The humid air of a residential area tends to go outside, including through the roof. Laying the vapor barrier on the roof helps to avoid moisture accumulation in the roof structure. The article talks about the varieties, properties and functions of vapor barrier films offered in the construction market. You will get acquainted with the subtleties of the laying technology and the main stages of works on vapor barrier of the roof.

Vapor barrier functions

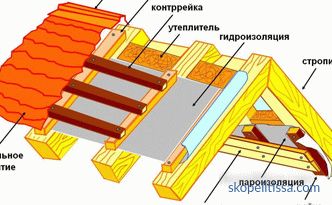

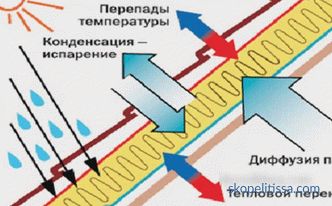

One of the conditions for long-term operation of the roof is a ventilated roofing pie . Air gaps in a properly equipped roof help to regulate the temperature in the dwelling, keeping warm in winter and cool in summer. The air rising from the living room is warm and humid; once in the under-roof space, it cools. In this case, water vapor is collected in the condensate and tends to settle in the roofing pie. Over time, if the roof is unprotected, the heater dampens, and the wood of the rafter frame becomes mold prey.

The solution to this problem is the use of special protective layers in the roofing cake. For the normal functioning of the roof from the outside of the insulation (under the roof covering) waterproofing is laid; under insulation - a vapor barrier sheet, on which the following functions are assigned:

-

Protection of insulation . Vapor barrier, the installation of which is carried out in accordance with the technology, blocks the penetration of condensate into the heat-shielding layer. This preserves the operational characteristics of the material and the effectiveness of the insulation of the building.

-

Roof protection frame . The parobaryer mounted by rules will save wooden rafters from namokaniye and rotting.

-

Increase the service life of the finish coating . The lower surface of the coating is protected from moisture is much worse than the front. Vapor barrier film protects inside out from harmful condensate.

Material Requirements

The main property of all vapor barrier materials is their ability to resist steam penetration. The lower the vapor permeability, the smaller the amount of water vapor that is able to pass through the layer of material, and the better protective properties it has. Three materials are on sale; they differ in two interrelated parameters: resistance to vapor permeability and mechanical strength:

-

1 class . Rigid foil-based materials with the highest vapor permeability resistance.

-

2 class . Materials based on polyethylene or polypropylene.

-

3 class . Soft materials with low (50-100 times lower than 1st class) indicators.

Additional requirements important for durability are also imposed on the film materials roofs:

-

Lifetime . Installation of a vapor barrier for roofs with a service life of 10-15 years is impractical for modern roofing structures designed for 20-25 years. After 10-15 years will go, the vapor barrier will no longer cope with its responsibilities, which will affect the condition of the entire roof. Replacing the film in this case is an extremely troublesome (and expensive) business, often associated with the dismantling of the structure.

-

Operating parameters . Valued materials that can properly perform their functions in a wide temperature range. Most film products are designed to operate in the range of -70 to + 100 ° C.

-

Elasticity . A parameter that is important both for ease of installation and during operation, when a layer of insulation puts pressure on the film.

Types of films

In the construction market presented vapor barrier, created by several technologies and has a different set of properties and service life. Certified products are supplied with instructions describing in detail the parameters of the material and its purpose - familiarity with this information will help you make the right choice. Roofing films offered by the market can be classified in two ways:

-

By material . Modern vapor barrier sheets are made of polyethylene or polypropylene.

-

By functionality . There are vapor barrier, waterproofing and anti-condensate materials. The assignment determines which side to put the vapor barrier on the roof.

Polyethylene films

A single-layer, low-density under-roofing film, which, however, can provide sufficient tightness and protect the insulation from moisture.The main advantage of this insulating material is its budget cost. The main danger is low quality: on the surface of the thinnest films there are frequent manufacturing defects, and the service life is low.

On our site you can find contacts of construction companies that offer roof repair services. You can directly communicate with representatives by visiting the low-rise country exhibition.

Reinforced polyethylene

The vapor-carrying capacity of polyethylene films with reinforcement are comparable to the previous variety. The thin canvas is reinforced with a molded frame made of polymer filaments, which increases its strength and durability. The material has a minus - during thermal lamination (gluing layers) the junction of polyethylene with a reinforcing mesh becomes thinner, forming microscopic cracks. Western European manufacturers have practically refused to issue a reinforced polyethylene film, since it is not able to provide stable blocking.

Polypropylene films (vapor barrier)

Reinforced propylene films compare favorably with polyethylene materials by a longer service life, increased strength and a higher degree of vapor barrier. Polypropylene protection is resistant to ultraviolet radiation and low temperatures, quite elastic at tension and does not tear at the folds; the combination of qualities allows for the installation of water and vapor insulation on the roof in winter.

Bag fabrics

The vapor barrier fabric looks like sackcloth; made of polypropylene yarn laminated with polyethylene melt. Vapor barrier is characterized by high mechanical strength, but poor vapor protection, which makes use of it mainly in the arrangement of cold roofs.

On our site you can find contacts of construction companies that offer the service of completing unfinished houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

Anti-condensate membranes

The material is suitable for both steam and hydro-isolation devices. One side has a rough surface that impedes the formation of condensate. When installing this side is placed inside the building; moisture is removed through the ventilation gaps. The second, smooth side of the material is on top and protects against possible seepage of atmospheric water.

