The use of wood in the interior of a house has a long history; it is known that the palaces of the pharaohs were already decorated with wooden panels. In Europe, such a decoration could initially be found only in the mansions of aristocratic persons; By the middle of the 19th century, panel walls had become commonplace in more modest dwellings. In the middle of the last century, wooden wall panels were considered an old-fashioned decoration, but then, thanks to the emergence of new technologies, they received a rebirth and became an actual and sought-after method of decorating interior space.

Why wood panels are needed

The use of such a finish can pursue different goals, in the number of which includes:

-

Style decision . The most obvious and common cause. Wood trim fits perfectly in any style; its use ennobles the room, giving the atmosphere sophistication.

-

Zoning of space . Wood panels are the easiest way to set the tone and create a single space (or vice versa, to select its part).

-

Utilitarian solution . Under the skin it is convenient to hide engineering communications and all kinds of cables; the room immediately begins to look not only beautiful, but also neat. Sometimes plating is the easiest way to disguise wall defects.

-

Improved performance . Wood has its advantages: it improves the sound and heat insulation of the room; it is a durable material that is periodically refreshed - painted or varnished.

Wooden panels: types and dimensions

Decorative walls panels can be conveniently grouped by production material; The following types of products are on sale:

-

From solid wood . High-quality finishing material, which is in constant demand. Panels made of valuable breeds occupy a worthy place in the interior of libraries and classrooms. A wider application found panels of less valuable varieties, often intended for painting; they can be seen both in living rooms and in the corridors. This finish is not suitable for rooms with high humidity.

-

Chipboard-panel (from chipboard). The budget option, which is obtained by hot pressing of sawdust mixed with binder resins. The front surface is glued with veneer or wooden mosaic; in another embodiment, painted after installation. Chipboard panels improve thermal insulation of the room, but are characterized by limited moisture resistance. This property excludes their use for finishing rooms with high humidity (kitchen, balcony).

-

Fiberboard Panels . Like chipboard, they are formed by hot pressing, but they have lower weight and higher resistance to moisture, since they contain wood fibers. MDF is a type of MDF of average density (popular buaser panels are made of this material). The edge of the parts has a dense structure, the surface is laminated, and they are indistinguishable from solid wood products. Information on moisture resistance can be found in the original packaging.

-

3 D -panels . Separate details from the massif of different breeds are glued onto the plywood base by hot pressing; the result is an unusual product with a complex profile. For production, only valuable and high-strength wood species are used, which (together with manufacturability) explains the high cost of this finishing material. The surface is treated with wax or varnish; the formed film serves as reliable protection against moisture and pollution.

-

Bamboo and rattan . Lightweight and moisture-resistant, they are not used as often, mainly for interiors in an exotic style (Asian, African) or country style.

The shape of wooden panels allows you to divide them into the following groups:

-

Rack . The products of the extended form which are a kind of lining. The length of such parts is in the range of 2.4-3.7 m, width - 12.5-30 cm, thickness is also standard - from 0.8 to 1.2 cm.

-

Leafy . Large panels, whose length reaches 2.44 m, width - 1.22 m, thickness - up to 0.6 cm.

-

Dial-up . Products have the form of squares with a side from 30 to 98 cm.

The shape and size of the decorative panels are chosen based on the geometry of the room. Rack products have the ability to visually increase the size of the room. The sheet material is ideal for spacious rooms, with the help of composing parts you can focus on part of the space.

On our website you can find contacts of construction companies that offer insulation services and exterior decoration houses turnkey. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Materials of the front side

A wide range of wood varieties are used in the production of decorative items. Different types of panels use wood in different ways:

-

Wall panels made of natural wood . Original products are made from an array of species such as oak, walnut, teak, ash, beech; budget option - pine and spruce. The surface can be varnished and preserve the natural color, be painted or artificially aged (with a patina). There are also more exotic options: granary wall elements from old, additionally treated wood, from the edge of the board, from chipped wood (with a 3D effect).

-

Veneered panels . For the base, MDF boards or pine and spruce plywood are used (for more expensive veneer). Veneer (a thin sheet of natural wood) is made from both common species (walnut, cherry, Karelian birch, bog oak), and from exotic and therefore more expensive (rosewood, wenge, tineo, eben, rosewood, zebrano). Popular products with fine-line veneer (fine-line), a type of reconstructed veneer with texture and color of valuable species. A wide choice of materials in combination with the ability to change colors creates unlimited possibilities for design.

-

Natural birch bark . The bark is glued to the base and varnished (usually with a matt varnish). The paneling with a natural black and white texture makes the interior less formal.

-

Paneled panels . Classic panels (often called boiserie) are used to create a respectable interior. They are made of solid wood or MDF and veneer (often to order, according to the size of walls, openings and door portals). The design uses such elements as one or several frames around the perimeter, a figured panel, a connection through a pilaster.

It can be interesting! In the article on the following link read about concrete panels.

Finishing methods for the front surface

There are several ways to finish the front surface:

-

Veneer . Facial veneer (thin sheet of wood) is selected for quality and appearance. If valuable wood species are used as veneer, then the panels become indistinguishable from elite products, but cost less.

-

Lamination . The front surface is laminated (covered with film), after which it becomes matte or glossy. The coating not only improves the appearance, but also protects the base from dust, ultraviolet radiation and mechanical damage.

-

Lacquer or wax . Acrylic varnish (colorless or tinted) and wax are reliable, long-lasting ways to protect a wooden surface from moisture, dirt and sunlight. They preserve the natural texture of wood, which is good for the eye. Waxed panels repel water well, but need more thorough and regular care. Popular and lacquerware, among which there are both glossy and matte, and more exotic (mother of pearl) options.

