Well-being and high performance largely depend on the purity and freshness of the air in the room. Regular airing is often not able to provide an optimal microclimate - in this case, fresh air ventilation is installed. The system is installed not only inside the premises, but also in kitchens, lounges and smoking rooms.

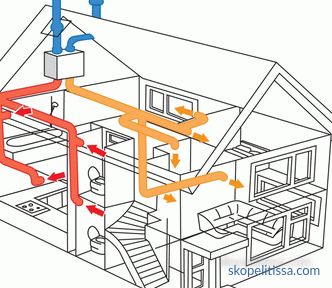

Schematic diagram of supply and exhaust ventilation

Physical basis of ventilation

Air movement flows based on the simplest physical processes. Processing of the gas-air mass and its transportation is carried out thanks to the existing convection processes. To use this natural process, sources of heat and heat are placed in the lowest areas, and the inlet elements, on the contrary, are as close as possible to the ceiling.

In general terms, the term "convection" is a redistribution of heat energy between heated and cold gas flows. Convection processes can occur in a natural way, or by force.

In a closed space, the total temperature is determined by the degree of air heating. The value is not constant in the whole space, varies in height. The phenomenon is due to inhomogeneous concentration of molecules with constant pressure inside the room. At higher temperatures, the concentration of gas particles is less, which means that its mass is less. Therefore, there is the notion that the heated air is “lighter” and the cold “heavier.” This fact explains the structure of the ventilation systems: the exhaust units are located on the top, and the supply units - on the bottom.

Air movement usually takes place from the bottom up

Properly designed exhaust ventilation system combined with natural convection processes allows you to maintain a set level of temperature and humidity indoors.

What is a ventilation system

In a general sense, a ventilation system is the movement of air between an external environment and an enclosed space. From the heated and stuffy room, the air mass carries excess heat, moisture, which leads the indoor climate in line with sanitary and hygienic requirements. The ventilation system can be part of the interior design of the room and is part of the general communications network of the building.

Air masses are driven by a special ventilation system, including a set of process equipment, cleaning filters. Its main tasks: the collection, withdrawal, movement and air purification.

The main difference between ventilation and air conditioning is the controlled full cycle of updating air masses by inflow and outlet. Whereas air conditioners only heat or cool the air, they increase humidity and ionization.

A normal air conditioner simply drives the room’s air in a circle the spread of viruses, fungi, increase humidity to the recommended level. In case of emergency, ventilation allows you to quickly replace indoor air with a piping system, fans, heaters, filters.

Varieties of ventilation systems

All ventilation systems can be divided into several types according to different criteria.

Depending on the pressure generation method, the following ventilation systems are distinguished:

-

Artificial. The movement of air occurs with the participation of the installation of discharge: blowers, fans. With increasing pressure inside the pipes, the air masses can be moved over long distances. Most often used in central ventilation systems.

-

Natural. It occurs where the movement of air flows occurs naturally due to the difference in temperature and air pressure at different ends of the pipes. The advantages of such a system for residential premises include low installation costs, no need for special equipment. But in such systems it is impossible to predict the work or manage them, so they are often used as auxiliary.

Scheme of natural and artificial ventilation

On our site you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Combined. The most commonly used type of ventilation, combining the advantages of artificial and natural systems.

According to the impact area, the following varieties are distinguished:

-

General Exchange. It has a wide area of exposure, for example, all rooms of a residential building.Through the ventilation shafts, exhaust air is discharged from the interior, where the concentration of negative substances is low and they are evenly distributed.

-

Local. An air duct is supplied to certain places, which draws out harmful discharges and leads them to the outside. It is mounted indoors where the release of harmful substances into the air occurs pointwise. In residential buildings, this is most often a kitchen, in particular, a kitchen stove. The construction of the local network is cheaper than the general exchange, but it is designed for less air flow.

Depending on the operation scheme, inlet, exhaust and intake-exhaust systems are distinguished. Exhaust structures are intended only for removal of polluted air. The intake ventilation system provides fresh air masses. Systems where air is drawn and injected are the most popular.

For supply ventilation in the walls air ducts are punched

Supply and exhaust ventilation ensures optimum maintenance in various rooms destination and scope.

