Today we will talk about one very interesting finishing technology that is used for decorative facades. This is a house facing with stone panels. It is interesting because the panels themselves, though not a stone, are not distinguishable from the masonry in appearance. You will learn about the varieties of this finishing material and the technology of its installation on the front of the houses. Information will be useful to those who are going to use this material for facing their own homes. It will provide an opportunity to understand what and how they do the masters who were entrusted with this responsible work.

What are the panels

Facade panels for exterior decoration stone houses are classified as siding. Accordingly, the method of their installation is fastening on the batten (frame), which itself is attached to the facade of the building. That is, no wet processes associated with cement or adhesive solutions. This is the main distinguishing feature of the panels from the same stone, tile, clinker and other facing materials.

More recently, this material was called basement siding, because the original purpose of its production was to produce products that could be used to revet the basement part of the foundation (protruding above the ground). Over time, it turned out that the possibilities of ground siding are much wider. Someone from the masters just tried to lay it on the wall, since the decorative properties allowed to do this. The effect was unusual and original. And so it went, and the popularity of the material immediately increased significantly.

And the reason was the design of the panel, which is a stone or brick masonry. In this case, the stone can be any, because the forms of the product are formed on the standard masonry. That is, they assemble in the workshop on the floor a masonry of some natural stone, pour it with molding sand, which repeats its pattern. After drying, the form is removed and used for its intended purpose. The same with bricks.

As for the raw material for casting, the choice is huge, but acrylic, vinyl or propylene is more commonly used. Although some manufacturers today offer metal panels or fiber cement. The first are in the category of cheap materials, the second more expensive. But the quality of some panels from the first group of the second are not inferior. At the same time, the polymer material exactly repeats the pattern and structure of the stone; therefore, it is difficult to distinguish it from the natural stone finish in terms of realism even near the cladding.

And if we consider that the price component of the panels is several times smaller than that of a natural or even artificial stone, it becomes clear where such popularity comes from.

On our site you can familiarize yourself with the most popular sites in Moscow Region for building a country house. In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Today in the construction market it is possible to purchase panels for covering the house outside under a stone with imitations of such varieties :

-

granite ;

-

slate ;

-

stone stone ;

-

sandstone ;

-

dolomite ;

-

tuff and other stone rocks.

At the same time, manufacturers offer various color imitations of panel products, which expands the range offered by several times. That is, the model range of facing facade panels is so wide that it takes a lot of time to get acquainted and choose. And this greatly distinguishes them from traditional siding, whose variety of patterns and colors are not so rich.

Pros and cons of front panels under the stone

With some advantages panels for the facade of the house under the stone already familiarized, but their full list:

-

a huge range in terms of color and texture;

-

realistic imitated stone or brick;

-

small specific weight , which simplifies the installation process, and the panels do not overload the supporting structures of the building (this advantage does not apply to fiber cement products, they are quite heavy);

-

acceptable price (again, this does not apply to fiber-cement and metal products);

-

perfectly cope with all natural loads , even by the sun's rays, under the negative influence of which they do not change their color and do not warp;

-

panels do not rot , do not rust, do not take root on them harmful microorganisms;

-

simple installation ;

-

long-term operation - for at least 50 years;

-

simplicity of maintenance - it is enough just to pour water from a hose under a small pressure th.

On our site you can familiarize yourself with the most popular projects of houses for which panels were used under the stone, natural and artificial stone - from construction companies represented at the exhibition "Low-Rise Country".

And literally two deficiencies :

-

plastic panels become brittle at low temperatures;

-

when heated up in summer, expansion of products appears, so it is important to follow the installation instructions precisely and not to forget some of the nuances of the installation process.

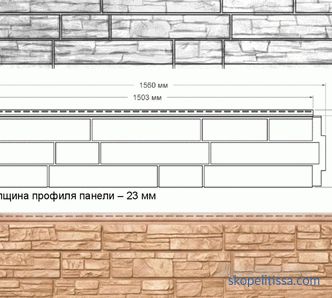

Dimensions and technical specifications

It should be noted that depending on the raw material and characteristics, and dimensional parameters will be different.

The length of plastic front panels varies in the range of 1-1.25 m. But there are elements of plating and up to 6 m on the market. The standard width is between 26-45 cm. The latter is more common. Thickness - 1-1.2 mm, in fiber cement from 6 to 12 mm. There are plastic with insulation layer up to 30 mm.

