Every owner aspires to make a country house comfortable throughout the year. The comfort consists of several components, but in many respects depends on warming. One of the most popular materials, insulation, present in the construction market, is insulation penoplex. This plate insulation, although it has almost a century of history, does not give up its position, because it has several advantages over other materials.

A bit of history

A brief history of the appearance of extruded polystyrene foam (the official name of foam foam) as follows:

-

1941 g . Like many other useful things, the material was originally developed for the needs of the army (in this case - for the US Navy). This year, The Dow Chemical received a patent for a new development, and in 1942 it established large-scale deliveries. Moisture-resistant material with excellent insulating properties went to the production of boats and life rafts.

-

1952 g . After the war, the Americans continued to use penoplex, its use has expanded significantly, first in the refrigeration industry, and then in construction.

-

1963 g . Extruded polystyrene has spread throughout Europe and since then occupies a stable niche in the market of insulation.

-

1998 . Extruded polystyrene foam began to be produced in Russia (in the Leningrad region) under the trademark "Penoplex" and was adequately appreciated by builders.

About Production Technology

Extruded Polystyrene Foam (Penlex , XPS) is a related material to conventional polystyrene foam, commonly known as polystyrene foam. Penoplex is also produced from polystyrene granules, but the technological chain has a different look:

-

Mixture preparation . The granules are loaded into the mixer, where they melt under the action of elevated temperature, and after the injection of a foaming agent under pressure, they form the desired homogeneous structure.

-

Molding . The foam mixture passes through extruders (forming holes), is cooled and cut into plates.

-

Result . The structure of extruded polystyrene foam forms many small cells filled with air. Due to the fact that the cells are closed, the material acquires the properties of an excellent heat insulator. The color of the plates is yellow-orange, less often blue.

Advantages and disadvantages of penoplex

How are any building material, penoplex has its strengths and weaknesses. Knowledge of the characteristics of the material will allow using it with maximum efficiency Positive characteristics include the following parameters:

-

Low thermal conductivity . The coefficient of thermal conductivity does not exceed 0.03 W / m · ºК, which indicates a high degree of thermal insulation.

-

Low water absorption . 0.5% by volume for the month.

-

High compressive and flexural strength - 0.27 MPa. This property allows the use of plates not only as a heater, but also as a building material, which is not subject to structural cracking.

-

Low weight . Due to its low density, the material does not load the supporting elements.

-

Wide operating range . The material does not lose properties in the range from -50 to + 75 ° C.

-

Durability . The service life is 30-50 years.

-

Easy installation .

In order for the penoplex to bring the expected benefits, remember About disadvantages (and take them into account):

-

Low vapor permeability . The indicator is worse than the foam, which makes you think about a good ventilation system.

-

Flammability . It belongs to the class G3-G4 (normally-and highly combustible substances).

-

Environmental friendliness . The material is safe for health if it does not contain harmful impurities. The existing variety - self-extinguishing polystyrene foam, is impregnated with fire retardant and can have a negative impact on humans.

-

Extremely low noise insulation .

-

UV stability . Destroyed under the action of sunlight, needs protection during storage.

-

Instability to a number of organic solvents and other substances. These include gasoline, diesel fuel, oil paints, polyester resins, aromatic hydrocarbons, ethers.

On our site you can find contacts of construction companies that offer a home insulation service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Types and sizes of heat-insulating plates

Manufacturers produce foam sheets, the size and specific gravity of which is indicated on the package and defines the limits of use of the material. The following types of slabs are encountered:

-

For walls . Plates with a density of 25-32 kg / m 3 are used to insulate the facade (due to the low vapor permeability of the material, additional vapor barrier is required for the interior). When external insulation non-residential buildings vapor barrier is not required. At the end, it is possible to conduct plastering on a metal grid, or to perform facing with a facade material of your choice (clapboard, siding, ceramic tile).

-

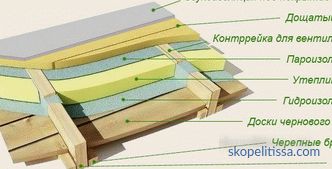

For roofing . It is known that through poorly insulated roof up to 20% of heat is lost. Penoplex "Roof" is designed specifically for the insulation of the roof, pitched or flat. Light and moisture resistant plates with a density of 28-33 kg / m 3 are simply joined without the formation of cold bridges. The material is tough enough to withstand significant installation and operational loads; it is equipped with a groove that provides a tight fit.

-

For the foundation . The increased density of the plates (29-33 kg / m 3 ) allows them to be used for arranging the foundation, basement, garden paths, insulation of a septic tank and engineering communications.

-

Penoplex Comfort . Sheets with a density of 25-35 kg / m 3 have a l-shaped edge, so they are mounted without any problems. Heat insulation plates are widely used in private housing construction (including insulation of baths, saunas and swimming pools), as well as for high-quality insulation of apartments (especially loggias and balconies).

-

Penoplex 45 (GEO) . High-density (35-47 kg / m 3 ) material suitable for use under constant heavy loads. It is used for warming runways, roads (road and rail), exploited roofs, parking lots and pedestrian zones.

