A flat roof means that the roof is almost in a horizontal position. This imposes its own advantages and disadvantages in waterproofing a flat roof. Pros: the construction of the roof, which can be used at its discretion, ease of installation and low cost of the roof. Cons: the possibility of leakage due to the small angle of inclination. To eliminate the deficiency will require a responsible approach to the issue of waterproofing.

The role of waterproofing as part of a roof

If a flat roof does not have high-quality waterproofing, this will lead to further leaks. The main visible sign of a deficiency is water that drips from the ceiling. This feature is external, the consequences also arise in the space under the roof:

-

destruction of the base of the roof;

-

deterioration of the insulation;

-

wall wear;

-

fungus reproduction (this leads to an unpleasant smell, threats to health, and so on).

If the waterproofing of the roof is made qualitatively, then it will not allow moisture to penetrate into the enclosed space, violating the integrity of the structure.

How should waterproofing be placed

The waterproofing layer will be located at different levels . It depends on the type of roof plane, which can be traditional and inversion.

Traditional implies finding insulation under waterproofing. If the area above the structure is not further exploited, it becomes sufficient, and the waterproofing is a roofing coating. If the traditional roof will be operated, then you will need to install a layer to protect the waterproofing.

Under an inversion roof, the order of the layers changes. Hydrobarrier set under insulation to protect it from external stimuli (moisture, sunlight, high temperature amplitude, precipitation).

Requirements

The procedure for waterproofing a flat roof should take into account two basic requirements:

-

The layer must completely protect the roof from moisture.

-

The surface should be inclined a few degrees to prevent the accumulation of fluid in the center.

On our site you can find contacts of construction companies, who offer roof repair service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Materials for waterproofing

The peculiarities of the lack of a large inclination of the roof make the builders install a special waterproofing. The material must constantly protect the roof from the incoming moisture, while there should be no open seams. Below are the most common coverage. Each of them has its pros and cons.

Bituminous rolled coatings

From a large number of representatives from this group, ordinary roofing material is distinguished due to its popularity. In fact, the material is cardboard, which is impregnated with bitumen. One of the most budget materials that can be used for roofing. But the term is rarely more than 7 years. The reason for rapid wear is the temperature difference and the effects of precipitation.

At high temperatures, the usual ruberoid begins to crack. Because of this, water begins to fall into the cracks, destroying the cardboard - the main material of the structure. After this, the owner must replace the cover. But simple installation, the essence of which lies in gluing rolls, and low cost.

Normal ruberoid has modifications. If you choose modern species as a material, they will differ in their increased service life and quality.

Instead of roofing felt, you can also use rubemast, an analogue material made of cardboard or fiberglass. Differs in the increased thickness of a bituminous layer. Installation is possible in two ways:

-

Pasted with mastic.

-

It is glued using a thermal direction.

One more progressive analog of roofing material is euroroofing material. Instead of cardboard, the inner base is made of fiberglass or polyester. Also used an improved composition. Bitumen is impregnated with polymers (rubber and polyethylene wax). This allows you to improve the resistance to temperature changes, mechanical stress and precipitation.

For the installation of roll coatings it is necessary to prepare the base. The roof is cleared of debris, after which it is leveled. Next, a layer of soil is applied, the role of which is fulfilled by a bituminous mixture. When the ground completely hardens, it begins the installation of the waterproofing itself.

When using roofing paper, the following algorithm is followed:

-

Adhesive mastic is applied.

-

The edges of the web are glued onto the mastic, after which the roll is rolled. At the same time monitor the absence of air bubbles.

-

The edges of the laid web are leveled.

-

The laid canvas should be pressed as hard as possible to the surface. To do this, use the rink.

-

The next strip of the sheet is glued in, which should go 10 cm overlap. The place where the sheets are joined is processed with mastic.

-

After covering the entire area, a second layer is applied to the first layer of the canvas. In some cases, the number of layers may be three or more.

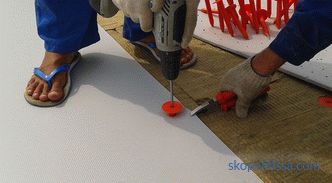

When using bitumen material, the following algorithm is followed:

-

A roll is put in for further direct rolling.

-

The bottom layer heats up, as does the surface of the screed, which is necessary for a tight fit.

-

When the sheet is heated, it is rolled out so that air bubbles or folds do not occur.

-

The laid part of the roll is rolled up with a roller with a weighting agent.

-

When the entire first roll is laid, the second roll overlaps by 6 cm in a similar way.

-

The next layer of roofing felt is laid. If necessary, there may be more than four.

