Projects and prices of houses from a profiled bar is one of the leaders in viewing on the websites of construction companies. They are more expensive than “skeletons” or log houses from a conventional bar, but they are significantly cheaper than projects of glued timber of the same size and complexity. In addition, a house of profiled timber is assembled at the facility in a short period of time (from several days to two months), so it is easy to explain the popularity of this particular material for suburban housing for permanent or seasonal residence.

This is how a modern house from a bar for a large family looks like

Features and advantages of a profiled bar

Profiled beam Compared with the usual - the same "step forward" in the development of wooden housing, as the rounded log in relation to the usual. Therefore, its advantages are similar:

-

it is completely ready planed lumber that does not need to be improved;

-

the walls are assembled due to the factory carved connecting profiles and locks;

-

wood treatment with protective compounds (antiseptics and fire retardants) at the production stage of the timber.

The reliability of the connection of elements can be strengthened with a modern stainless steel spring assembly

But compared to a cylindrical log the profiled bar has advantages:

-

"smooth" front surfaces simplify additional wall insulation;

-

tighter junction of the locks improves the insulation of the interlayer and corner connections;

-

a wall of uniform thickness does not have weak nodes that are “cold bridges”.

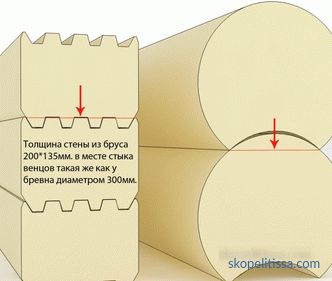

This scheme clearly demonstrates the advantages of a profiled bar over a rounded log

In terms of volume, for achieving the same indicators of energy saving, profiled timber for exterior walls will require up to 40% less than a rounded log.

In addition, a bar, unlike a log, can be forced dried. This significantly reduces the already small shrinkage value, bringing it in this parameter to the laminated timber. If you bring these figures to an absolute value for walls 3 m high (during the year), they look like this:

-

rounded log - up to 10 cm;

-

edged timber - up to 6 cm;

-

profiled timber of natural humidity - up to 4 cm;

-

dry profiled timber - up to 2 . 5 cm;

-

glued laminated timber - no more than 2 cm.

Profiling also contributes to partial compensation of internal stress forces, which reduces the number and size cracks in the wood as it dries.

In some cases, additional process cuts are even made, due to which cracking occurs in a given plane

Of course, the glued bar has no cracks in general, but it costs 3-4 times more expensive. Although this is not its only drawback - there are two more:

-

Glued laminated timber differs in environmental safety classes. And even the highest of them (E1) means that there is a certain level of fumes that are not very useful for humans (formaldehyde emission).

-

The presence of longitudinal layers of glue reduces to almost zero the natural gas exchange with the street at the "molecular level" inherent in ordinary wood.

Therefore, despite all the advantages, the main quality of wooden houses is not at the walls of laminated veneer lumber - perfect environmental friendliness and breathable properties.

The design features of houses from a profiled bar are that all its bearing elements and partitions are completely manufactured in the workshop, and then assembled on the prepared foundation in accordance with the design documentation. In contrast to wooden houses and wooden houses made of brick or concrete blocks, the construction process is put on an industrial basis, that is, much of the work on the creation of the "box" takes place at the factory. Therefore, the construction time of the profiled timber for the customer is so small - he simply does not see the preparation of building materials for installation.

Ready-made kit for the walls of the house, where each element is numbered in accordance with the project documentation

On our site you can find out more popular projects of houses from the profiled timber from construction companies represented at the exhibition of houses "Low-Rise Country".

Project or design

Most construction-related companies provide a full range of services. And the simplest of them is to buy a finished project. And here are possible options.

For example, the architectural bureau offers a documentation kit without reference to the terrain.And the cost of such a package of documents, which is actually called a “project,” depends on the area, number of floors, and architectural features of the building.

So a “simple” garden house with one bedroom and an area of up to 50 m² can be estimated at 5-6 thousand rubles. , and the project of a large two-story house with an attic, 3-4 bedrooms, balconies and a garage can cost you more than 30 thousand rubles.

An example of a typical project of a house from a profiled bar

And for a fee, specialists will conduct:

-

geological surveys and select the type of foundation;

-

work out the options for arranging utilities, autonomous water supply and sewage;

-

develop an architectural passport and agree a ready-made package in the appropriate instances;

-

they will develop a design project for the interior;

-

the landscape design and the general layout of the site with all types of buildings (from the fence to gazebos);

-

will accompany the construction as field supervision.

What is the convenience of this approach - a short time to get the finished package of documents without modifications (depends only on the speed of delivery) and the possibility of obtaining such a service anywhere in the country. The client can only find a contractor in his region.

Computer visualization of the project gives a complete picture of the exterior of the house

On our site you can find contacts of construction companies that offer construction services houses from profiled timber. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

If it is necessary to refine the finished project according to the recommendations of the customer, then the most inexpensive adjustment that does not affect the layout and facade may cost at least 100 rubles. for 1 m2. If we are talking about changing the layout or architectural appearance of the facade, then this figure should be doubled.

And the most expensive option is the development of an individual project of a house from a profiled bar. The production of such a documentation package includes several stages:

-

Sketch design. Development of architecture and house plan with dimensions. The choice of floors and roofs, colors. Floor cuts indicating the height of the premises.

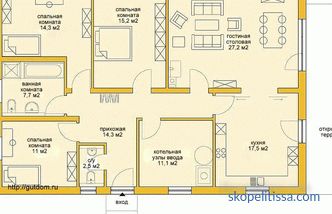

Plan of a one-storey three-bedroom house

-

Architectural and construction project. Detailing on structures and assemblies, calculation of materials.

