In the article we will talk about what constitutes a transparent roof. What materials it is constructed from. Let us analyze the technology of construction, as well as denote the nuances of the installation process, affecting the quality of the final result. After reading the article, you will receive complete information about this roofing structure, which means you will understand what and how do the masters, who have entrusted the roofing work.

Materials for a transparent roof

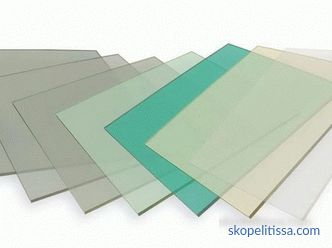

Let's start with the materials, because There is not much market, but the construction budget depends on the choice. Among the townsfolk and craftsmen, one term is used when the conversation leads to transparent roofs. This is the so-called plexiglass. In terms of transparency, this sheet material is not inferior to ordinary quartz glass, but in terms of its structure it is a polymer.

The plexiglass category includes a small model range of different materials, differing from each other in raw material content. These are sheets of transparent polyvinyl chloride (PVC), polystyrene, polycarbonate and acrylic.

Acrylic glass

Most often this material is meant by plexiglass. It is often called plexiglass or polymethylacrylate. As for its characteristics, by weight it is less than twice that of ordinary glass. It has good strength properties, good elasticity and excellent translucency, which does not yield to silicate glass.

This is a sheet material with a thickness that varies in the range of 1-25 mm. A wide model line for this size allows you to pick up acrylic plexiglass for any roofing structure, even in the form of arches. Manufacturers have the ability to tint the material, giving it any color shades. At the same time panels with a smooth surface and corrugated are offered. The latter option is often used in decorative glazing.

What is acrylic glass, the answer to the video

Polycarbonate

We must pay tribute to the fact that today polycarbonate is again very popular. All experts consider it as the best option for a transparent roof for a terrace, a greenhouse, a roof over a porch and other roofing structures.

The reason for such popularity is not only high transparency, elasticity and durability, an important characteristic is resistance to breaking. It is 150-200 times higher than that of silicate glass. To all it is necessary to add that cellular polycarbonate is an excellent insulating material. For this characteristic, it will not yield to glass packs.

The advantages of polycarbonate still need to be added to high operational safety, reasonable price, reduced complexity of working with it, and the presentable appearance of any glazed structure in which it is used.

On our site you can find contacts of construction companies that offer design and execution services all types of roofing work - any complexity and turnkey. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

It is believed that polycarbonate should not be installed on greenhouses. Say, it has a negative effect on plants. But not everyone understands that polycarbonate is restrained only by ultraviolet rays, passing infrared through itself. It is the last type of sunlight required for plants. In addition, the long-term operation of this transparent material in greenhouses and greenhouses refutes the fact of poor development of green plantings. So it can be safely used in these buildings.

But, when praising polycarbonate, we must take into account that it has some drawbacks:

-

it does not stand up , like silicate glass, to abrasive impact;

-

a large coefficient of thermal expansion , and this must be taken into account when constructing a polycarbonate transparent roof covering.

Transparent PVC and polystyrene

There are two types polyvinyl chloride: in the form of a film with a thickness of 500-750 microns and in the form of slate. The purpose of the first is to close the vertical openings instead of windows. Therefore, such a film is often called soft windows. Due to the cheapness of the material, it is used to cover homemade greenhouses along with other polymer films. At the same time, the strength of polyvinyl chloride is several times higher. She calmly withstands a blow brick. Yes, and the service life depending on the thickness varies from 5 to 10 years. But on the roofs for terraces, verandas, gazebos and other buildings, PVC film is not used.

A transparent slate is used for this. This material is actually produced in the form of a wavy sheet, hence the comparison with asbestos slate. In addition, it is transparent.The mounting method is exactly the same as the standard slate material.

Polystyrene glass is a sheet material. To make you understand what is at stake, think of disposable tableware of a transparent type. Part of it is made of polystyrene. The sheets themselves are produced in two different sizes: 1 or 2 m long and 1.5 to 3.5 m wide. Most often, this material is installed as a roofing structure in greenhouses, greenhouses and greenhouses. But rarely used for roofs or roofs, it is just more expensive than the same polycarbonate.

It might be interesting! In the article on the following link, read about how to choose a roof for a country house.

Roofs made of silicate glass

Do not forget that ordinary transparent glass made of silicate did not lose its demand. Today, thanks to innovative developments in the field of construction, the opportunity has appeared to construct transparent roofing structures. And this applies not only to sheds. Glass roofs are very popular today.

