It is believed that the profiled sheet was invented by Henry Palmer, who designed the first British railway. This engineer in the 20s of the 19th century pointed out the advantages of light containers made from special metal sheets. The novelty was appreciated by builders, and since then the professional sheet has become widespread in the construction of walls, roofs and fences. Roof decking has established itself as a reliable and functional material that allows to obtain high-quality roofing.

Types and technical characteristics

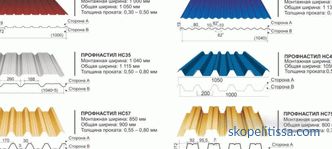

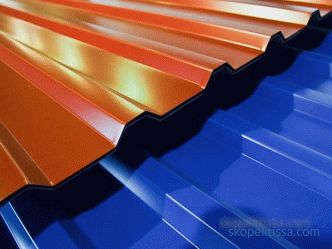

The profiled sheet (professional sheet, corrugated sheet) is cold-rolled metal sheet with a complex profile. Among other types of sheet, intended for roofing, can be distinguished by the presence of a capillary groove (groove, pressed on the edge of the sheet and helps to wipe off moisture). Marking of such material begins with the index НС, ПК or R, the number after the index indicates the height of the wave. Roofing decking has the following set of characteristics:

-

Material . Sheets are made of steel, can have only double-sided galvanized coating and an additional, protective and decorative. The operational properties are affected by both the thickness of the sheet and the thickness of the zinc layer. There are expensive options made of chromium-nickel steel, aluminum or copper.

-

Thickness . For a low profile, a minimum thickness of 0.4 mm is allowed, for a high profile - at least 0.7 mm.

-

Structure . Profiled - composite (multilayer) material. Different brands number of layers varies from 3 to 10; thickness can also be different.

t70000-02

t70000-02

-

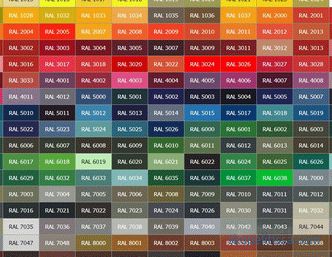

Coverage type . The coating has a protective and decorative function, it can be polymeric or paint and varnish and have several layers. The warranty provided by the manufacturer depends on the number and thickness of the coating layers. The most common polymer coating (color, matte or glossy) is acrylic, polyester, polyurethane, polyvinyl chloride.

-

Additional Coverage . On some types of professional sheet, additional film is applied (lamination is carried out). Additional protection against mechanical damage increases the price (sometimes by 8-10%), but is considered necessary for complex polymer coatings.

-

Type of the ridge (corrugations, waves). Products with a wavy or trapezoidal (European norm) profile are produced. The professional sheet for a roof has height of a wave from 20 to 100 mm; comb and wall can be strengthened.

-

Additional elements . These include components used for the design of the roof nodes: end and curtain strips covering the eaves, edges and joints of two slopes; ridge, protecting the point of convergence of skates.

On our site you can find contacts of construction companies that offer roof repair services . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Geometrical dimensions and weight

The maximum length of the profiled sheet is limited to the technological capabilities of the production and is 12 m. Usually, manufacturers cut such a workpiece multiple of 1 m or 0.5 m; accuracy depends on the quality of the equipment. The calculation of the required amount of material is carried out taking into account the transverse overlap of individual sheets. The size of the longitudinal overlap depends on the angle of inclination of the roof - the smaller the angle (below the ramp), the more this parameter is set (for an angle of 15 ° the overlap is 20 cm). The width of the side overlap is half the width of the wave.

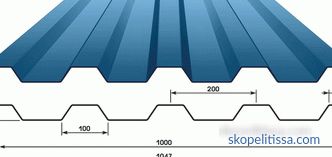

Manufacturers indicate two sheet widths - overall (standard, total) and useful (working, assembly). Overall width is the initial parameter of the sheet (from 1 to 1.25 m), the useful width is that obtained after the formation of a wave, it is always slightly smaller and depends on the height of the wave.

It is important to understand that when selling a material, calculations are made using the total width. But the builders, when they count the roofing for professional roofing, operate (which is quite natural) with the concept of working width. To calculate the useful width, the size of the overlap (the width of a single wave) is subtracted from the total width.

