The article contains information about the built-up roof - its price, installation cost. Details are described varieties of this material, the characteristics that you need to pay attention to when choosing.

What is build-up roll roofing

Build-up roof is a type of soft roll bituminous waterproofing intended for covering operated and unexploited flat roofs or with a slight slope by fusing a gas burner flame.

Material composition:

-

The upper protective layer is a film or a coarse-grained dressing, most often of slate crumb. The layer is needed to protect the roof from ultraviolet radiation and other harmful factors.

-

The upper layer of the binder , consisting of a mixture of bitumen with polymers.

-

Dense base .

-

The bottom layer of the bitumen-polymer binder.

-

Lower protective layer made of easy-to-melt polymer film. It is needed so that the material in the roll does not stick together during transport. The film is heated during installation by the flame of the burner, some of the bitumen flows out and, while frozen, glues the coating to the roof surface.

You can buy a build-up roof in rolls with a width of 1 m and a length of 10, 15 or 20 m. The thickness of the material ranges from 2.8 to 4.6 mm. A coating with an upper protective layer of film costs a little less than a similar material with coarse-grained dressing. On the front surface of the roof with dressing on one side there should be a sprinkled edge 85 - 100 mm wide (to create overlap strips during installation).

When buying, pay attention to the fact that the cheaper type of roofing coatings are for sale in rolls are pasting. They are glued to the surface of the roof or fixed with nails.

Characteristics

The cost of the deposited roof, its quality depends on the following characteristics:

-

Flexibility temperature on a bar . By this parameter, it is possible to judge the material's resistance to cold - the smaller the specified radius and the lower the temperature - the higher the elasticity of the coating. When the temperature is below zero, bitumen materials become brittle; cracks may appear on the finished coating or in a roll during installation. A good indicator is flexibility on a bar R = 25 mm at -25 ° C. It means that the laying of this brand of roll roofing can be done at temperatures up to -25 ° C. Material with a temperature of flexibility on a 25 mm 0 ° C timber can be bent without risk of cracking only in the warm season.

-

Heat resistance . This characteristic is expressed by the limiting value of positive temperature, which the roof endures without loss of properties. For bitumen roll materials, this figure should be at least 70 ° C.

-

Tensile strength . This parameter is expressed by the force (H) that must be applied to break the strip of material. The minimum value for the weld roof according to the requirements of the standard is 274 N.

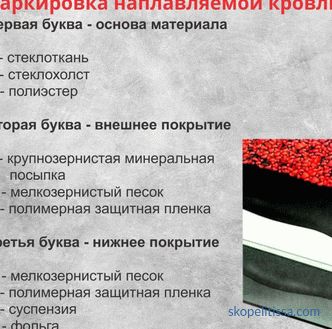

Marking

The marking of a roll overlaid roof consists of three letters, sometimes after them put numbers, meaning a weight of 1m² of material in kg. For example: EKP 3.0 - square. m weighs 3 kg. Decoding of letter marking:

-

first letter - base material Р, Э, Х, Т;

-

second letter - top layer type , film (P) or coarse-grained topping (K);

-

the third letter is the type of the bottom layer (thick plastic film, P).

On our site you can familiarize yourself with the most popular sites in the Moscow region for the construction of a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Types and prices

The characteristics of roofing waterproofing in rolls depend on the type of foundation. Overlaying roof, types and prices of the material depending on the basis:

-

Roofing cardboard (marking starts with the letter P) - Rubemast RNA and RNP. Roofing paperboard is a material made from plant fibers and differs from the usual one by its high absorbency. Tensile strength of 294 N, service life up to 15 years. Rubemasta price of cardboard - RNP from 60 rubles / m², RNA from 65 rubles / m².

-

Fiberglass (X). Tensile strength - 300 N. The disadvantage is inelasticity. In the process of installation or changing the size of the roof, which occurs under the influence of temperature drops, the roof of this type may break. Service life up to 15 years. Approximate prices - HSP from 55 rubles / m², HKP from 80 rubles / m².

