The warm roof is a hot topic today, because heat loss through it is 20%. The market of building materials offers a huge range of heaters, and in this article we will analyze one of them - Penoplex. We will talk about the very insulating material, its technical characteristics, the technology of insulation of the roofs of the penoplex, and also pay attention to some of the nuances of the process of insulation of roofing structures.

What is Penoplex

To begin with, Penoplex - This is not the name of the material, and the brand. Insulation itself belongs to the category of polystyrene plates produced by extrusion. That is, the foam mass of polystyrene is passed through a special apparatus, which is called an extruder. The mass of the polymer is subjected to pressure, eventually it turns out very dense, but light material. In it, polystyrene is only 2%, the rest is air bubbles.

Since this material is a heater, one of the most important requirements for it is to have a low thermal conductivity coefficient, that is, the ability to pass heat through it. Depending on the density of the manufactured product, which is from 25 to 50 kg / m³, the thermal conductivity will be different: from 0.028 to 0.035 W / m K. The dependence is such that the denser the penlex, the higher its thermal conductivity.

There are also a couple of characteristics that determine its properties:

-

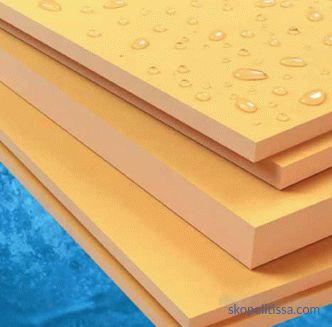

moisture absorption per day - 0.4%, an excellent indicator, that is, the material is practically does not absorb moisture;

-

temperature range operation from -50С to + 75С;

-

fire safety class G3, that is, penoplex well burns and maintains pressure, although today manufacturers offer Penoplex-35, treated with flame retardant compounds.

The last characteristic creates a lot of controversy about whether to use insulation of this type for thermal insulation of roof structures. After all, today the question of using non-combustible materials is increasingly being raised. If you follow the innovations, then first of all you will have to abandon the wooden truss system used everywhere. Most likely, it is necessary to follow other requirements, namely the requirement of fire safety of buildings and structures. Adhere to these simple rules and regulations, and you are not afraid of any fires.

Roof insulation technology with Penoplex

So, we will have to consider two types of roofing structures: pitched and flat. Warming of roofs by Penoplex of these two types is carried out differently.

How to insulate a flat roof

First, it should be noted that a flat roof is usually formed by reinforced concrete floor slabs or a solid reinforced slab. It is rare when it is constructed from floor beams. But sometimes there are situations in which it is necessary to warm flat roofs covered with roofing material. Here we have in mind not a roll coating, but from corrugated flooring.

In any case, the order of work in the described situations is the same. And it consists of the following:

-

The flat roof first check for defects and flaws that are immediately repaired. Usually use a cement-sand mortar or bitumen mastic.

-

The roof plane cleans from debris and dust.

-

If the roof is concrete, then it must be treated with a primer or a bituminous primer.

-

Spend assembling of the Penoplex plates. This should be told in more detail.

To begin with, the heater is laid either in one or in two layers. But the method of attachment they have the same - on the adhesive composition. For this you can use:

-

liquid nails ;

-

bitumen mastic ;

-

dry glue mixtures ;

-

polyurethane glue in a barrel .

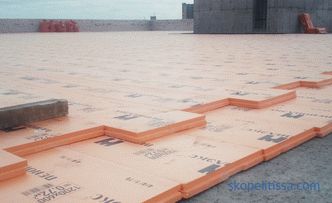

For flat roofs covered with a bitumen primer, the best option is mastic based on modified bitumen. It is applied on the plates themselves: along the perimeter and diagonal, after which the insulation is simply applied to the surface of the flat roof at the destination.

On our site you can familiarize yourself with the most suburban home construction sites in the Moscow region . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

There is one subtle point here. Penoplex plates are two varieties, differing from each other in the shape of the ends. The first - with straight ends, the second with a groove or with a facet. So that you understand what is the second option, look at the photo below. It clearly shows how adjacent plates are interconnected.It is important to understand that the strength of the connection does not depend on the shape of the joint, it ensures tightness. Strength provides glue that is applied to the plane of chamfers. For this it is better to use polyurethane adhesive composition.

That is, this method provides a seamless coating. Plates with straight ends are also used in the process of roof insulation. They are laid tightly to each other, trying not to leave cracks and gaps. If such all the same after laying the insulation formed, then fill out a special foam sealant. It is very similar to mounting foam, only in air it does not increase in volume.

Two-layer insulation of the roof with polystyrene foam is exactly the same process. Only insulation is laid in two layers. There is one moment that cannot be overlooked. Plates of heat-insulating material in different layers should be laid offset to half of the panel. That is, the seams between the plates of Penoplex in the first layer should fall on the middle of the insulation boards in the second layer. In this case, it is recommended that the heat-insulating material of the first layer additionally fix the dowel-nails: two for one plate.

It can be interesting! Read the following link in the article about roof repair in Moscow: prices for roof repair .

So, the heater is laid. It remains to close it with a waterproofing membrane. Lay waterproofing strips with an overlap of 10-15 cm. The joints of the bands must be closed with self-adhesive tape. After that, a concrete screed with a slope of 1-5 ° is poured over the insulation cake. And already on it after drying lay the roll roof.