The thickness of roofing sheets from 0.45 to 1.2 mm is regulated by GOST 24045-2010 and, despite the seeming insignificance, it is quite sufficient for the construction of a strong roof. The profiling procedure gives the sheet additional strength (rigidity). Builders move on the laid sheets, without deforming them, due to the complex shape of the profile, redistributing the load.

The weight of a sheet is derived from its dimensions: length, width, and thickness.The weight between the corrugated roofing is also influenced by the distance between the waves and the structure of the protective and decorative coating.

Advantages

The successful combination of performance characteristics makes the flooring one of the most used roofing materials. The following parameters are among its advantages:

-

Durability . The warranty on various types of material can reach 20-25 years; Term depends on the thickness and type of polymer coating. By the life of the roofing sheet is comparable to bitumen and metal tiles (warranty on slate is 15 years).

-

Available cost . Excellent value for money contributes to the popularity of sheeting for the arrangement of the roof. Material cheaper bitumen and metal.

-

Durability (reliability). Due to the profile, the material easily withstands significant mechanical and snow loads.

-

Corrosion Resistance . Thanks to layers of zinc, primer and polymers, the sheet is protected from the damaging effects of moisture.

-

Low weight . The roof does not exert significant pressure on the supporting structures. Also transport and installation is much easier.

-

Resistance to natural phenomena . The material is resistant to temperature extremes, solar ultraviolet and atmospheric moisture.

-

Fire Safety .

-

Range of design solutions . Polymeric coatings make it possible to produce sheets in a wide color palette, comparable to the palette of metal tiles and superior to other roofing materials.

-

Minimum care . Metal profile during operation does not need regular maintenance.

It might be interesting! In the article on the following link read about repairing the roof of a private house.

Disadvantages of a professional sheet and ways of minimizing them

Despite a solid list of positive qualities, the roofing corrugated board also has disadvantages that are identified during operation. Understanding the material's weaknesses makes it possible to reduce their influence at the stage of the roof installation. The disadvantages of a professional sheet are its following features:

-

Low sound insulation . The insignificant thickness of the metal sheet leads to the appearance of a drum effect - an increase in sound during rain. Someone likes to fall asleep under the noise of falling drops, and someone slowly begins to get annoyed by the monotonous fraction. In order not to experience discomfort during each, even a small rain (and in some edges a lot happens), a proven method is used - strengthening the roofing pie with an additional layer of sound insulation. The role of the insulating layer is most often performed by mineral wool with a parallel effect of warming.

About how to choose the right flooring in the following video:

-

Loss of corrosion resistance . If the protective layer of the professional sheet was damaged during transportation or installation, the corrosion process will most likely begin. They are trying to stop it by staining the damaged area, which is not always effective and almost always unaesthetic. In order to prevent the appearance of corrosion, it is worth buying material from reputable manufacturers. Their products are protected from accidental damage by individual packaging and gets to the construction site without scratches and chips. Equally important in the fight against corrosion is properly carried out (according to the instructions) installation. The result of the advice of some sites about the ease of self-installation are numerous foci of corrosion in places of non-professional mounting.

-

Violation of the roof tightness . It is rather not a feature of the material, but the low professionalism of the roofers. In order for the roof to be moisture resistant, a set of measures is needed: a sufficient size of the overlap of the joints, a high-quality sealant treatment of the seams and attachment points on the screws.

-

Overheating of the attic space . Rescues from it high-quality roofing pie with a sufficient layer of insulation.

It might be interesting! In the article on the following link read about the roof for the roof.

Factors affecting the cost of corrugated

The cost of core roofing material consists of three components: the thickness of the metal, the type of protective coating and the shape of the profile.

1. Thickness

A company that produces a professional flooring buys raw materials - rolled steel with polymer coating. The metal from which the profile is rolled may be of Russian, Finnish, English, Chinese origin.Raw materials can be of different thickness, with different zinc content and with a coating of different types. The country of origin, of course, affects the cost of the roll, but the determining component of the price is the technical parameters, the main of which is thickness.