-

Fiberglass (T). Tensile strength - from 400 to 900 N. The minus is the same as that of fiberglass roofing - inelasticity, but due to high strength it does not tear, but exfoliates.Service life up to 20 years. Approximate prices - Chamber of Commerce and Industry from 65 rubles / m², TKP from 95 rubles / m².

-

Polyester (polyester fibers, E). The tensile strength of this type of roof is relatively low - from 300 to 600 N, but it is elastic, therefore it is the most durable and expensive. Especially recommended for new buildings where deformations are possible due to shrinkage. Service life up to 30 years.

Most Sellers indicate the price for a roll of a build-up roof. The calculation is easy to make, since most often the unit area of this material is 10 m² (15 and 20 m² are found, but rarely).

Features of assembly and disassembly

Basic rules for installation of roll fusing roofs:

-

Laying of roll covering starts with preparing the base - devices roofing pie. It usually consists of screed, vapor barrier, heat insulation.

-

If the roof is flat, then form a slope of not less than 1.5% and install the funnels of internal drainage.

-

It is necessary to have temperature joints - to prevent damage to the roofing carpet as a result of deformation of the base from temperature drops.

-

Vertical surfaces of the roof, made of brick or blocks, are necessarily plastered with a cement-sand mortar of grade not lower than M150.

-

Before installation, check the flatness of the base with the rail. Gaps should not exceed 5 mm along and 10 mm across the slope.

-

Gaps, irregularities are also sealed with cement-sand mortar M150.

-

The roof surface, which will be covered by the weldable roof, must be cleaned and treated with a bitumen primer (primer) - otherwise it is impossible to achieve strong adhesion of materials.

It might be interesting! In the article on the following link read about roof installation on the balcony: types of designs and prices + examples in the photo .

-

In places where rolled material will go on vertical surfaces, there should be inclined sides (they are also treated with a primer). The sides, drainage funnels, skates and endovy are covered with strips cut from a roll of bitumen roofing. Temperature seams are closed with the same strips, but by sprinkling down.

-

If the roof slope is more than 15%, then rolls roll strictly along the slope . If the slope is less - along and across.

-

To save material, prevent strip shifting, ideal flatness , pre-mark .

-

Laying start from down sections .

-

The film on the underside of the roll is melted by a roofing burner . With proper heating, the width of the layer of leaked binder up to 25 mm. More than 30 mm spilled - a sign of overheating, this is a guarantee of deterioration of the characteristics of the finished coating.

-

Walking on an unheated roof is strictly prohibited .

-

If the roof covering is made in 2 - 3 layers, then the joints of the strips should not match .

Approximate cost of installation work roll bituminous waterproofing (in rubles / m²): 1 layer - 170, 2 layers - 320. Installation of a drainage funnel from 1000 rubles / pcs. It is possible to buy equipment for a built-up roof from coatings manufacturers (for example, TechnoNIKOL), but it is better to entrust installation to experienced roofers.

For repair or restoration of the appearance of a soft bitumen coating, roofing slate is used in combination with mastic. These materials patch local damages or completely cover the old roof in places of overheating. The approximate cost of repair (excluding the cost of repairing the screed) is from 330 rubles / m². The most difficult option is with the dismantling of the old carpet, partial repair of the screed and laying a new coating in 2 layers - from 1250 rubles / m² (excluding materials).

Dismantling of the deposited roof costs about 85 rub / m² (excluding the removal of the screed and thermal insulation).

In the video you can see the installation of the weld Roofs:

It can be interesting! In the article on the following link read about the highlight of the landscape is the floating staircase and garden paths under which grass can grow.

Conclusion

The built-up roll roofing is an affordable option for designing and waterproofing the roof of a building, garage, industrial or industrial building.Provided the material is selected correctly and technology is installed, the bitumen coating in rolls will provide reliable protection of the building against precipitation and wind for a long time.

Rate this article, we tried for you