The subject of the article is the ridge for the roof made of sheeting. In it, we will consider how this element of an iron roof is formed, what is used to close it, what materials are used for this, installation rules and other equally important aspects. I would like to immediately indicate that not all roof structures have a horse. So, it is not always necessary to deal with it and solve the problem posed by the article.

What is the ridge of the roof

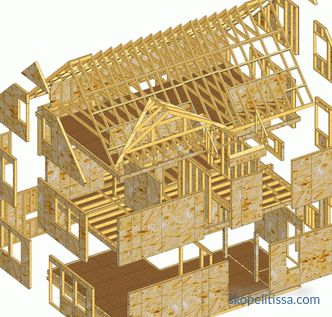

This element is obtained at the junction of two ramps. In this joint must form a line, which is called the ridge. For example, at the hip roof of this element is not, although the slopes are joined at one point. But not all joints are so called, but only the upper and outer ones. For example, the inner corner formed by the two slopes, called endovoy.

As for the professional flooring, laid on the sloping roof, then according to the technology of its laying the sheets should not fit along the ridge close to each other. Be sure to leave a free gap through which the air from under the roofing material comes out. But so that precipitation does not fall into this gap, it is covered with a special additional element, which is called the ridge bar. Although purely constructively the ridge is part of the roof, not a separate detail of the roofing. But in everyday life, even the masters call this bar skate. Therefore, we will speak about it: what it is made of, what form, and what size.

Types of a ridge for professional flooring

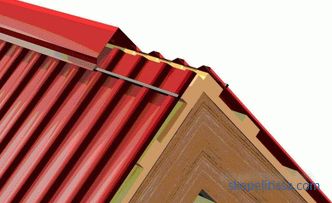

To begin with, the ridge on the roof of profiled sheeting is made of the same material as the profiled sheets themselves. That is, from galvanized steel sheet, painted or coated with a polymer layer. In this case, the ridge plate is selected in the color of the roofing.

Now, as for the shape of the product. Here are three options: corner, rounded and U-shaped.

The first one is a detail in the form of a corner with seamed edges. The easiest option, without claiming high aesthetic forms, but also the cheapest, because the technology for their production is bending the galvanized strip to the desired angle.

The second is a more aesthetic form in the form of a gutter with fastening racks, with edges curved. These models form a large volume vent pocket. In addition, these ridge strap must be closed from the sides with plugs. With a high aesthetics of rounded skates, their price is also high, of course, in comparison with other options.

The third option is the most interesting from the standpoint of the decorative design of the roof. But its production takes a lot of metal, plus shaped caps, in a coupe, the high price of the product.

As for the size of the skates on the roof of corrugated, the length varies in the range of 2-3 m. But the width determines the angle of inclination of the slopes, so in this regard, the range is wide.

On our site you can familiarize yourself with the most popular sites in Moscow Region for building a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Technology of installation of the ridge plate

To begin with, the flooring is a profiled material. That is, its shape is a wave of a rounded or trapezoidal shape. The horse mounted on them provides absolute ventilation. It adjoins the mounting shelves to the upper waves of the roofing material, and is attached to them, and through the space formed by the planes of the lower waves and the ridge shelf, air escapes from under the roofing surface.

But this free space is a place where dust, insects, small birds, garbage and other troubles fly under the roof. Today, this problem is solved by installing a special sealing material between the ridge plate and corrugated sheet. In fact, it is a tape of porous material, which, when compressed, forms a dense protective barrier.

Types of compactors for the ridge

Manufacturers today offer several types of compactors for skates made from different materials.

-

Polyurethane foam seal . This is a universal material with open porosity with a long service life. In the presented model line there is a self-adhesive version, which increases the ease of installation of the tape on the profiled sheets.

-

Polyethylene . This is a figure-type seal that exactly follows the shape of the profiles. Material tight and tight with closed pores. In it for ventilation leave openings. But they can be kept in the closed state if aerators are installed on the roof: pitched or ridged.

-

Tape PSUL .This is a self-expanding seal made on the basis of acrylic and polyurethane. On sale in compressed form. After the installation of the ridge, it expands, completely filling the space between the roofing material and the ridge. By the way, the material is expanded 5 times from its original state.

Please note that almost all seals completely cover the gap between the ridge strip and the roofing material. Therefore, in most cases, the ventilation of the ridge of the roof under the corrugation is organized through the side openings, which are closed by perforated plugs. Often, even the plugs do not install.

It might be interesting! In the article the following link read about ridge price on the roof of corrugated board: types of skates .

Rules for the installation of the ridge plate

The installation of the ridge of the roof from corrugated boarding begins with the choice of the type of ridge strip. Then you need to decide on the number of purchased items. Everything is simple here. It is required to know the length of the ridge girder, which is divided by the length of the plank. Be sure to take into account the fact that between the elements are mounted with an overlap equal to 15-20 cm. That is, the number of joints will increase the length of the span. Therefore, they do it simply, buy another element to the estimated quantity.

I would like to pay attention to two points concerning the formation of a ridge girder:

-

The edges of the profiled sheets should not close the ridge girder. The distance from the edge of the laid sheets to the top of the roof is 5-10 cm.

-

The continuous crate of the two that lie next to each other must be laid under the top edges of the roofing material boards. The bottom line is that the mount of the ridge on the roof of corrugated board is not produced in the roofing material, but in the crate.

And one more equally important point. The line of intersection of the slopes should be flat. The error is allowed, but not more than 2% of the width of the mounting shelf. For example, if the installation of a ridge rail with a length of 2 m and a width of 20 cm mounting shelves is planned, the deviation from the line of intersection of the slopes should not exceed:

20x2% = 20x0.02 = 0.4 cm.

If this parameter does not meet the required standards, then the probability that the roof will leak at the place where the ridge is installed , will be quite high. This problem is solved in two ways:

-

The most difficult is to shift the roofing material.

-

The simplest is to choose a ridge bar with a greater width of the mounting shelves.

Installation of the slats starts from any edge of the roof. First put the seal. Two methods are used here:

-

glue the sealant on the back surfaces of the mounting shelves;

-

glue to the roofing material .

The first option is simpler and more convenient to perform.

Lay the first bar. It is attached to the crate through the upper corrugations corrugated roofing screws. The fasteners are screwed every 30-40 cm with an indent from the edges of the shelves within 2-3 cm. Then the second one is mounted with overlapping edges. The mount is exactly the same. And so all the other elements.

Pay attention to the correct selection of the length of the fastener, because the twisting is produced in the upper wave. Usually this parameter consists of the wave height of the profiled sheet and the thickness of the batten.

The video shows the sequence of installation of the ridge rail on the roof covered with corrugated flooring:

It might be interesting! In the article on the following link read about a birdhouse in a Canadian forest .

Conclusion on the topic

So, we have dealt with the device of the ridge of the roofing board. We decided on the forms of the ridge plate and the method of its installation. In fact, this element is included in the category of the “most important additional elements” of the roof structure. Without it, the roof will be just unfinished.