Warming of pitched roofs

It should be noted that pitched roofs are primarily a truss system, in which rafters most often are boards with a thickness of 30-50 mm and a width of 100-200 mm . Wood itself is not a bad heat insulator, so warming off rafter legs is not necessary. But the distance between them should be insulated first. How is this process carried out?

Everything will depend on whether a new roof is being insulated, uncovered with roofing material, or operated. In principle, the technology in two cases is the same. That is, to insulate the roof from the inside (penoplex or other insulating material).

Let's consider the thermal insulation process if the roof is not covered yet.

-

The steam insulation films are laid over the truss legs . Lay out its stripes from the eaves in the direction of the skate. In this case, the lower edge of the upper band should cover the upper edge of the lower band by 10-15 cm.

-

The rails that form the counter-lattice fit along the rafter legs (along) . Its purpose is to create a gap for ventilation of the roofing space.

-

Mount the crate .

-

Roofing material is laid and fixed.

All other processes related to roof insulation are transferred to the attic or to the attic. Here the plates of the penoplex are laid between the rafter legs. The mounting step of the latter is specially chosen so that the plate in width between the rafters enters the tension, tightly pressing against the lateral ends of the rafter legs. This is so as not to leave gaps through which cold air will begin to penetrate under the roof in winter.

But it should be noted that the width of the insulation slab leaves 60 cm. Not all roof structures have such a step of installing rafters. If it is larger, the plates are laid across, that is, in length, while cutting each panel to the required size. For information, we add that the length of the Penoplex panels is also standard: either 1.2 m or 2.4 m.

It may be interesting! In the article on the following link read about the cost of roof insulation work from the inside of the mineral wool - price per m² in Moscow .

Now, as for the thickness of the insulating material. Manufacturers offer several options of this size: 20, 30, 40, 50, 60 and 100 mm. They select plates in such a way that they fill the space across the width of the rafter legs. For example, if the width of the used rafters is 150 mm, then one can use a single layer of plates with a thickness of 100 mm and a second one with a thickness of 50 mm for roof insulation using foam plastic (we mean Penoplex). The options may be different, but you should not increase the number of layers to the maximum.

So Penoplex is installed. It remains to close it from the inside of the attic with a waterproofing film. In principle, this can not be done, because Penoplex plates have excellent moisture resistance.They do not absorb moisture, which rises from the interior of the building in the form of wet vapor. By the way, the latter easily pass through the concrete floor.

In the video, the specialist talks about how to properly insulate the roof with polystyrene foam plates:

If the roof is non-residential, then the truss system is sheathed from the inside with slabs or sheet materials, used, or unedged boards. If the roof is part of the attic construction, then the plating is carried out with gypsum plasterboard, clapboard, plywood, chipboard and OSB. Choose any. It is clear that the trim is subsequently covered with a finishing finish.

And the second option - the roof is in operation. That is, it is covered with roofing material. From the inside of the attic, she is all the same rafter legs. In principle, the technology of insulation is the same, but there is one nuance. The vapor barrier is placed on top of the rafters from the inside of the attic, as shown in the photo below. That is, the film wraps the rafters, to which it is attached, but creates a cellular form of the truss system, leaving room for the insulation.

It might be interesting! In the article on the following link read about insulation of the facade of a private house: necessity, choice of materials, facing .

How to insulate a sloping roof on a truss system

Such a situation occurs rarely. The reasons may be - replacing the roofing material, reducing the insulating qualities of the previously installed insulation, there is no possibility to carry out additional repairs to the attic room. What you need to do for this:

-

roofing is being dismantled.

-

The lath and counter grille are dismantled.

-

For the truss system they assemble a continuous crate from OSB or boards.

-

The are used to mount Penoplex plates with gluing and mushroom-shaped self-tapping screws (dowel-nails).

-

The sheathing elements (slats or boards) are laid on the heat-insulating layer and fastened to the OSB with long screws. Here it is necessary to take into account the thickness of the batten, insulation and OSB board. All these materials screw must go through.

-

The roofing material is mounted on the batten .

The video shows how the roof of the house is insulated using this method, that is, according to the truss system:

Advantages and disadvantages of this insulation for roofs

What can be said about the pros and cons of insulation of the roof with polystyrene foam. Let's start with the advantages:

-

low price heat insulation material of this type compared to others;

-

excellent heat insulation qualities ;

-

low specific weight , which allows not to strengthen the truss system;

-

material does not absorb moisture , does not rot;

-

guaranteed service life is 50 years;

-

ease of installation process regardless of the selected technology.

As for the shortcomings, there are not so many of them. The main - Penoplex is a combustible material. And the second minus - if there are mice in the house, then this is the ideal material for their mink. The same goes for ants.

And one more thing. Many people confuse polystyrene with polystyrene foam plates. Both materials are in the same category. But the foam for the roof (its insulation) is not used. This is packing material. Although in everyday life all foam polystyrene materials are called foam plastic.

In the video a specialist talks about the advantages and disadvantages of expanded polystyrene:

This could be interesting! In the article at the following link read about summer house with a terrace .

Conclusion on the topic

So, we have dealt with the thermal insulation of roofing structures with such insulation as Penoplex. Excellent insulation with a large number of positive characteristics. But in any case, the decision on its application must be made depending on the specific situation.