To maintain a comfortable microclimate, a country house is equipped with ventilation, especially if materials that are not breathable were used for the construction. This engineering system creates a comfortable living environment: it provides a constant supply of fresh air and removes unpleasant odors. Plastic air ducts for ventilation are a common solution. Such details have their differences, advantages and disadvantages.

Scope

Air ducts are used in the ventilation system. They provide an air channel through which gases are exchanged. Proceeding from SNiP 41-01-2003, plastic constructions can be used in ventilation in single-storey buildings - residential, as well as for public and administrative purposes.

But operation is strictly prohibited in:

-

basements;

-

attic rooms;

-

rooms for technical purposes;

-

in the territory of increased fire hazard .

Plastic pipes for ventilation is the optimal solution for country buildings. They are easy to install and, if necessary, can be ergonomically incorporated into the design of the room.

Design differences: shape, size, material

The most common and popular sizes of channels and pipes are as follows:

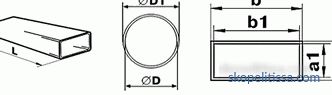

For round pipes:

| Name | Dimensions (mm) | Letter in the drawing |

| Internal diameter | 100; 125; 150; 200 | D |

| Length | 350; 500; 1000; 2000 | L |

For square:

| Name | Dimensions (mm) | Letter on the drawing |

| Height | 55; 60 | a |

| Width | 110; 122; 204 | b |

| Length | 350; 500; 1000 | L |

Additional designations D1, b1, a1 are indicated to display wall thickness. As a rule, they are 3-5 mm.

Material

The term "plastic" hides a group of polymers with different characteristics and properties. The most important indicator is the range of withstand temperature differences.

| Plastic | Temperature difference | Feature | |

| PVC | -30 | +70 | Cheap |

| PVDF | -40 | +140 | Good chemical resistance and fire resistance properties |

| PP | -20 | +120 | Insoluble by acids, alkali and does not react to organic |

| PND | 0 | +40 | High flexibility, protection against mechanical damage |

PP is excellent for kitchen hoods. The material is highly resistant to chemical damage and is easy to clean. If there is a heating element in the room (oven, batteries, etc.), then choose PVC or PVDF.

On our website you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

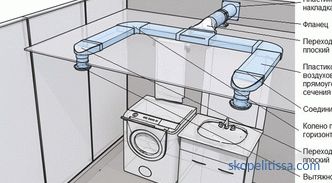

Ventilation elements

The complete construction consists of the following components:

-

air channel (round or rectangular);

-

connectors;

-

adapters;

-

knee (rotate 90 degrees);

-

splitters;

-

lining for walls (inserted into the wall and connected to the channel);

-

holders (for ceiling mounting);

-

protective gratings .

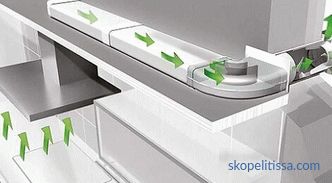

Plastic ventilation elements are assembled sequentially from small blocks into a single system. Binding places are insulated with a special compound, sometimes soldered. This is necessary in order not to disturb the air duct, any unplanned hole degrades the flow rate.

It might be interesting! In the article on the following link, read about supply and exhaust ventilation.

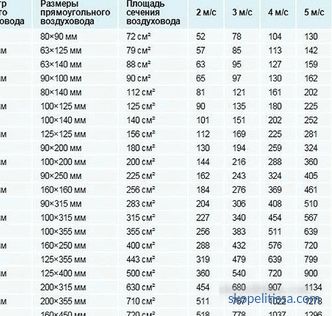

How the diameter is selected

When designing, engineers perform mathematical calculations and then compare all the values in the table. Below is a table comparing the parameters and speed of air flow.

