Modern manufacturers produce a large amount of building materials to cover the roof. Today we will tell about the novelty - plastic roofs. This is a relatively new material on the Russian market, about which you should learn more. After studying the information from the article, you can get information on what ingredients plastic is made for the roof, as well as learn about its main advantages and some disadvantages.

Materials used

Plastic roofing has recently appeared on the Russian construction market, but It is rapidly gaining popularity due to its positive characteristics. But before listing the advantages of the structure, you need to understand what the plastic roof is made of.

Plastic roofing materials:

-

Polyvinyl chloride . Abbreviated - PVC.

-

Polycarbonate .

-

Acrylic .

-

Fiberglass .

These materials are used in the following works:

-

Construction of canopies, carports or parking spaces .

-

Glazing of horizontal or vertically located platforms, partitions .

-

Construction of shopping centers .

-

Construction pavilions or office buildings .

-

The construction of agricultural structures - greenhouses, hothouses, winter gardens .

Each variety has individual characteristics, and therefore should be considered each material is more detailed.

Polyvinyl

PVC is divided into several varieties in terms of design. On sale you can find a wavy and trapezoidal profile. The choice of forms is caused by increased strength.

Plastic roofing for PVC will be completely protected from the negative effects of rain, wind and snow.

For the manufacture of material using a special method called extrusion. This means that PVC in the molten state is forced through special molding holes.

Main advantages:

-

It is important to note that in the manufacture of material, manufacturers of do not use plasticizers , which can have a negative impact on human health. This material is environmentally friendly and completely harmless;

-

Plastic density is 1.4 g / cm ³. From this we can conclude that PVC has great strength , and also has greater resistance to shocks;

-

The advantages include a large choice of colors .

This provides customers with an opportunity not only to build a structure, but also to give he has an individual and attractive appearance;

-

If you choose polyvinyl chloride during construction, you can be sure that the material will last

or a little more for 15 years, but with proper operation. Of course, the metal tile keeps on the roof much longer, but at the same time PVC during the specified period will retain its original appearance. This can not be said about other types of roofing materials; -

It should also be noted that PVC is resistant to various acids, gasoline, alkalis and kerosene ;

-

If moisture gets on the surface, the material will retain its original appearance and will not swell ;

-

Plastic has a greater heat resistance . Operation is allowed at positive temperatures up to 80 degrees Celsius;

-

By purchasing PVC to cover the roof, you can save a lot of money on installation work;

-

Users note that it is very easy to exploit the material, since it is treatable . It can be milled, cut or drilled. Also, without problems, it will turn out to bend if you warm it.

Despite the significant list of advantages, polyvinyl chloride has some disadvantages:

-

Although plastic PVC roofing sheets can withstand high temperatures when heated, but their colors will become darker than the original. Also material will lose elasticity .

-

Polyvinyl cannot be protected from mechanical damage , and therefore it is scratched and loses its aesthetic appearance during careless use.

-

The assembly work should be done only in the warm season, since PVC gets very slippery when snow enters, and this can lead to workers' injuries.

-

To make the installation, also you will need to additionally purchase special pads that will be placed in the junction with self-tapping screws.

-

Polyvinyl chloride, produced in the form of a sheet, must not be laid on the roof, with a slope of less than 6% .

Polycarbonate

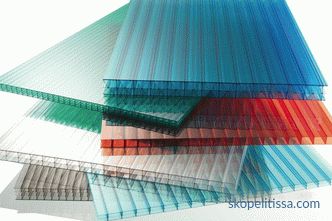

Polycarbonate is a polyether consisting of dihydric phenols and carbonic acid, belonging to synthetic polymers. There are several types of material:

-

Cellular plastic for the roof . These are panels that consist of a large number of cells.

It is for this reason that the material has such a name - it is very commemorates the honeycomb . The manufacturer manufactures polycarbonate for the roof, through which the light must penetrate inside the room;

-

Monolithic . This material is larger than the previous variety, because there are no facilitating cells inside. The thickness of the monolithic polycarbonate - 12 mm. The material is very durable. This is evidenced by various tests. It was experimentally proved that monolithic polycarbonate can withstand even a pistol shot - there was no exit hole. It is important to note that this type of coating is not deformed at all during operation. Therefore, the roof is used if the structure is often exposed to strong winds.