Manufacturers offer two types of them:

-

based on the technology of plastic or aluminum windows;

-

on the basis of thick sheet glass, the so-called panoramic glazing .

The first option is the simplest of the two and the most exhausted to little things. In fact, these are windows in glass frames, which are interconnected in a roofing glazing construction. The main task of the manufacturer is to accurately measure the future of the roof and accurately collect all the elements among themselves. A small discrepancy can lead to inconsistencies in the joints of individual elements.

But such a roofing structure also has its advantages. For example, the ability to construct roofs of any configuration and complexity. Presentable appearance, giving lightness and freshness to the architecture of the house. Even a small glass canopy near the house distinguishes it with its openwork and originality.

Sheet coating is thick glass that is arranged in frames that form the roof. This technology has come to the country building from the architecture of swimming pools and shopping centers. In fact, these are all the same windows, only larger ones. Aluminum and plastic profiles are also used as a frame material; some manufacturers offer steel profiles. The main requirement for such structures is the strength and reliability of the frame.

It might be interesting! In the article on the following link read about the nuances and prices of arrangement of a turnkey roof

Disadvantages of silicate glass roofs

There are a lot of minuses in roofs of this type:

-

high thermal conductivity , therefore in summer under such roofs hot, cold in winter;

-

constant mechanical cleaning of glass surfaces from dust, water stains and dirt is required, in winter it is obligatory from snow;

-

as a waterproofing material between the structural elements, silicone sealant is used, which under the influence of natural loads quickly loses its waterproofing quality , therefore the roof it is necessary to monitor for sealing;

-

you should not build large glass roofs, if the slope of the slope is less than 30 °, there is water stagnation from rain and melting snow ;

-

high cost of the structure compared to polymer coatings.

Innovative glass roof

On the market recently appeared transparent roof tiles. This material got its name because it is made of silicate glass, in form resembles metal roofing. That is, these are small sized elements of a wave shape. The structure of the material itself is double, where air is left between the layers. This gives the material such useful properties:

-

increases heat-insulating qualities of tiles;

-

gives it the properties to work, as a lens, focusing the sun's rays.

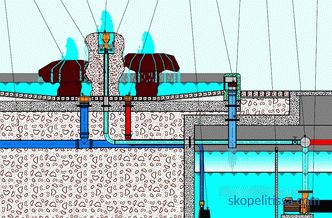

The last characteristic is very important - it is this property of the transparent material that pushed the creators to begin its release. Under the roof install tanks filled with water, as well as heating elements. They under the action of focused sunlight quickly heat up. Thus, using the energy of the sun, solved the problem of heating and hot water. True, transparent tile is quite expensive.

It might be interesting! In the article on the following link read about soft roof prices Katepal.

The construction of a polycarbonate roof

For example, consider the technology of building a transparent roof for a polycarbonate veranda. We assume that the roof system is ready, it remains only to lay the roofing material itself.

Immediately make a reservation that polycarbonate sheets are produced with a length of 6 or 12 m. This is convenient in the sense that you can choose the size so that less waste remains. To connect the sheets using a special profile, in which there are grooves on both sides. In them sheets for the roof and inserted. Manufacturers offer two types of connecting profile :

-

solid;

-

collapsible, consisting of two parts: the lower one is laid under polycarbonate sheets, the second is installed on top and pressed to the roofing material with screws.

The polycarbonate package includes another profile - the end profile. It is installed on the ends of the panels to close them tightly. The connecting profile is produced with a length of 3 m, but the end profile is 2.1 m. To fix the polycarbonate panels, special screws with thermal washers and caps are used to close the fastener heads. The latter give presentability to the appearance of the junction of sheets, besides, they are represented on the market by a wide variety of color shades. Please note that fasteners are sold separately from the sheets.

Here is the sequence of installation operations:

-

On crate stack connecting profile.

-

A polycarbonate sheet is inserted into it with one edge .

-

On the other hand second sheet .

-

If you use a profile of the collapsible type , then install a cover (top of the product) on top of it, which is attached to the bottom with self-tapping screws.

-

Thus, collect all the roofing material.

-

Install end profiles along the lower and upper edge of the panels.

How to mount polycarbonate panels to the frame is shown in the following video:

It can be interesting ! In the article on the following link read about the transparent house - not only boldly, but also beautiful.

Conclusion on the topic

Summing up the topic of the article, it is necessary to say that the transparent roofing construction is slowly conquering the space of suburban construction. This is actually an interesting option that has diversified the architecture in the suburban areas. But do not sing only the praises of such roofs. They have serious shortcomings, one of which is rapid pollution. So the roof of transparent materials will have to constantly clean.