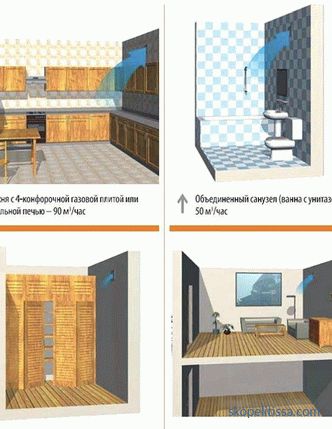

The duct diameter is determined based on the volume of the room or the performance of the overall system.The volume and rate of air circulation is controlled according to regulatory documents. The picture shows the air exchange rate for 1 family member for the premises of a private house.

The types and sizes of plastic ducts for ventilation are selected individually based on engineering calculations. It is important to consider system performance and airspeed. If it is exceeded, there will be a regular draft, otherwise there will be stagnation of air.

Which duct to choose: round or rectangular

Round pipes have better aerodynamic properties. But because of their shape, it is inconvenient to hang them and build them into the wall.

For this reason, plastic rectangular ventilation can be observed in most homes. Features of the form worsen aerodynamics, but it is more convenient to mount such channels under the ceiling or along the wall.

If aesthetics is not important in the room, use round parts. If ventilation is part of the design, it is preferable to use rectangular ducts. For the money goes about the same.

It might be interesting! In the article on the following link, read about ventilation in the house.

Advantages and disadvantages

In comparison with other materials, plastic products have the following advantages:

-

Low price .

-

Simplicity mounting.

-

Prefabricated structure with a butt system.

-

Good aerodynamic properties .

-

There is no hum (iron structures buzz a lot).

-

Do not rust .

Among the shortcomings it can be noted:

-

Flammability . When ignited, acrid smoke appears. The integrity of the structure is violated and harmful gases quickly spread throughout the room.

-

Electrification . Due to the constant movement of the plastic accumulates a static charge and attracts dust. This increases the level of fire hazard.

The main problem is the high risk of fire. Because of this, according to the requirements of SNiP, it is prohibited to install plastic ventilation in large buildings and subfloors. In the event of a fire, the plastic will melt and acrid smoke through the air ducts will spread throughout the premises.

It can be interesting! In the article on the following link, read about the ventilation of the boiler room.

Features of the

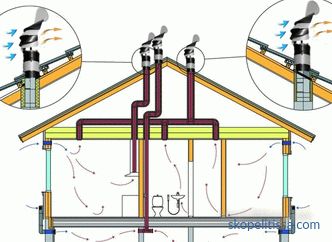

arrangement Regardless of the type of ventilation, it consists of two components:

-

The intake channel;

-

Exhaust pipe.

The task of the pipes is to ensure air circulation, which is carried out due to the pressure difference outside and inside the building, or by a fan.

Installation is carried out after drawing up a wiring plan for all rooms of the building. When calculating, it is important to take into account many factors: flow rate, system performance, movement of air masses, etc.

After accurate planning and calculations, the mounting of plastic ducts begins. This process is quite simple, but has a number of features:

-

Vertical (exhaust) pipes should not have horizontal branches . If they are created, they should be included in the calculation of the overall system performance.

-

Plastic parts should be hermetically sealed to each other . All slots are coated with sealant.

-

In difficult places , the use of corrugations is allowed. But often they are not recommended to use, as they have low aerodynamic properties. Corrugations are used without a stock, so that during the use the cross section is not changed (affects the total resistance).

-

Plastic parts are mounted after preliminary cleaning of the place from dust. All compounds are treated with an antistatic agent so that small particles do not clog up the free space.

-

When you purchase a material, you need to rely on some stock - of both the pipes themselves and the fasteners. It is very likely that during construction some sections will need to be further strengthened.

Features of the installation of plastic ventilation can be viewed in the video:

On our site you can find contacts of construction companies that offer services to the completion of unfinished houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Conclusion

Plastic air ducts are one of the options for creating ventilation in a building. The plastic is low cost and it is great for arranging a country house. But it must be remembered that it can not be used in the arrangement of basements and high-rise buildings.

Rate this article, we tried for you