Foil films

Steam insulation sheet with aluminum foil is the most effective barrier to steam; It is widely used to isolate wet areas (kitchens, baths, saunas). The use of foiled materials is most advisable in the construction of a mansard roof. The foil surface is able to accumulate heat, reflecting it inside the dwelling.

It might be interesting! In the article on the following link read about waterproofing choice on the roof.

Diffusion non-woven membranes

Technological material made from specially perforated polyethylene or polypropylene. The smallest diffusion holes of the membrane let the air through with water vapor vapor, but retain water (drops or condensate). Regardless of the technology and material of which the membrane is made, it will still show "breathing" properties, ensuring diffusion (penetration at the molecular level) of water vapor with parallel protection from condensate. The following types of nonwoven membranes are distinguished:

-

Diffusion . Such materials are characterized by a lower carrying capacity, which requires mandatory arrangement of ventilation nets (they are not laid directly on the insulation). Diffusion membrane spread out from the outside in relation to the insulation; only in this case will the vapor be removed from the roof structure, keeping the thermal insulation dry.

About the types and selection of vapor barrier in the following video:

-

Superdiffusion . They are characterized by high vapor permeability, which allows the membrane to be laid directly on the thermal insulation layer. There are single and double sided membranes. In the first case, it is important that the vapor barrier is laid in a strictly defined way - the right side inside. In the second case, the material is spread arbitrarily (it does not matter which side is on top or below).

Subtleties of vapor barrier installation

The main issue that arises when installing vapor barrier for the roof is which side to lay the material and in which part of the roofing pie. Location depends on the type of roofing construction:

-

Insulated attic and mansard roof .In this case, it is important to protect the insulating layer from evaporation from the lower rooms. Therefore, the film is spread under the insulation (from the inside), on the truss structure or rough coating. The sheets of rolled material are laid horizontally and overlapped, fastened with nails or staples.

It might be interesting! In the article next link read about waterproofing film.

-

Cold roof . If the roof remains uninsulated, but further warming is planned, the best solution would be to use reinforced steam and waterproofing. The film is fixed on the rafters or board flooring (if the roof has a small angle of inclination, so you can avoid sagging material). The method is also suitable for a roof with a complex (broken) structure.

Any certified vapor barrier material is supplied with an instruction manual. It provides all the necessary information for laying a vapor barrier on the roof; which side the material is located depends on the layer responsible for blocking water vapor. The general rule can be formulated in the following positions:

-

Double-sided (superdiffusion) membranes , ordinary and reinforced polyethylene films have the same properties on both surfaces. Such materials can be laid on the insulating layer by either side.

About diffuse vapor and waterproofing in the following video:

-

Dual Layer The anti-condensate film is spread out to the smooth side to the insulation, and the rough to the source of warm, humid air to the living quarters.

-

The foil film is placed in a metal layer to the living quarters so that it can return some of the heat inwards, increasing the building's thermal efficiency.

-

Diffusion double-sided membranes provide the roofing cake with the ability to "breathe". If the membrane has both surfaces the same, it fits either side. If you chose a one-sided membrane, the data on the front and back surface should be clarified with the manufacturer (in most cases, the membrane is adjacent to thermal insulation with a rough surface).

It might be interesting! In the article on the following link, read about the types of insulation for mansard roofs.

Steps for installing a vapor barrier layer

Follow the installation instructions specified by the manufacturer; at the same time, the rules allow the laying of film materials both before and after the arrangement of the roofing pie. The progress of the installation of the vapor barrier is as follows:

-

Before installation, you must familiarize yourself with the instruction from the manufacturer, determine the side of the material whose function is contact with steam.

-

Pavement method is chosen, horizontal or vertical. Most manufacturers allow both schemes; In the manual you can learn about acceptable options and details of the layout. The direction of the layout is affected by the slope of the slopes. On a flat roof roll roll out horizontally, perpendicular to the rafters. On a steep roof, the film is laid along the rafter legs.

-

With any mounting method the material is laid with an overlap of , the magnitude of which is often indicated on the edge of the film. Other values are indicated in the instructions (which depends on the steepness of the structure).

About the membrane mounting technology in the following video:

-

The main condition for the installation is the film is fixed without tension , with a sag of approximately 2 cm. A reserve is created due to the ability of the wooden frame to change its dimensions with the change of seasons (with a change in humidity); otherwise, there is a risk of film rupture.

-

For horizontal mounting , laying is carried out from above (from the ridge). Stripes are laid with a back overlap (the lower band overlaps the upper one), for additional protection of the insulation; they are joined with scotch tape and fixed on the structure with galvanized nails or a stapler.

-

If the heat insulation layer is loose, the rolled web is fixed with the help of laths , which are antiseptic without fail.

-

Special attention is paid to places of junction (attic windows, hatches, pipes, ventilation channels); they are isolated especially carefully.

It might be interesting! In the article next link read about a country house in the Indian province.

Conclusion

The use of improper vapor barrier, as well as errors during its installation, lead to a sad result - the heater becomes saturated with moisture and loses its heat-shielding properties, and the condensate begins to destroy the wooden roof system. In neglected cases, the roof freezes through, the ceiling finish loses its appearance, and an unplanned overhaul arises before the hosts in full growth. To avoid unnecessary trouble and money, a competent choice of a vapor barrier sheet and compliance with the technological rules during its installation will help.