The basement base of a country house is the basis and support for the load-bearing walls. Its main purpose is to protect the inside of the building from the flow of water and the penetration of cold air. Carefully selected brick for the basement of the foundation eliminates the problems in subsequent operation.

Choosing a brick for a basement correctly

First of all, figuring out which brick is better for a socle, it is worth remembering that it must combine high strength, durability and decorativeness.

These three main parameters are not the only ones. In addition, it is necessary to pay attention to the indicators of brick frost resistance, its minimum water-absorbing ability and resistance to deformation. And, of course, all this is desirable to fit into a small budget.

Do not forget that the selected brick should correspond to the design decision of the house and look beautiful.

Arrangement of the base

When arranging the basement, it is very important to choose a quality material, so the risk of reducing the lifetime of the building is reduced. If the physical properties and technical characteristics of the brick are appropriate, more than one generation will live in the constructed house.

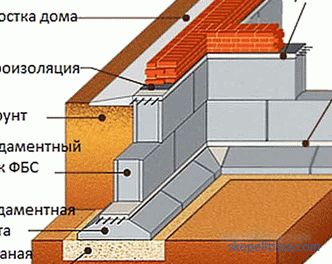

The arrangement of the basement is shown in the following figure:

For its reliable follow operation, during the arrangement it is necessary to observe the following recommendations:

-

The thickness of the basement is determined based on the materials of the walls. For brickwork, a basement with a base of at least 51 cm is needed. If the walls of the house are made of timber, then a width of 25 cm is quite sufficient.

-

When laying a brick base, a properly chosen cement mortar is very important. Optimally meets the requirements of the mixture with the following composition: cement M200, sand and lime. The proportions should be 1: 6.7: 6.7. The mixture is brought to a pasty consistency.

-

The existing system for calculating materials allows you to prepare the necessary amount for the arrangement of the brick base. For 1 m? The basement floor needs 400 bricks (size 250 × 120 × 65 mm) and 30 cm? cement-sand mix

Properties that a brick must have for a base

Given all the above, it is clear that a brick for building a base must have the following properties:

-

increased compressive strength (from 200 MPa);

-

standard sizes - 250x120x65 mm;

-

high environmental friendliness;

-

moisture resistance;

-

with a raised surface.

The strength of a brick ensures the reliability and durability of the basement and the structure as a whole. Standard sizes ensure an even and attractive view of the basement and the whole building in particular.

In addition, the work on the construction of the socle will be less labor-intensive. The absence of harmful impurities in the brick will exclude harm to residents of the house. The relief surface of the brick adheres remarkably to the mortar and prevents the formation of cracks and cracks a, and accordingly cold bridges.

Types of brick base

A brick base can be equipped in three different ways:

-

zapadayuschy;

-

protruding ;

-

at the same level as the walls.

When arranging the plinth plinth, its walls are slightly smaller than the main walls of the building. A base of this type is carried out in case of the need to protect the structure from sedimentary water flowing from above. Most often used in regions with high rainfall.

On our site you can find contacts of construction companies that offer a foundation repair service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The protruding base is constructed with a thicker wall than the walls. In most cases, such a basement is equipped with additional protection from precipitation, for example, metal canopies covering the ledge.

Which brick is suitable for the base

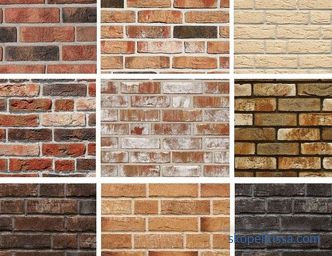

If you follow the standards prescribed in paragraph 6. 65 of the SNiP, then the universal solid red brick is universal for many regions, it is also called a well-burned ceramic brick of plastic pressing. It is manufactured according to GOST 7484-78 and TU and GOST 530-2007.

Solid brick with a high density has a mass of 3-4 kg. Its volume weight is 1500 - 1900 kg / m 3.It is used when it is necessary to organize high indicators of structural strength, sound insulation, thermal conductivity and heat capacity.

It might be interesting! In the article on the following link read about finishing the cap of a private house.

Despite the obvious positive characteristics of such a brick, there are better options, however, they cost much more. We are talking about clinker, fireclay and subspecies of clay brick.

Clinker immediately stands out with obvious advantages:

-

water absorption (not more than 5%);

-

strength (from M250) ;

-

frost resistance (from F100);

-

increased wear resistance.

In some cases, the combined version is practiced, in which the basement is made of red brick, and its facing is carried out by clinker.

The clinker brick is ideal in terms of wear resistance. Its front surface for many years retains its original appearance. According to the characteristics, it far exceeds the red brick, which, respectively, directly affects the cost of the clinker brick. The high price is its disadvantage.

Fireclay bricks are also called fireproof. Accordingly, it has the following characteristics:

-

water absorption does not exceed 3%;

-

starting strength is M25;

-

Increased acid resistance protects against aggressive environmental influences.

Well, the refractoriness that allows the product to withstand extremes of high temperatures. Summing up, we can safely say that the red brick of the brand M150-200 with frost resistance F35-50 is the best option for a socle that can reliably last for hundreds of years.

Clinker bricks and fireclay bricks also well meet all brick requirements for a base, but are much more expensive.

The ordinary clay brick of the brand 150-250 is distinguished by durability, frost resistance and low price. Its significant drawback is a completely unpresentable appearance. Laid out of it, the base clearly needs to be finished.

It can be interesting! In the article on the following link read about the paint for the foundation of the foundation.

Which brick cannot be used for the base

Because of its high hygroscopicity, silicate brick is absolutely not suitable for decorating the base. The base erected from it will gradually collapse, since the silicate perfectly absorbs moisture from the soil and collapses due to the temperature difference.

In just a couple of years, the basement will need a major overhaul. A collapsing basement in turn will lead to the destruction of the foundation and, accordingly, of the building as a whole.

Laying the socle in stages

The process of arranging the socle is sufficient complex and responsible, requiring the participation of professionals. The brick plinth layout is as follows:

-

from the 1st to the 4th row - masonry;

-

5th row - transverse wall;

-

6 row - brick layout;

-

7 row - filling the space with insulation.

Before embarking on masonry, you need to correctly set the corners for the subsequent laying of the base. At the preliminary stage, the solution is not used. This row is set only on the level, since the subsequent rows can no longer be shifted. After the first row is set, measure all the sides, two diagonals, and make sure that the structure is even. The masonry level should be perfect.

The maximum allowable discrepancy should not exceed 2 cm. In this case, the discrepancy can still be corrected with further laying.

After the end of the measurements begin to equip the basement. It is laid out with bricks with a cement-sand mortar having the following proportions of 3: 1: 1 (purified sand, cement, water).

The minimum width of the base is 380 mm. If the wall of the basement involves only brick laying without insulation, the thickness is not less than 500 mm. If foam insulation is assumed to be foam, the basement thickness is 380 mm.

When arranging the basement, the foundation should be 30-40 cm. This width provides a beautiful base, of sufficient height, allowing to equip a large room that can be equipped for a boiler room or utility room.

Clearly about the choice of bricks for the construction of the basement in the following video:

It can be interesting! In the article on the following link read about the foundation on heaving soils.

Conclusion

Summing up, we can say that before arranging the basement, careful measurements must be made, since the choice of materials depends largely on the expected maximum loads.

The best option is a brick. It is warmer than concrete, which greatly improves the comfort of stay and reduces the cost of the subsequent maintenance of an optimal microclimate. To make a base of concrete is unprofitable from an economic point of view.