To be successful in today's market, building material from wood must have many virtues. In private housing construction materials that demonstrate durability, heat efficiency, environmental friendliness are valued. The popularity of the product largely influences the popularity of the product, which largely determines the final cost of a country house.

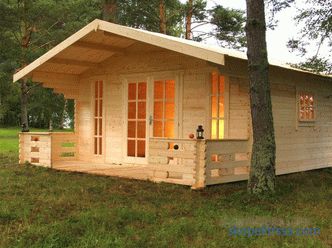

Thinking about building their own home, demanding owners are increasingly turning their eyes to a house from a mini-bar. This technology appeared on the Scandinavian Peninsula a few decades ago; in Russia, such buildings began to spread about ten years ago and immediately received high marks, both from builders and owners.

Mini-bar: scope

Mini-bar, being a relatively new material , became a successful competitor to solid timber (surpassing it in operational parameters) and glued profiled timber (as a cheaper alternative). Structurally, it is a copy of the standard construction timber, second only to the dimensions. The scope of the mini-timber covers all areas of suburban low-rise construction; The material can be used for:

-

Construction of temporary buildings (summer and guest houses).

-

Construction of capital houses for seasonal living .

-

Construction of suburban year-round homes in most climatic zones of the European part of Russia.

-

Home remodeling (extensions of the veranda, terrace or shed).

-

Landscaping of the garden plot (construction of a bathhouse and gazebos).

Species

According to the method wall constructions use a mini-beam of three configurations:

-

Unary . It is used for the construction of a seasonal holiday house, gazebo, children's house and a summer terrace.

-

Double . Suitable for the construction of a warm veranda and outbuildings. Double timber - the most common option for the construction of a capital country house.

-

Triple . Rarely used for regions with particularly harsh climates.

The thickness of the wall construction (beams-insulation-beams) depends on several parameters:

-

Features of the project . Will the house be used periodically or the family will live in it permanently.

-

From the method of heating housing.

-

From the geographical position and climate.

-

From the budget allocated for construction.

Walls are a structure of two or three parallel bars with insulation between them. Manufacturers offer a mini-bar with a thickness of 44 to 75 mm. The length of the product varies from 2 to 6 m. The width of the wall of a double or triple mini-bar is determined by the thickness of the insulation laid in the pier (100-150 mm). A common option is the double walls 44x100x44.

Technology: nuances and stages of manufacturing

Mini Timber (the second name is a tongue-and-groove board) is reasonably considered to be a progressive building material that meets the following characteristics:

-

Form . Plank (board) of solid wood with a profile and a thermal lock (cut-out, allowing to assemble the structure into a classic over-cut).

-

Material . Mini-bar is a natural material; made from softwood, pine and cedar.

-

Principle . The idea of the application is to achieve energy efficiency of the building while saving sawn timber.

-

Usage . For the construction of housing most often used double timber, forming a wall with the castle system.

Mini-bar: manufacturing stages

The technology of building a house from a mini-bar of chamber drying involves several stages:

-

Harvesting and sorting of wood . Smooth logs are selected, with no traces of rot and pest beetles, with minimal external damage (knots and cracks).

-

Forced Drying . The wood is dried in vacuum drying chambers, which helps to improve its quality (to avoid strong cracking). The process improves aesthetics and increases the lifetime of future lumber.

-

Preparation . Peeled bark logs are calibrated, cut into boards of the desired size; substandard rejected.

-

Profiling .On a longitudinal milling machine, a timber acquires a characteristic profile formed by two guides (a thorn-groove system). The form allows you to qualitatively connect the elements without using additional fasteners.

-

Drying . The process allows to obtain lumber with a moisture content of 12-16%, as provided for by the norms of SNiP.

The advantages and disadvantages of building materials

To make housing energy efficient is one of the main goals in the design of any home. Scandinavian engineers, by proposing a house technology from a mini-bar (another name for the material is a thermal bar), simultaneously solved several important tasks. Material for construction of country houses with this technology offers the following advantages:

-

Energy efficiency . Heat losses at home are minimized.

On our site you can find the most popular projects of houses from a mini-bar from the construction companies presented at the exhibition of houses "Low-Rise Country".

-

Cost . The house requires much less lumber than the classic timber construction. Mini-bar is almost twice as cheap as glued lumber.

-

Strength . The reliability of the building is not inferior to the house of solid profiled timber.

