Laying heat-insulating materials under the exterior of the house significantly reduces heat loss, and hence the heating bill. In addition, if you know how to properly warm the house under the siding, then you can additionally expect to improve the sound insulation of the walls.

Insulation under siding: types of insulation

Choosing insulation, take into account several indicators :

-

material of which the walls are made;

-

weather conditions;

-

characteristics of the isolator;

-

financial side of the issue.

Not always the cheapest material is the worst.

Manufacturers produce insulation designed for different wall materials, operating conditions:

-

mineral wool;

-

foam;

-

polystyrene foam;

-

polyurethane foam;

-

extruded polystyrene foam;

-

glass wool.

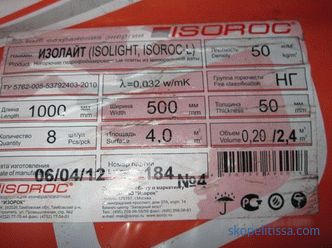

When calculating the amount of insulation, take into account the thickness of the material, the number of layers of the coating.

Basic requirements for insulation for siding

Main The requirement for an insulator is low thermal conductivity. The smaller this figure, the more heat is retained in the building. Mineral wool and extruded polystyrene in addition to low thermal conductivity have good sound insulation properties.

When choosing a material for home insulation, pay attention to:

-

moisture resistance;

-

susceptibility to fungal infection;

-

resistance to temperature changes;

-

durability;

-

fire hazard;

-

environmental friendliness.

Some types of insulation for the walls of the house outside under the siding are mounted with special membranes that absorb moisture.

The advantages and disadvantages of materials

-

The benefits of mineral wool include low cost. It has a low thermal conductivity, good sound insulation performance, but is not resistant to moisture, is easily flammable. To protect the material from wetting, fluid-absorbing membranes are additionally installed.

Wool in rolls is more often used on horizontal surfaces, as it poorly protects the joining places and has to be laid in 2 layers. Wool in slabs has a more dense structure, so it covers walls in 1 layer.

-

Foam has a porous structure . This material is filled with gas bubbles. It retains heat well. Manufacturers produce plates of various thicknesses. You can select the material based on the need. It has a low cost, lightweight, easy to install. The main disadvantage is that it is spoiled by rodents. It conducts air poorly, so a room with such a heater can accumulate moisture. In addition, the foam has a short lifespan - 12-15 years, burns and at the same time releases toxic substances.

On our site you can find contacts of construction companies that offer the service insulation of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Polystyrene warm the foundations of buildings. The material is well resistant to moisture, poorly conducts heat. The main disadvantage is the high cost. Therefore, the use of material limit the foundation of the house.

-

Polyurethane (PUF) has a liquid structure, low thermal conductivity, resistant to moisture, mold, rodents. The material is applied with special equipment. Good noise insulator. Application in liquid form allows you to cover the surface without joining seams. Disadvantages is poor UV resistance. You must have the skills to work with the technique for applying to the surface

-

Extruded polystyrene foam resistant to moisture, mold, retains heat well. Big minus - poor resistance to fire.

-

Glass wool is stable fire, easy, easy to install, cheap. This is one of the most popular materials. The disadvantage is the need for special protection of the person during the installation of the material.

It can be interesting! In the article on the following link, read about siding block house.

How to insulate a wall of a house under a siding

Coating various walls requires “its” insulating material. An improperly selected insulator is able to make the room wet, some of them have a short lifespan.

Brick house

For this type of wall, the best option is basalt insulation (a type of mineral wool) or polystyrene foam. The material is simply mounted, cheap, has good insulating qualities.

PE foam has good thermal conductivity, but you need to invite specialists to install this material.

Foam is lightweight, easy to use, cheap. This is the most popular insulation.

Warming up the foundation of the house under siding is best done with expanded polystyrene. This material is most resistant to moisture, has a dense structure.

House of foam blocks and aerated concrete

Aerated concrete walls have a high vapor permeability. With the wrong choice of heat insulator, the wall can mold, start to rot. Insulation should not violate the gas exchange between the house and the environment.

Mineral wool is used on this surface. It has a high vapor conductivity and in combination with aerated concrete will keep the microclimate in the room.

