilation, every third or fourth vertical seam of brickwork at the bottom row and under the eaves is left empty, and if the house is with a gable or several floors, this procedure is repeated every three meters in height.

The brick technology is described in the video below:

It might be interesting! In the article on the following link, read about the siding of a wooden house.

Conclusion

It is unambiguous to say which exterior decoration of a gas concrete house is impossible. In each case, there is a preference for the owner of the house, and still need to take into account the architectural features of the building. Everything is individual - for someone in the first place is the originality of the exterior design of the house, and the other is important to meet the construction budget. For example, in the decorative relation fibrotsementny panels under a brick are not inferior to the original, but cost cheaper (especially taking into account work). And the price of wood panels depends on the type of wood, the country of the manufacturer and the type of factory processing. But in any case, finishing is necessary, and its properties should take into account the characteristics of aerated concrete.