Torn brick is a type of finishing material that is widely used in cladding facades, fences, arbors. They are decorated with interiors of residential and public buildings, used in landscape design. The decorative qualities of artificial stone, imitating the natural texture of granite, sandstone or limestone with a high degree of certainty, are highly valued.

Briefly on the main

Finished with tattered brick fences are associated with fortress walls, and facades - with medieval castles. Facing fireplaces, arches, corners, columns inside the premises creates an atmosphere of security and peace.

Manufacturers of facing materials keep up with the times, offering buyers a large selection of imitations of various shades, shapes and sizes.

Manufacture and types of torn brick

A brick is called "torn" because one or several of its faces in the production process are destroyed to impart the structure of a natural stone. This operation is performed by cutting the blanks on a special machine or applying decorative chips.

Raw materials and production process

For the manufacture of raw material, screenings of shell rock, granite, blast furnace slag, claydite, brick or glass are used. The components crushed to 3-5 mm are mixed with cement (up to 15%), water (8-10%), dyes and modifiers.

Stones are made by the method of hyper pressing with reduced humidity of the raw material. Under the pressure of 20-25 MPa, the products are molded in special installations. For further strength development, the blanks are sent to the steaming chambers or for long-term drying.

Varieties

The first experience in producing piece materials using the semi-dry pressing method in 1989 was successful in our country. Since then, the production has expanded, there were bricks and blocks with different surface texture, coated with glaze based on glass or clay. Used manual molding products. The addition of plasticizers and modifiers made it possible to manufacture stones with increased frost resistance, resistance to ultraviolet radiation and other desired characteristics.

On our site you can find contacts of construction companies that offer the service of designing brick houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Decorative bricks are produced:

- Hollow or full-bodied. The first is used for the construction of fences, cladding facades, fireplaces, interior decoration. Cavities in the body of the stone increase the insulating properties, but reduce the strength. A solid brick is heavier, but it has a high bearing capacity and is capable of perceiving large stresses. Responsible loaded structures are constructed from it.

- In the form of a regular parallelepiped, a wedge, with beveled edges, rounded corners and edges. Due to its various forms, it is possible to lay out arches, cornices, columns, curved surfaces, to decorate openings and stairs.

- Standard dimensions 250x120x65 mm or other sizes. They depend on the purpose of the brick - basement, thin, angular. Facial decorative surfaces of spoon or knotty stones are located on one of the faces, the corner ones are processed on both sides.

The color palette is very diverse. When pigment is added, both traditional colors — red, brown, gray — and unusual colors — lemon, blue, khaki — are obtained.

Properties of torn brick

The finishing material combining decorative and protective functions has Properties:

- Off.

- Not rotting.

- Not damaged by insects, rodents.

- Environmentally friendly.

- Non-corrosive.

- Moistureproof.

- Durable.

- Temperature resistant.

- Does not fade, does not fade in the sun.

- Combines with smooth brick, plastic, wood, plaster, metal.

- Easy to install.

- Not demanding care.

- The price of imitation is several times lower than the natural material.

When building fences made of ragged stone blocks, you can efficiently use through voids by laying electrical wiring inside for calls, alarms, and lanterns in corrugated tubes.

Physical and mechanical properties, geometrical dimensions and marking of concrete stones are normalized by GOST 6133-99:

- Brand for compressive strength - 50-300.

- Frost resistance f 15-200.

- The maximum stone weight is 31 kg.

- The outer wall thickness in hollow bricks is at least 20 mm.

- Product designations according to the standard: s - wall, n - partition, l - facial, p - ordinary, corner - angular; ps - hollow.

- The marking indicates the brand of strength, frost resistance, thermal conductivity and density.

- Deviations of length and width of more than 3 mm from the norm, fatty spots, and surface defects are not allowed.

A special feature of torn brick is high density and large mass. One square meter of cladding weighs 140-260 kg. For finishing the facade or the construction of the fence requires a fairly powerful foundation. Reconstruction with the use of stone is recommended to combine with strengthening the base.

To reduce the weight of the fence, blocks for the fence "broken stone" are made in the form of a splitter - a large-sized hollow brick with notches at the ends.

Element dimensions - 390x190x90 or 390x190x190 mm. One splitter replaces 7-12 bricks, which allows you to quickly mount poles and fences. Often during the construction of a fence, light fillings of spans of wood, metal or plastic are attached to capital supports.