-

Versatility . The material is suitable for the construction of any buildings, from the cottage to the doghouse.

-

Quality . Due to the drying and high precision of manufacturing the structural elements of the wall, they have precise geometry and give minimal shrinkage (2-3%, from a common bar or log - 10-12%). The house can be settled immediately after construction.

-

Environmental friendliness . By production of a mini-bar glue or silicone is not used, thanks to which the walls have the possibility of adjusting the indoor microclimate.

-

Aesthetics . The country house from a mini-bar will look especially cozy thanks to the natural invoice of wooden surfaces. The walls of the house do not have to additionally level, grind or trim.

The production of houses from a minibus has minuses:

-

Material Restrictions . The length of the wall without cuts does not exceed 6 meters, which is associated with the peculiarities of production. Proper design allows you to bypass this drawback.

-

Material care . Like any wooden material, a mini bar needs periodic maintenance. To improve the bio-and flame-retardant properties, building material is treated by impregnation during the construction phase and during operation.

On our site you can find contacts of construction companies that offer the service of building houses from a mini-bar. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Pros and cons of houses from a double mini-bar

The first buildings from a mini-bar appeared in Sweden and Finland. Following the descendants of the Vikings, the advantages of the technology were appreciated in those countries of continental Europe where there are frequent snowy and frosty winters. Protection of joints and connections in such houses from blowing and moisture is provided by the tight fit of the wall elements (an inter-heater insulation is not needed) and a special geometry of the bowls.

The energy-saving characteristics of the house from the mini-bar are complemented by other positive qualities:

-

Saving on the foundation . A house built according to this technology is lightweight and therefore does not need a massive (and expensive) foundation.

-

Saving at installation . Wall elements are lightweight and assembled by hand, because the assembly is carried out without the use of lifting equipment.

-

High construction speed . Construction work on the construction of the house takes from 2 to 4 months.

-

Savings on finishing . Mini-bar is an array of natural solid wood. It is carefully processed and does not need additional finishing.

-

Use of the pier . Competent design allows you to remove communications and electrics inside the structure.

About the production of a mini-bar in the following video:

It might be interesting! In the article on the following link, read about Canadian technology at home.

The disadvantages of buildings from a double mini-bar include:

-

The possibility of uneven shrinkage of walls. The outer and inner surface of the wall are operated in different temperature conditions. Sometimes, if a change in temperature and humidity occurs abruptly, the geometry of the walls can be deformed.The garden house from a mini-bar (single) will avoid a similar fate. For buildings from a double timber the following construction technology will be a guarantee.

-

Possibility of insulation shrinkage . In case of violation of the technological process, the insulation may undergo shrinkage, which will cause additional heat loss.

-

Repair difficulty . Due to the complex geometry of the profile, the wall is difficult to disassemble and assemble without damaging the structural details.

-

The novelty of technology . Not developed uniform standards for the repair of buildings from double timber.

-

Guaranteed low quality unqualified assembly . An attempt to save on qualified professionals will lead to errors in installation and low energy efficiency of a country house.

Technology nuances

The construction of suburban housing technology mini-timber has its own characteristics:

-

Filling the foundation . The finished house does not create a significant load on the ground due to the small mass of wall structures. This makes it possible to use a lightweight foundation. Usually enough shallow tape base; tile, screw and pile foundations are also suitable.

-

Installation of walls . At the same time, two beams are mounted in the row; they form a double wall, which, after filling the gap with an insulating material, becomes a reliable wall structure with specified characteristics.

-

Selection of insulation . For wooden structures, a heat-insulating material is selected that does not limit air circulation. Foamglass, vermiculite (as a mixture filler), polystyrene foam balls, flax and mineral wool are allowed. Manufacturers recommend to insulate a house from a double bar with ecowool that does not allow a dew point (condensation) to form inside the walls.

It might be interesting! In the article next link read about technology arbolit.

-

Laying insulation . To insulate (ecowool), filling the cavity, did not begin to subside under its own weight, fitters use blown equipment with a calculated pressure. Independently provide optimum density is impossible.

-

Features of the finish . The naturalness of the material and the quality of its processing allows you to leave the internal walls in their natural form. For decorative purposes, use a non-toxic varnish (transparent or colored), wax or water-based varnish. Exterior walls need protection from the sun, rain and pest bugs. They are impregnated with stain and fire retardant, varnished or coated with a water-based (water-based) acrylic or latex paint.