Depending on the technical device of the system, the following are distinguished:

-

The modular systems of the folding type include various modules: heater, noise muffler, fan, filter elements, automatic control unit, auxiliary units. The advantage of modular designs is the possibility of selecting nodes with the necessary characteristics. The disadvantages are complex installation with the involvement of specialists.

-

Monoblock are ready-made kits in a single unit. The design is easy to install, does not require complex maintenance and care. The cost of monoblock systems is higher than modular.

The presence of several types of ventilation allows you to select and install the most suitable to specific conditions.

Features of natural exhaust ventilation

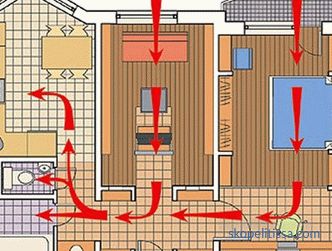

Unlike designs with artificial generation, natural ventilation systems use the existing air flow from the living rooms to the kitchen and bathroom. Movement occurs through the corridors, which act as flowing spaces. It is possible to equip such ventilation even inside houses with non-standard planning.

General air movement does not change

The main ventilation unit is placed on the upper central part of the house. When laying pipes take into account that clean air must flow into the living room, and be discharged through utility rooms and kitchen. Supply air ducts are located on the border of living rooms, and exhaust elements inside the utility room, bathroom, kitchen.

Diffusers (outer part of the duct) are made of plastic, thin sheet metal. They serve as a distributor of clean air and the withdrawal of waste. The external exit of the pipeline is placed higher than the roof is arranged. This prevents the secondary collection of waste mass.

It might be interesting! In the article on the following link read about pipes for ventilation.

Features of forced ventilation of the exhaust air

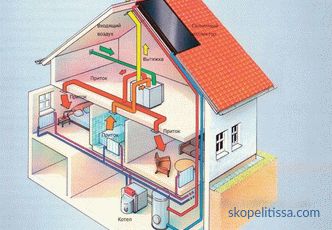

The operation of this system is based on the interaction with two different air streams, which are conducted through the installed air ducts. Depending on the power and throughput of the mechanisms involved, a given volume of air masses is processed.

All working units and equipment are located inside a single building, which can be assembled in any convenient place: on the outer wall, attic, or attic.

The supply and exhaust ventilation unit installed in the attic

Depending on the optional equipment, exhaust ventilation can perform the following functions:

-

increasing the humidity;

-

saturation with ions;

-

cooling or heating of the air mass;

-

purification, filtration, elimination of harmful microorganisms.

The modern intake-exhaust ventilation system as part of the module has a heat exchanger - a heat exchange chamber, where the occurring air flows exchange energy. Heat is removed from the heated exhaust air and released to the incoming air (or vice versa, if an air conditioner is operating in the room in summer).

Principle of operation of the heat exchanger

The work cycle of the ventilation with two circuits and the heat exchanger consists of the following steps:

-

warm air from the room is conducted through the heat exchanger, heating the heat exchanger installed in it;

-

the "exhaust" air is removed to the outside;

-

clean cool air is taken from the outside and is conducted through the heated heat exchanger of the heat exchanger, extracting heat from it;

-

fresh heated air is fed into the room.

To expand the functionality, the design is complemented by filter systems, automatic timers, control units, condensate collection trays, control units, sensors, noise suppressors.

Inflow ventilation with automation system

It might be interesting! In the article on the following link, read about the ventilation of the under-roof space.

The main principles of this type of ventilation is efficiency and effectiveness. The main advantages include:

-

simple installation and maintenance of supply and exhaust ventilation;

-

high-quality cleaning of the input air masses;

-

block integrity;

-

design modularity.

Main parameters of the ventilation system

The main working element is the fan, but not the usual propeller, and the impeller, which is a wheel with blades - this design reduces the size of the equipment .

The operating efficiency of the assembled structure directly depends on the accuracy and correctness of the preliminary calculations. For example, equally bad if insufficient or excessive engine power is selected. In the first case, the engine will run to wear and soon it will have to be changed. If the power is redundant, then this means regularly increased costs for maintenance and payment of electricity.