There are calculation tables for different regions that determine the choice of sheets of penoplex; thickness in them is a key indicator. The most commonly used plate thickness of 20-100 mm. Depending on the brand, the length varies from 1200-2400 mm, the width is always the same - 600 mm. The number of plates in the package can vary from 4 to 18 pieces.

About the production and features of Penoplex in the following video:

It might be interesting! In the article the following link read about floor insulation in a wooden house.

Methods of fastening penoplex

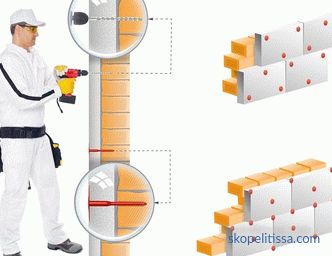

In modern suburban construction, installation of foam panels is carried out in three ways:

-

Using the adhesive composition . Universal method suitable for warming a large surface, facade or basement, followed by plastering.

-

With the use of fasteners . If a significant load on the layer of insulation is not expected, the sheets are attached with plastic dish-shaped dowels. The method is suitable for insulation basement or loggia.

-

With the use of construction foam . The advantage of polyurethane foam - high adhesion (adhesion with the surface) plays an important role in the insulation of the floor, attic floor and walls.

It might be interesting! In the article on The following link read about the insulation of log houses outside.

Warming of the facade: the stages of mounting the plates with glue

The process of warming the facade with foam panels is as follows:

-

Surface preparation . The working base removes dirt and the old layer of lining. If there are spots of mold, they are treated separately (disinfected with copper sulfate). If necessary, the surface is leveled and primed.

-

Installation . Sheets are glued in rows, bottom up, with ligation (with offset) of the seams. The adhesive composition is applied on a sheet of penoplex two lines across. In an alternative way, if the glue is applied to the work surface, this is done in a continuous layer. Each plate is pressed against the wall, its position is checked by level.

About the thermal insulation of the foam roof of the pitched roof in the following video:

-

Sheet cutting . The obvious way, breaking a sheet, is no good, as it gives an extremely sloppy, crumbling line and irrevocably spoils the part. A regular hacksaw gives the best, but also not a perfect edge.The most qualitative result is obtained when using an electric jigsaw. If you need a sheet of a more complex (shaped) form, often use a heated tungsten string (which requires a certain skill) or a thermal cutter. Laser cutting is carried out in the workshop conditions and allows you to get neat and precise details (templates or decorative elements).

-

Optional attachment . It is necessary if the adhesive method showed imperfect results, and the plates move away from the base. In this case, help screws mounted on the corners of the sheets. An alternative method is thermal knobs with wide caps, which are installed in the seam between the sheets and simultaneously fix several elements.

-

Preparation of penoplex for plastering . The heat insulator layer is covered with glue, on which the metal mesh base is fixed (embedded), on top it is additionally aligned with glue

-

Finishing work . After the glue on the reinforcing mesh dries out, they proceed to the finishing plaster lining.

It can be interesting! In the article on the following link read about the insulation of the frame house.

How not to lose money

If the designers and builders do not take into account the physico-chemical characteristics of the penoplex, its strength and thermal characteristics deteriorate long before the end of the service life, which leads to a decrease in the thermal efficiency of the house. The most common mistakes include the following solutions:

-

The use of material with a density that is less technologically sound . Penoplex, like any polymer, is oxidized by oxygen in the air. The oxidation rate (change in chemical structure and deterioration of performance properties) depends on the density of the material. The use of plates with lower density (understandable desire to save) impairs the thermal protection of the structure 2-3 times faster, and this is noticeable in the first 7-10 years of operation.

-

Using incompatible materials . Extruded polystyrene foam plates will be destroyed at an accelerated rate if substances that are hazardous to the structure of the foam complex (for example, oil-based paints containing volatile hydrocarbons) are used during construction.

-

Ignorance of the features of the marking . An inexperienced person, seeing the words “Mark 25” on the package, makes a logical conclusion, in his opinion, that there are plates with a density of 25 kg / m 3 inside. But in technical terms, this is the way denoted material with a density from 15.1 to 25.0 kg / m 3 . Some manufacturers, taking care of maximum profit, supply the lowest density penoplex under this brand (15.1 kg / m 3 , packing plastic density). The result of the substitution quite soon appears on the "warmed" facade - wet stains and mold.

-

Incorrect thermal insulation . Improper insulation leaves an air gap between the wall and the slab material. The design becomes non-uniform, the dew point shifts into the gap. Condensate is inevitably absorbed into a denser material (wall), the thermal efficiency drops, sometimes significantly.

It might be interesting! In the article on the following link read about insulation for walls inside the house in the country.

Conclusion

Each owner, investing significant amounts in the construction of a country house, expects that housing will be for many years, decades to serve faithfully. The reliability of the walls and internal comfort to a large extent depend on properly conducted insulation. Competent use of penoplex will make significant savings in thermal energy (the main goal of any insulation), and, therefore, the family budget.

Rate this article, we tried for you