Polyurethane foam showed itself well on such walls. If you spray this material on the surface, you can avoid the joints. This will reduce heat loss.

Do not install polystyrene and polystyrene foam on the walls of aerated concrete and foam blocks. They have poor vapor permeability.

Wooden houses

Wood has a low thermal conductivity, but is not resistant to fires , moisture, insects. Choosing which insulation is better for the walls of a wooden house outside under the siding, they consider that it must eliminate these disadvantages. The best choice for wood is PPU. It is lightweight, retains heat well.

For a wooden house, fiberglass and mineral wool impregnated with special fire-resistant compounds are used.

It might be interesting! In the article on the following link read about siding under stone.

Surface preparation for installation of insulation

Before installation of insulation, the wall is cleaned of layers of cement and water leaks. The gap must be sealed with a special compound. Nails, pins cut off. A smooth surface is covered with an antifungal mixture and allowed to absorb.

The technology of home insulation under the siding

There are 3 types of installation of the insulator - sticking rolled materials on the surface and fixation on the frame:

-

In the first case, glue is applied to the wall, covered with insulation. Left for time to set. Fixed layer crate.

-

The frame method is convenient for plates. This material is more rigid, fixing on the wall is carried out with screws, nails, glue.

Before installing the units, check the level. First set the profile on which the plates are placed.

The installation direction is selected by the wizard. It is more convenient for one to install the blocks, moving from the corner to the center, the other is easier to start from the center of the surface. It does not matter. The main thing is the quality of installation.

-

The third way to install insulation under siding for a wooden house is to install on a cross-frame.

Experts consider this method to be the most successful, although its cost is more expensive. The principle of the method is that at first a heater is installed in the frame in the horizontal direction. Then they put a crate on it, and an insulator on it in a vertical direction. This method of installation allows you to minimize heat loss.

If you plan to cover the membrane, it must be applied from the bottom up. Fixation of cloths is carried out by a construction stapler. The fastener spacing is 20 cm. The material is placed with an overlap of 10 cm in. For complete insulation, the joining points are sealed with tape.

Clearly about the cross-warming of a frame house, see the video:

Tips when installing insulation

-

If vinyl siding is planned to be installed, galvanized screws and nails should be used. This will protect the metal from rust and the construction will last longer.

-

When choosing mineral wool, you should ask whether it is treated with a fire protection mixture.

-

The joints of the insulator blocks must be sealed to avoid moisture.

-

If you plan to use mineral wool, it is better to install blocks on a vertical surface. They have a more dense structure, therefore, have better insulating properties.

-

Membranes are laid on foam plastic and mineral wool. If you do not do this, condensation will accumulate in the house. The additional ventilation gap creates a crate.

-

Places around windows and doorways require additional fixing of insulation. Also stubbornly fix the insulator at the corners of the building.

-

For installation thermal insulation does not require alignment of the walls.

-

The calculated amount of material should be increased by 5 - 7%, as part will have to be cut during installation.

-

To fix the insulator, use the dowels with dish-shaped caps. For each block use at least 5 dowels.

When choosing how to warm the frame house under the siding, take into account the ability of the material to conduct moisture. Among consumers is popular mineral wool. It is cheap, easy to apply to the surface. Masters advise to insulate such buildings with the help of PPU.

How much does it cost to sheathe a house with siding

The cost of home insulation depends on several components:

-

material prices;

-

wall sizes;

-

insulation consumption;

-

use of additional materials (membranes, fasteners, surface pretreatment);

-

the cost of the work of the master (the higher the qualification of a specialist, the more expensive you have to pay).

Different manufacturers set their price on insulators. The cheapest is foam.

Since there are a lot of variables to determine the price, it is difficult to give an exact figure, even knowing the area of the walls that will be insulated. The price can vary from 200 to 800 rubles and more per square meter and any specialist will call the final cost only after having inspected the house and taken measurements. The average cost of home insulation is 43,500 rubles.

About the insulation of the house with polyurethane foam and the cost of the work, see the video:

It can be interesting! In the article on read the following link about the crate under the siding.

To insulate or not

To insulate a building under siding is a necessary step. Despite the fact that the cost of changing the facade of the house at the same time increase, this measure pays for itself in saving on heat carriers. The correct choice of heat insulator will reduce heating costs by 30-40%.