-

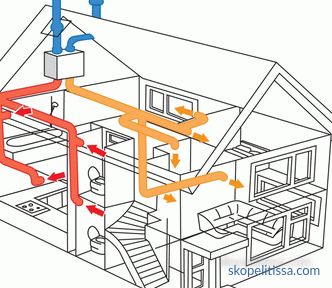

Engineering project. Development of communication schemes, the choice of components and equipment.

And the cost of an individual project will be much higher than the finished one - from 700 to 1000 rubles per m2.

As a result, the optimal solution is to choose a company with a full cycle of work and buy a house from a profiled bar, the project of which either fully satisfies the customer or requires minor modifications.

In most cases, the company makes such changes in the documentation for free - it does not take a lot of time, since the entire database is stored in electronic form, and the correction takes place automatically after the project is amended.

About the nuances of choosing a construction company for building a house on a turnkey basis, see the video:

Prices

The price of 1 square. meters of finished log houses "starts" from 8 thousand rubles. and may be higher than 15 thousand rubles. There are several factors that directly affect the cost of construction:

-

The profiled timber can be natural moisture and dry. Drying of such a large volume of wood usually takes place in special chambers and has a different technology. The most advanced methods include the manufacture of compensatory sawing (so that the bar does not crack), the treatment with saturated steam under pressure (to displace the natural moisture from the pores) and the smooth change in temperature conditions until the bar reaches a humidity of 16-20%. Therefore, the chamber drying beam is 10-20% more expensive than usual.

During chamber drying, additional production cycles are added to the bar manufacturing technology

This may be interesting! In the article on the following link read about the log house from a bar.

-

Wood species. Cedar dry timber is on average 20% more expensive than pine, and larch prices are up another 10%. And if we compare the timber of dry larch and pine of natural moisture, the price of 1 m3 will be at least twice as different.

-

Architecture and number of storeys. The simpler the construction and decor of the house from the turnkey profiled beam, the lower the complexity and cost. The number of floors is the opposite. With other things being equal, a square meter of a two-story house will be cheaper than a single-story one — the roof, the foundation and the engineering systems are common, and in terms of "specific weight" in the price they occupy a smaller part.And if you compare two houses with the same usable area, then a two-storey one will be cheaper than a single-storey one.

For beautiful and practical projects of houses from a profiled bar, see the video:

-

View of the foundation. Heavy foundations (slab or full profile tape) can take up to 25% of the total cost of building the "box" - the base, walls, ceilings and roof. For "light houses" made of wood, if you do not plan to build a basement or an underground garage, you can restrict yourself with a pile or shallow strip foundation. And for a guest or garden house to choose an even cheaper option - a columnar foundation.

Combined foundation - for the house there is a ribbon, for the terrace and porch brick pillars

Installation steps

The most common type of construction of houses from a profiled bar is the so-called basic equipment for "shrinkage" or "heat circuit". Therefore, focusing on the price proposals laid out in the catalogs, we must bear in mind that this does not include work, without which the house is not suitable for housing - for example, interior decoration and wall insulation. They must be ordered separately.

Construction "under shrinkage" of wooden houses from a profiled bar of natural moisture looks like this:

-

Laying the foundation. This stage most of all affects the duration of the construction of a log house. If the project requires the arrangement of a slab or ribbon, it will take 4 weeks for concrete to mature. In addition, excavation, sand-gravel cushion preparation, installation of formwork, reinforcement, pouring, stripping, waterproofing, and insulation will be required.

-

Assembly of the box and installation of the ceiling. This includes the delivery of "domokomplekt", installation of the bottom trim and the overlap of the first floor, the construction of walls and partitions, the installation of the top trim and interfloor overlap.

-

Arranging the truss system and mounting the batten. Work on the insulation of the roof, hydro and vapor insulation insulation. Installation of the roof and additional elements.

House for shrinkage

It might be interesting! In the article on The following link read about siding under the bar.

"Thermal circuit" also includes the installation of windows and doors, therefore this type of work is possible only for the construction of dry profiled or glued timber.

If the project in the catalog is listed as “turnkey”, then the house should already be completely finished, have internal wiring and connections for all engineering systems — that is, be ready for installation. And in these cases, as in the construction, options are possible from the basic "economy class" to the development of an individual design project. And taking into account the cost of a separate study of interiors, prices for finishing materials, insulation, costs for climatic equipment and other additional expenses that each company stipulates separately, the total price per square meter can increase several times.

The advantage of a timber house is that there is no need for wall decoration

Where you can save

It is the construction division of a house on two stages "under shrinkage" (or "thermal circuit") and "turnkey" gives the opportunity to save.

Naturally, the savings during the construction phase of the box should be "reasonable". For example, you can choose a pile rather than a strip foundation, paying more attention to the insulation of the ground and the ground floor floor. Choosing a project, you should pay attention to the houses of the timber section 150x150 mm. According to the new standards of thermal protection of buildings, the walls of a wooden house, if they are not 50 cm thick, must be insulated. And the difference with a bar of 200 or 220 mm width is easily compensated by mineral wool in the curtain wall.

Exterior insulation of a wooden house with mineral wool will make it truly warm in the Russian winter

And the main "reserve" of savings is this is finishing work. And the easiest way is to choose materials of domestic production. Moreover, the majority of our trademarks are manufactured on the equipment of leading world manufacturers.

It might be interesting! In the article on the following link read about the house from the turnkey bar.

Conclusion

With all the advantages of a profiled bar, there is an item of expenditure during construction that cannot be saved on: the quality of materials and the qualifications of the performers. Wood material is "moody" and does not tolerate negligence either during processing or during installation.