Rolled stock is purchased by weight. It follows from this that of two rolls with the same weight, but with different thickness of rolled products, you can stamp a different number of professional sheets. The thinner the rolled stock, the longer the roll and the more finished products at the exit; therefore, the price for corrugated roofing depends mainly on the thickness (the difference in price between sheets of the same type with a thickness of 0.7 and 0.4 mm reaches 50%).

About the intricacies of choosing a professional flooring in the following video:

2. Sheeting

The professional roofing sheet is divided into several price categories depending on the type of corrosion protection:

-

Galvanized profiled . The most budget and therefore popular option. For the roof, try to choose a galvanized metal profile of maximum thickness and with a high zinc content. But it is not recommended for installation of the roof of a residential house, because the material without a protective layer does not tolerate temperature and humidity drops; This affects the service life is not the best way.

-

Paintwork . A thin layer of varnish and paint provides reliable protection against corrosion; if necessary, it is easy to update.

-

Plastizol . A common polymer coating resistant to mechanical, chemical and natural factors. Plastisol does not like sudden temperature changes and direct sunlight, from which it begins to fade.

-

Polyester . The most budget profiled covered with polyester; the difference in price with similar sheets (of equal thickness and profile, but with a different protective layer) is 30%. Polyester coating is quite reliable and durable; Matt coated sheet is especially advantageous.

-

Coverage Pural (Pural and Pural Matt). It is a more resistant coating suitable for use in areas located close to motorways. It easily withstands temperature fluctuations, exposure to moisture and ultraviolet radiation.

-

PVDF Coating (Polydifluorionad, PVDF). One of the best options for roofing corrugated. The coating reliably protects against all weather surprises of the Russian climate, as well as from scratches and chips; It can be used near motorways and industrial sites. Sheets coated with PVDF can boast one of the most interesting colors (with metallic shades).

3. Profile shape

Profile shape also affects pricing. The higher the profile height, the smaller the width of the finished sheet will be and the more such sheets will be required for your roof. On the other hand, with an increase in the height and thickness of the corrugations (stiffeners), the strength of the material increases, and, therefore, the ability of the finished structure to withstand the load.

About what influences the price of corrugated flooring in the following video:

Not only the roof profile is used for the installation of the roof: certain wall grades are often used (C20, C35) or carrier (H60, H75); The final choice depends on the needs of the customer.

It might be interesting! In the article on the following link read about the flat roof in a private house.

.

Profiled flooring

The choice of roofing corrugated only at a price can lead to a sad result - the sheet will not be suitable for your specific conditions (for example, for an area with snowy winters). Before buying it is worth exploring the offers of different manufacturers and the characteristics of the products offered; Specialist advice will not be out of place. If you choose the right profiled sheet parameters, after installation, you can forget about the roof for several decades.

Many manufacturers develop a so-called price matrix to facilitate the selection - detailed tables with indicating the type of material and the main technical characteristics (thickness, profile height, type of coating). Many resources offer and calculation of corrugated roofing (both on the online calculator and on site). The price for some types of professional sheet (with an average overall and useful width) in Moscow and the region is as follows:

-

Professional sheet C8 (polyester, 8 mm profile height): from 185-190 rub. / m 2 .

-

Sheet C20 (polyester, profile 20 mm): from 190-195 rub. / m 2 .

-

Sheet MP18 (zinc, 18 mm profile): from 207 rub. / m 2 .

-

Sheet C21 (polyester, profile 21 mm): from 212 rub. / m 2 .

-

Sheet C44 (zinc, profile 44 mm): from 269 rub. / m 2 .

-

Corrugated roofing C8 Norman MP: from 345 rub. / m 2 .

-

C21 Grand Line Optima Satin 0.5 mm (brown-red): from 450 rub. / m 2 .

-

C21 Grand Line Optima Zn 0.7 mm (galvanized): from 499 rub. / m 2 .

-

C21 Grand Line Optima Pe 0.7 mm (graphite gray): from 602 rub. / m 2 .

It might be interesting! In the article on the following link read about the posts for the fence of corrugated board.

Conclusion

The use of profiled sheeting makes it possible to equip the roof of a country house in a short time. Knowledge of the features and basic parameters of the material allows you to make an informed choice, the result of which will be a beautiful roof with high performance characteristics.