It might be interesting! In the article on the following link read about the brick pillar.

Facing the facade with a tattered brick

Finishing work with stone requires accuracy and skill. Vertical and horizontal seams should be flat, of equal thickness. Then laying looks spectacular and soundly. The textured surface of the brick must be protected from contamination. Get rid of them then very difficult.

The foundation of an existing house may not be strong enough and wide. To support a brick wall, a protrusion of at least 140 - 160 mm must remain. If there is no such platform, an additional reinforced concrete belt is prepared close to the base and attached with anchors to the main structure.

Before facing with a torn stone, the walls are prepared - clean, level, close up cracks. They must be sufficiently reliable to withstand the load of the brickwork. The lining is connected to a vertical surface with galvanized wire, rods or polymer elements.

A ventilation gap of 20-40 mm is left between the finish and the wall to avoid condensation. If this is not done, moisture during repeated freezing-thawing cycles will gradually destroy the building envelope, leading to the formation of damp stains and mold in the house.

To allow moisture to freely escape into the atmosphere, leave some empty vertical seams at the top and bottom or set masonry special perforated elements.

At the same time as finishing, walls are often insulated with extruded polystyrene foam or basalt wool. In this case, the width of the foundation must be at least the sum of the thickness of the brick, insulation and the size of the ventilation gap. Zoom will also have overhangs of the roof. Otherwise, the snow and rain, falling under the cladding of the building, will lead to dampness of the structures.

For the finishing of facades with a brick of torn stone, laying patterns are used:

- path - displacement of each subsequent row by 1/2 the length of a spoon;

- block - alternation of point and spoon rows with overlapping vertical seams;

- Bavarian — random mixing in a masonry of three or four colors;

- Dikarka — chaotic alternation in a series of tychkovy and spoon elements;

- Brandenburg - two spoon and one tychkovy row are sequentially shifted by 1/2 of the end.

The laying is carried out on cement-sand mortar 1: 3, a dye is added for expressiveness.

A fence made of bricks or blocks under a torn stone

The construction of a fence is no less responsible work than finishing the facade of a house. The fence anticipates the entrance zone, while protecting it from unwanted intruders. Neatly folded, with jointing in a contrasting color, it will decorate the site.

The foundation for the fence

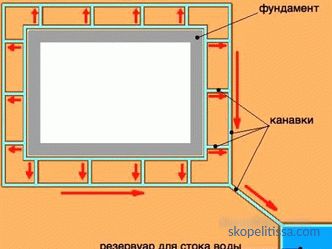

The construction of the fence begins with marking the area, clearing and building the foundation. If the fence will consist of capital supports and light fillings of the spans — a blockhouse, profiled sheet, polycarbonate, or a picket fence — the base may be columnar.

The recommended step for installing pillars is 3-3.5 meters. They dig pits with a depth of 70-110 cm, rubble 20 cm in thickness at the bottom. Such preparation will save the supporting structure of the fence from frost heaving and skewing.

In the pits, they assemble reinforcement cages of steel rods connected by wire. You can use a pipe or profile. The cores are strung hollow concrete blocks or brick. On the sides of the post leave embedded parts for mounting sheets of fencing.

A solid monolithic foundation is arranged under a fence made of bricks or blocks. At the bottom of a trench with a depth of 50-70 cm, a layer of 20 cm crushed stone is poured. The formwork is installed with an elevation of 20-30 cm above the ground level, reinforcement is laid, concrete is poured.

Masonry of torn brick

Masonry begins with the elements of the pillars, the rank and file customize along the length of the span. Control horizontality with a straight tensioned cord. For the stability of the structure binding of seams and fastening to the supports on the outlets of the reinforcement every three rows is obligatory. Hollows fill with a solution.

Bricklaying is conducted in half or a whole brick.

The block construction over four rows is strengthened vertically. To do this, steel rods are introduced into the center of the splitter.

Decorative jointing is performed using a slightly set solution.

At the end, the pillars are installed on the pillars. The laying is covered with water-repellent impregnation. It prevents the penetration of moisture into the concrete imitation.

Learn more about how to put a fence of torn brick, you can learn from this video:

It can be interesting! In the article on the following link read about the turnkey brick house.

Total

Torn brick is a spectacular finishing and construction material. With it, you can create a protective decorative covering of the facades, build a reliable fence, decorate the interior or landscape.