-

Other options . Wall panels made of wood are decorated in other ways. For decorative decoration embossing is actively used when the pattern is applied to the panel by pressing. Gilding, mirror inserts, carving are used. Panels with complex geometric relief, made with the help of milling, are used for decorating interiors in classical and English styles, often for modern or art deco styles.

It can be interesting! In the article on the following link read about wood wall panels.

Ways of placing on the wall

Paneling is a creative process. Almost unlimited choice of wood types, colors and textures allow creating unique interior in every house. With all the variety of options, the panel finish is located in three ways:

-

On a part of the wall . The traditional method, which has been widely used in European dwellings since the end of the 19th century, has been preserved in state institutions, offices, and classical mansions. The panels occupy the lower part of the wall, and their height is governed by a simple rule: the height of the finish should be one-third the height of the wall (not more than 120 cm).If this rule is violated, the ceiling (and with it the room) will look visually lower than it actually is. Bottom trim is a popular solution for the hall, living room, dining room and corridor. Occurs in the kitchen, in the nurseries and bathrooms.

-

All over the wall . Full wall decoration is used when the owners want the room to look solid and status. That the room had a proper look, use panels from the massif of a tree. Reception is suitable for registration of "male" rooms: office, library or billiard room.

About the properties of wood panels in the following video:

-

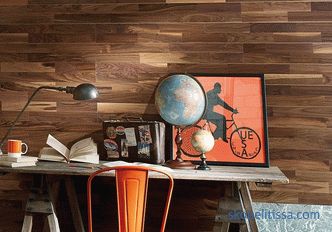

Decorative Accent . Facing a fragment of the wall does not weigh down the space and does not reduce the size. In this way, it is possible to effectively zone a spacious room, and the choice for this role even of expensive panels does not hit the pocket too much. The method is widely used in the design of the hall, living room and bedroom.

It can be interesting! In the article on the following link read about the wall sandwich panels.

Advantages and disadvantages

Many choose wall panels among the various methods of wall decoration, wood in this case is the most advantageous option. The wooden surface is well combined with most materials, and therefore relevant in any interior. The advantages of wood veneer include the following positive qualities:

-

Aesthetics . The use of wood brings natural beauty to the interior and transforms the room.

-

Durability . Quality products retain the original appearance for several decades.

-

Variety of models . The number of types of products offered by the modern market is amazing. If none of them is suitable, the option will be the manufacture of panels to order.

-

Variety of prices . You can choose products with an optimal price / quality ratio for any budget.

-

Quick Installation . Before installation, you do not need to level the walls, nor do you need an expensive tool.

-

Practicality . Caring for a wood-trimmed surface will not be time consuming, dust is easily removed with a cloth. Some varieties of material will require periodic renewal, the surface is refreshed with varnish or wax.

-

Thermal insulation properties . Wood has a low thermal conductivity, walls paneled retain heat better.

-

Additional sound insulation .

-

Environmental friendliness . Certified panels, processed in compliance with technological standards, will not cause harm to health.

About the manufacture of veneered panels in the following video:

Disadvantages are:

-

Restrictions on the use of . Wood, as a natural material, reacts to excessive humidity. To keep the wooden finish for a long time looking, it is used where a stable level of humidity and temperature is maintained.

-

Fire Hazard . The disadvantage of any wooden material. When choosing wall panels, you should pay attention to the class (the higher it is, the more dangerous it is for a person). The ideal choice would be products whose documents have a low level of ignition (class B1), low flammability and toxicity (G1 and T1), a low level of smoke formation (D1).

Selection Criteria

Before purchasing wooden wall panels, several problems are solved:

-

Define budget .

-

Determine general characteristics - material, color tone, method of finishing.

-

Check compliance with SNIP . Favorite panels are studied in more detail: the size and composition is indicated on the label, flammability and toxicity - in the certificate. Ensure that the model is intended for residential use.

-

Check certification and warranty . During work, you may find that there are defects on individual parts — a damaged surface, damaged connecting locks, and differences in color. Substandard goods are subject to warranty replacement.

-

Select the fastening method . Wooden wall panels (many of which have a groove / tongue or groove / groove connection) can be fixed in two ways. If the surface on which the panels are to be mounted is ideally flat, it is not forbidden to use special glue (after making sure of its suitability for this work). In most cases, use mounting hardware that the panels are completed with the purchase.

About the installation of 3D panels from split wood in the following video:

This can be interesting! In the article on the following link read about wall panels.

Decorative wood wall panels to order

Custom panels help you to create an exclusive interior in the chosen style. Construction companies provide a comprehensive solution to this service, offering the following features:

-

Model selection . You choose a model from the catalog or you are given a task to create an individual sketch (the latter is possible not in all companies, and is paid additionally). In addition to the classic boiserie, some workshops take orders for 3D panels with unusual mosaic relief, or modern versions of chopped wood or barn wood.

-

Reconciliation . The specialist conducts measurements, studies the features of the layout, clarifies the wishes of the owners in terms of the size and design of the panels, the material of manufacture and the overall style of the premises. The cost is calculated, after which the contract is signed.

-

Version . In terms determined by the contract, the installers sheathe the walls with panels that can be simple or completed with decorative carved elements (platbands, cornices, baseboards, borders). The quality of work performance is confirmed by the guarantee

On our site you can find contacts of construction companies that offer interior redevelopment services. You can directly communicate with representatives by visiting the low-rise country exhibition.

Conclusion

Wall cladding with decorative wooden panels becomes a popular type of finishing work in a country house. An increasing number of owners prefer this method as the fastest, affordable and quality. Wooden panels will be a perfect decoration for your living room, bedroom or office; more than a dozen years they will maintain the comfort and respectability of housing.

Rate this article, we tried for you