If an euro-ruberoid is used, the procedure is similar. The only difference is in the number of layers: two coatings are enough.

This can be interesting! In the article on the following link read about the ventilation of the roof.

Polymeric membranes

Polymeric membranes are more expensive, but also practical material. These are elastic sheets that easily withstand high humidity and precipitation.

Membranes are divided into several types, but three main types are defined:

-

PVC - made of the same material, reinforcement of polyester yarns, allowing to make a coating resistant, due to the material used, they are distinguished by high fire resistance;

-

EPDM - made of synthetic rubber, in some cases can be reinforced with polyester reinforcement. Reinforcement is required for exposure to strong winds and heavy rainfall. Differ in elasticity and small weight.

-

TPO - made of rubber, can be used with reinforced polyester silt mesh. Distinctive features are high service life and environmental friendliness.

Membranes are attached to the roof in one of three ways. To eliminate leaks, the strips are welded with hot air. In some cases, can stick to each other.

You can see the video on the installation of polymer membranes:

It can be interesting! In the article on the following link read about what kind of roofing is better for a private house.

Ballast fastening system

The mounting system implies the retention of membranes by the existing ballast, the role of which can be played by the material in a loose or piece form.

Algorithm of work:

-

Membranes spread throughout the roof and stretch out of tension.

-

Each canvas should overlap the previous one by 10 cm.

-

Canvas are welded together or glued.

-

Telescopic fasteners should be installed around all protruding parts of the roof.

-

A layer is placed to separate the waterproofing and external influences.

-

Ballast is distributed over the roof surface.

Advantages of roof waterproofing using ballast technology:

-

cost-effectiveness;

-

installation speed;

-

weather resistance.

Ballast system deficiencies:

-

difficult repair process (in case of any serious damage, waterproofing will have to be re-installed over the entire area);

-

The roof must be prepared for high loads.

Mechanical Mount

Mechanical Mount is most common, often used on lightweight structures. Fixation occurs due to the membranes that are attached to fasteners or rails.

Work Algorithm:

-

The first stripe of the cover is spread.

-

The strip is fixed with telescopic fasteners.

-

The next sheet overlaps at least 12 cm.

-

The seams are joined by welding or glue.

The advantages of mechanical fastening:

-

low weight;

-

mounting speed.

Adhesive fastening

The most non-prevalent system , since it is the most expensive. But it must be used if the roof can not withstand a lot of weight. The membranes are fixed with bitumen mastic or glue.

Algorithm of works when using glue fastening:

-

Membranes roll down from the edges to the center of the roof.

-

Glue is applied on the substrate itself, and not on the canvas.

-

The membrane web is unrolled, smoothed and pressed.

-

The following canvas is overlapped by 10 cm.

Advantages of adhesive fastening:

-

wind resistance ;

-

can be used on any roof;

-

low weight.

Disadvantages of adhesive mounting:

-

cost.

This can be interesting! In the article on the following link read about the waterproofing TechnoNIKOL.

Mastics

Mastic used for waterproofing is applied to the base of the roof. This allows you to get a coating without seams, through which water could get into the roof.

All mastics are divided into cold and hot. It depends on softening and hardening temperatures. If hot mastic is used, the composition is heated to 160 degrees Celsius, and then spread over the surface. If cold mastic is used, then it is not required to be heated, but immediately applied to the surface. Heating is required only at low temperatures, for example, if the work is carried out at 5 degrees and below.

Regardless of the type of mastic, it is supplied in a liquid state. The curing process begins only after interaction with air. If you want to increase the strength of the structure, then fiberglass or fiberglass mesh is laid between the layers.

Spray waterproofing

Spraying rubber-bitumen emulsion is one of the newest methods protection against liquids. After solidification, the sprayed emulsion turns into an elastic "rubber", which perfectly repels water.

Spraying of the material is required once, which allows one layer to be 3 mm thick. But for the spread of the emulsion will require the installation of airless spray. Most often, sputtering is used in the construction of large commercial buildings, since one day of work allows the emulsion to spread over an area of 1,000 m 2 . Antennas, pipes and other protrusions are enveloped by the composition, which allows the use of emulsion on complex configurations.

Clearly about the proper waterproofing of a flat roof, see the following video:

It might be interesting! In the article at the following link, read about waterproofing the floor in a private house.

Total

In order to create high-quality waterproofing of a roof in use, the surface must have a slope. Layer that fits the canvas, should not have gaps or gaps. The choice of material depends on the nuances of the roof (where it is located, how much weight it can bear). With proper sequential work, you can achieve high-quality protective layer of waterproofing.