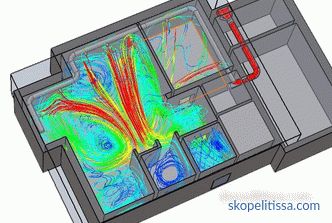

Calculations of the performance and dynamic parameters of air flow are made by algebraic formulas. It is recommended that you entrust the calculations to a specialist who not only does this correctly, will receive the necessary approvals from the fire inspection.

The operation of supply and exhaust ventilation is checked by firemen

When calculating, the following data is taken into account:

-

Room parameters: the purpose is residential or non-residential, internal area, number of floors, humidity level.

-

The number and type of activity of people who are simultaneously inside the building.

-

Required level of air exchange according to SNiP 2. 04. 05-91. For example, in living rooms it is 3 cubic meters per 1 meter of living space per hour.

-

Section of the pipeline and its installation.

What are the standards for ventilation systems

The recommended air exchange parameters depend on various conditions and are spelled out in the relevant regulations that are necessarily taken into account when designing. In general, for domestic premises, when rooms for different purposes are concentrated on one floor, such an amount of air should change in an hour:

-

study - 60 cubic meters;

-

common living rooms or halls - 40 cubic meters;

-

corridors - 10 cubes;

-

bathrooms and showers - 70 cubic meters;

-

smoking rooms - over 100 cubes.

In living rooms, the exchange of air mass is calculated per person. At one o'clock it should be more than 30 cubes. If the calculation is made on the basis of living space, then the standard is 3 cubes per meter.

For non-residential premises, the average standard is 20 cubic meters per square meter. If the area is large, then the ventilation systems include a multicomponent system of twin fans.

Obviously about the standards for ventilation, see the video:

What formulas are used in the calculations

The main parameter that needs to be calculated in any system is how much air should be changed within an hour.

For residential apartments, the value is determined respectively by the living area: V = 2xSxH, where S is the area of the living room, 2 is the ratio of the multiplicity of exchange of air mass for 1 hour, H is the height of the room.

For workplaces, the calculation is made based on the number of personnel: V = Nx35, where N is the number of people who are simultaneously in the room.

In calculating the power of the ventilation station, the following formula is used: P = ΔT * V * Сv / 1000, where V is the volume of air mass consumed per hour, Cv is the heat capacity of air mass, ΔT is the temperature difference of the air mass at the ends of the pipeline . The accepted value of heat capacity is 0.336 W * h / m³ * ° C.

Another important indicator is the duct cross-sectional area, measured in square centimeters. There are 2 types of section: square and rounded. Having calculated the cross-sectional area, it is possible to determine the width and height of a rectangular pipe or the diameter of a round one.

More about the calculation of ventilation in the video:

Ssech = V * 2.8 / w, where Ssech is the cross-sectional area, V is the volume of air mass (m³ / h), w is the speed of the air flow inside the main (m / s) (average value from 2 to 3), 2.8 is the coefficient of matching the dimensions.

For installation, it is necessary to calculate how many diffusers (intake and exhaust) are required and their parameters.The nozzles dimensions are calculated based on the cross-sectional area of the main pipeline multiplied by 1.5 or 2. To calculate the number of diffusers, the formula is used: N = V / (2820 * W * d2), where V is the air mass volume consumed per hour, W - the speed of movement of air mass, D is the diameter of the circular diffuser.

For rectangular diffusers, the formula is converted as follows: N = π * V / (2820 * W * 4 * A * B), π is the number of pi, A and B are the section parameters.

In any case, the calculations of the ventilation systems should be carried out by professionals - if something is forgotten or not taken into account, the cost of the mistake is the need to redo the calculations and work.

A full calculation of the intake ventilation is done on specific software

It can be interesting! In the article on the following link read about ventilation in the house.

Conclusion

The installation of a supply and exhaust type ventilation structure will help to maintain an optimal indoor climate. This increases the efficiency of people living in the house and simply improves their well-being. Particularly relevant is the question of ventilation for owners of modern homes with hermetically closing windows and doors, because along with getting rid of drafts, natural air exchange also disappears. In such houses, it is advisable to provide a fresh exhaust ventilation system at the design stage.