About blowing ecowool in the following video:

Myths about double bar technology

Looking for information About the house of the mini-bar, you can find a variety of reviews and judgments. The lack of information about homes built on this technology leads to doubts about their suitability for use in the Russian context. Although the method is not so many years old, he has already managed to acquire stable myths:

-

A house from a double bar - a new technology ; it is not known how he will behave in the long run. The technology, invented in a region with harsh and long winters, has been tested in many European countries. After several decades of operation, the buildings received numerous positive reviews. The estimated service life of houses from a double timber is 80-100 years, provided that the house was built without violating building codes, and during operation it will receive periodic maintenance.

It can be interesting! In the article on the following link read about reinforced concrete panels.

-

Rodents are brought inside the walls of a double bar. Steady myth that has spread only in the Russian segment of the Internet. Mice are trying to settle in any house (and also in the apartment of a multi-storey building). There are no cracks in the walls of a mini-bar, which means that rodents enter the house in the usual way - through technical openings and a basement, and they settle under the floor. To protect against uninvited guests, there are many tricks: the use of w / w slabs instead of strip foundations, the installation of protective metallic ebbs over the foundation, the treatment of internal surfaces with special compounds - and this applies to any home.

-

Shrinkage of insulation is inevitable , which means that the heat-shielding properties of the house will deteriorate with time. Compliance with the technology and the use of eco-wool minimizes the possibility of shrinkage.You can add a heat insulator without dismantling the walls by blowing through the attic load-bearing partitions.

About the house with a turnkey terrace in the following video:

Double timber houses: options for projects

The technology does not limit imagination - the project can be one- and two-story, have any number of rooms, an attic, a terrace, a garage or a veranda. The only fundamental limitation concerns the layout of the premises - it is quite strictly subject to certain rules.

During the construction process, it is not possible to change the design set by the project as in other houses, arbitrarily moving partitions. Together with the walls they form a single supporting structure. In addition, due to the limitation of the length of the beam (6 m) when planning large rooms, support columns are used as additional supporting elements.

A customer who decides to build a house from a mini-bar will receive comfortable and safe housing. Construction companies offer several options for ordering houses from a double mini-bar:

-

Domokomplekt . An option for confident and skillful customers who have an idea about the features of assembling housing from a double beam (the process is complicated when compared to a glued beam or a rounded log).

The wall set (house set) resembles a designer, set numbered parts of walls, ceilings, internal partitions and truss system. Assembly drawings are attached to the sawn timber. At the request of the customer, the set is additionally completed with lags and planks on the floor, window and door blocks with fittings, roofing, and lathing.

-

Basic . Specialists of the company will undertake the arrangement of the foundation (mounting screw or filling tape) and collect the frame. They will also install the roof, doors and windows.

-

Turnkey . The customer chooses a project (on the basis of which the estimate is calculated), concludes an agreement and entrusts construction to professionals. The company transfers the house, completely ready for operation, not demanding completion and finishing. The service involves the installation of utilities (plumbing, electrics, optimal heating system).

Houses from a double mini-bar: prices

The material for the manufacture of double timber is coniferous wood (usually pine), which is distinguished by an optimal price / quality ratio. The cost of the house varies depending on the type of heater. Mineral wool is more profitable in terms of price than ecowool, but loses to it in the long term.

The average cost of a double-log felling (as standard) is 5-5.5 thousand rubles. / m 2 . The cost of a turnkey house will increase to 10-15 thousand rubles. / m 2 .

In the Moscow region, the average prices for country cottages using the technology of mini-timber (turnkey double timber) fluctuate between:

-

Houses with an area to 100 m 2 : 450 - 750 thousand rubles. (winter version, timber thickness 45 or 70 mm)

-

With an area of from 100 to 200 m 2 : 0 , 8 - 1.3 million rubles. (thickness of timber 45 or 70 mm)

-

From 200 to 300 m 2 : 1.4 - 1 , 8 million rubles. (bar thickness 45, 70 or 100 mm)

It can be interesting! In the article on the following link read about aerated concrete blocks.

Conclusion

Construction companies offer houses from a double mini-bar in different styles, from ethnic to modern. The technology, specially developed for use in cold climatic zones, is an alternative to classic wooden buildings, allowing you to get high-quality (reliable and environmentally friendly) housing at minimum cost. And the opinion of the owners in most cases says that it is worth choosing a house from a minibus, reviews on the Internet on the websites of different companies confirm this.