With regard to technical characteristics, the main is the temperature mode of operation, which is in the range of -40 ° C to + 60 ° C. All other characteristics, such as strength, moisture resistance, heat resistance and fire resistance depend on the material from which the panels are made.

Mounting technology

So, having sorted out the material for plating house outside under the stone, go to the method of its installation on the facade of the building.

On our website you can find contacts of construction companies that offer the service of warming and finishing houses, and use materials of their own production for this. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Installation of frame

It should be noted that some manufacturers offer panels for facade cladding with batten components in the set. This is convenient in that there is no need to select the material for the frame separately. Although the elements themselves are metal profiles. Therefore, if the lathing is not included in the scope of delivery, then the gypsum plasterboard profiles or wooden bars with a maximum section of 50x50 mm are used as its elements. Immediately we denote that the metal guides are in preference. They under the influence of changing humidity and temperature do not change their linear dimensions. What can be said about the wooden bars.

It is necessary to make a reservation that not all panels with imitation of stone are attached to the crate. Some of the models are attached to the wall of the house, if it is well aligned, or if a Penoplex-type insulation board is laid on top of it. In this cladding material, there are already mounting holes and mounting steps are the following :

-

panels apply at the attachment point;

-

through the holes on the wall make marks ;

-

remove panel;

-

on the marks > make holes in which plastic dowels are driven;

-

put facing material on the wall;

-

screw with his screws.

To help you understand how it all happens, watch the video:

This can be interesting! In the article on the following link, read about ways to trim a house with a stone.

But in this article, we are mainly interested in the cracking installation method. Therefore, in the first place its elements are mounted on the facade of the house. To do this, pre-mark up the installation sites galvanized profiles.Be sure to about the window and door openings, as well as at the edges of the wall. All other guides are installed in increments of 50-60 cm. By the way, the installation direction is vertical.

-

On the planned lines mount direct suspensions in increments of 50-60 cm. They are fixed to the wall with screws on plastic dowels.

-

Set the insulating layer . More often it is polystyrene foam plates or mineral wool in mats. Insulation directly put on direct suspensions.

-

vapor barrier is placed from the diffusion membrane. It is laid with stripes with overlap edges within 10-15 cm and with self-adhesive tape closure.

-

guide profiles are attached to the hangers, and they are fastened to them with self-tapping screws. The main task of the work producer is to set all profiles in a single vertical plane.

Installation and fastening of the front panel

The assembly process starts at the corner of the building, usually from the left. Gather panels in order. Fastening method:

-

for plastic models - self-tapping screws ;

-

for fiber cement - clamps .

In the first case, mounting holes have already been made directly in the cladding material. They are in the form of grooves, which makes it possible to adjust the exact docking of neighboring elements among themselves.

It might be interesting! In the article follow this link read about the front stone.

Here is the algorithm of the assembly operations:

-

first set and fixed to the crate the starting level , which is strictly horizontal,

-

below the corner element , it must be set exactly, because the installation starts from it;

-

then it is inserted into the corner panel and into the start panel the bar is the ordinary panel , which is fixed along the profiles laid with screws;

It is very important to set this row horizontally. Further, in the same sequence, the remaining rows are collected to the upper edge of the wall. Please note that in the vertical direction, the cladding elements are assembled with the help of a locking groove-tongue joint, which ensures complete parallelism of the rows between each other and one hundred percent tightness of the joint, which is very important for facade materials. The edges of the top row are closed with a so-called J-bar. In fact, this is the finishing bar, which gives the butt completeness of design.

An important step in the finishing of houses outside under stone is facing of the areas around the openings (windows and doors) . Lining panels made of plastic or cement - a material that is well treatable. To cut it to the required size is not a problem. To do this, use the grinder or stationary cutting machine. Therefore, around the openings of the panel is laid with cropping to the desired value (height or length). The installation itself is made according to standard technology. After completion of the work, the open ends are closed with special corners or slopes that complete the decorative design of the facade of the building.

For how to install front panels from the manufacturer Döcke-R, see the following video:

And in this video, examples of decorating houses with artificial stone:

It might be interesting! In the article at the following link, read about the gray color in the home decoration: yes or no.

Conclusion on the topic

Panel covering of a house under a stone is one of the effective ways to make the building presentable, solid and unusual, which stands out from everything that construction companies can offer today. We add that this type of cladding is a pleasure inexpensive, but with a sufficiently long service life. That is, in many respects it surpasses other materials and technologies.