Main advantages:

-

Polycarbonate without much effort can be bent into the required shape by heat treatment. This is very important if the coating is to be used on a building with a complex geometry;

On our site you can find contacts of construction companies that offer services for designing and repairing roofing . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Cellular polycarbonate weighs very little - about 12 times lighter than glass of similar size. This simplifies transportation and installation;

-

Both types of polycarbonate are coated with a special protective layer that reduces the negative effects of ultraviolet rays. But the light in the room will pass without problems, since the transparency of the material - 86%;

-

Polycarbonate is used at temperatures from -40 to +120 degrees . It is for this reason that it is suitable for any climatic zones;

-

If an open flame hits the material, will not ignite and will not begin to emit harmful substances. From this it follows that the coating is absolutely safe for humans and animals;

-

The monolithic coating can be used on buildings that are in harsh climatic conditions . Polycarbonate withstands heavy hail stresses, and also has greater tensile strength. For this reason, gardeners use this particular type of roof for arranging a greenhouse.

Scope:

-

construction or city sheds;

-

covered parking and awnings;

-

parking spaces;

-

public transport;

-

home constructions .

Acrylic materials

Acrylic is a glossy and transparent material made on the basis of polymethyl methacrylate. It, like the previous versions, is often used as a roof covering. For the manufacture of acrylic sheet used extrusion method.

The coating made of acrylic has a high impact resistance. But at the same time it is elastic enough so that the master could give the necessary form to the structure. To achieve these indicators, manufacturers add elastomer (a viscous and elastic polymer) during production.

Main advantages:

-

Long service life - up to 30 years .

-

Of all the materials described, acrylic has the highest degree of transparency . This figure is 92%.

-

The mass of the material is extremely small - about 3 times lighter than glass.

-

But, despite the fact that the material is much lighter than glass, its impact resistance is much higher than that of this material.

-

The product is environmentally friendly , and is completely safe for the human body.

Application:

-

Construction of facades .

-

Construction gazebos, terraces or carports for vehicles .

-

Production of canopies .

Typically, such materials are used in designs where you need to maintain very good natural lighting.

On our site you can familiarize yourself with the most popular projects of "small forms" for a private house - from construction companies represented at the exhibition "Low-Rise Country".

Fiberglass slate

Plastic slate is made from polymer. It consists of polyester resin, which is reinforced with fiberglass.

In other words, polymer slate is a material reinforced with a reinforcing layer.

The strength of the material is significantly higher than that of previous roofing options. In the sun, it retains its original appearance - does not turn yellow and does not fade.

Specifications:

-

Thickness from 0.8 to 2 mm .

-

Light Transmission - 92% .

-

Can be used up to 30 years .

To purchase quality products, you need to select very good and proven manufacturers. Eterus and Brianzaplastica have positively recommended themselves.

Main requirements for plastic roofs

Very strict requirements are imposed on a roof made of transparent plastic. The main ones are:

-

Good protection against exposure to ultraviolet .

-

Providing high-quality ventilation , as well as fast smoke removal if a fire starts.

-

High-quality heat, noise and waterproofing .

-

Maximum structural strength .

-

Possibility of snow removal in winter .

Polyvinyl chloride, acrylic, polycarbonate and slate meet all these criteria, and therefore are becoming more popular around the world.

It can be interesting! In the article on the following link read about how the roof is made of corrugated .

Advantages of a transparent roof

As is clear from the text, at the moment it is not difficult to acquire a transparent roof. Various firms provide the buyer with a wide range of their products.

But not everyone knows why it is such structures that are valued and why they are recently acquired more often than traditional roofing.

The main advantages of transparent materials:

-

Natural light has a positive effect on the human nervous system . This is a major and important advantage over artificial lighting;

-

Transparent roof visually increases the space inside the room;

-

Not to mention stylish appearance ;

-

The roof will never rust, there will be no mold on it.

From the video you can find tips on choosing and installing polycarbonate:

Price

Having decided to purchase plastic roof, you can count on the price of about 250 rubles per 1 sheet. The final cost will depend on the manufacturer, thickness and type of coating.

It is important to note that in the winter period (due to small sales during this period), many manufacturers offer significant discounts. There is an opportunity to significantly save money, and to pre-purchase material that can be safely installed after warming.

In Russia, the most famous manufacturer of plastic roofing materials is the domestic company Yug-Oil-Plast. As well as users are well served on the products of the French company "Ondex".

From the video you can learn how to use polycarbonate for a canopy:

That might be interesting! link read about project house with a wavy roof .

Conclusion

When it comes to building a roof, you do not have to make hasty conclusions and acquire the first available roofing material. It is advisable to get acquainted with all the nuances of the materials provided, and make a choice in favor of the one that is most suitable in a particular situation.