In the arsenal of the construction industry there are various technologies for the use of wood. Having decided to build from wood, the owner of the future house often stops to make a choice - to build a frame house or from a bar. What is better from this try to understand our article.

Houses from a bar began to extend and gained wide popularity before frame. Perhaps this is precisely what explains the prejudice against carcasses, which is found among both amateurs and professionals. Deciding for yourself what is better - a frame house or a house from a bar, it’s not correct to look for advantages (which is categorical enough), but to compare all the advantages and disadvantages of technologies and materials. Evaluating the parameters, you can make a decision.

Selection requires comparative analysis from the point of view of year-round use

Bar and frame: varieties and quality material

To build a practical and modern housing, you should pay close attention to the material.

Bar

Several types of timber are used in construction, the first two are recommended for country houses:

-

Normal (massive). It turns out after the minimum processing of a raw log on a woodworking machine, where it is given a section (square or rectangular). Product humidity may exceed 20-30%.

-

Solid profiled. Wooden blanks are given a more complex profile shape (a thorn-groove system that allows rigidly connecting structural elements).

-

Glued. The moisture content of the blanks (softwood lamella boards) is reduced to 10-12% in the drying chamber. Then the lamellae are selected for quality (external can be from larch, internal - from pine) and glued under pressure.

Frame technology

The basis of the design is the frame, wooden (from lumber chamber drying), metal or sandwich panels. The frame is filled with insulation (ecowool, polystyrene foam, mineral wool) and sewn up with plywood, cement-bonded or oriented-strand boards.

Board in an industrial drying chamber

About wood quality

Quality of sawn timber - quality of construction, so they are chosen carefully. The market presents materials produced from both raw and dried wood.

Natural moisture content (EB) timber is a popular option. It undergoes minimal processing (requires minimal investment) and is therefore cheap. This is its main advantage.

Beam and EB boards are often used in modern construction (respectively, of log and frame houses). Natural processes occurring in raw wood lead to unpleasant consequences:

-

Shrinkage ( shrinkage ) . Once the walls of the massive timber are assembled, they will lose the EB and decrease in size. This feature makes it necessary technological break in construction (at least six months, and often more). Walls of laminated veneer lumber give minimal shrinkage. The use of raw material for the skeleton carcass will result in uneven resizing of the boards (the shrinkage of all the boards is different, it is stronger in thickness and width). At the junction of the boards (and bars) may appear cracks. Such defects become a gap in thermal insulation, break the finish and, alas, require correction by an additional cash infusion.

-

Bio-attack. Mold and fungi feel great in lumber EV. If the wet walls are not left to dry, and immediately begin to warm, moisture will linger and create the ideal environment for the development of microorganisms.

-

Geometry change. Concerns boards. In the process of drying, internal stresses appear in the wood; the board may arch, twist or twist. This happens not only when drying in a stack (in the air); stand in the finished frame can unscrew before the appearance of the gap.

The amount of cracking depends on the quality of drying of the timber

The cost of quality lumber antiseptic treatment is activated; Impregnation often occurs under pressure, which provides deep penetration of the mixture into the wood. This method is not applicable to wet wood; manual treatment of its surface affects only the surface layer and ineffectively protects against rot. An important issue is proper storage; glued laminated timber will be irrevocably damaged if it is left for the winter at the construction site.

Design

No matter what technology is chosen for building a house - timber or frame, construction will begin with the development of a project that depends on the technology:

-

Architectural and constructive diversity. This parameter refers to the possibility of constructing a complex structure with non-standard solutions. Here, as the owner of a more flexible technology, leading frame option. Log buildings are more standardized; the development and creation of unusual elements will take more time and money.

-

Style decision of the project. Trump houses from timber - the natural beauty of the tree - limits the choice of style and the designer's imagination; Diversity can be achieved by combining shades. Due to the quality of finishing materials, the frame house is indistinguishable from brick or wooden.

04

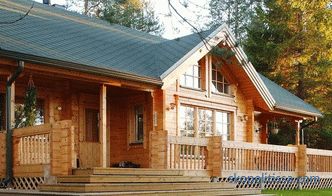

A house from a bar may have an asymmetrical form

On our site you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Construction: Technologies and Structures

Construction companies apply well-honed technologies for the construction of frame and lumber houses. All work is performed by specialized experts under the supervision of a qualified engineer. Asking which house is better - frame or timber, you should start by getting acquainted with the construction technologies.

Features of the construction of the skeleton skeleton

The size and type of construction is limited only by the imagination of the designer and the allocated budget. The frame is mounted on a foundation; after insulation, the structure is sewn up with a finishing or slab material. Next comes the turn of the installation of the floor, ceiling and roof, interior decoration. Communications hiding in the gap inside the walls.

Depending on the complexity of the project, the house is being built in 1-2 months; you can move into it immediately after construction. The house, built with observance of the technological process, will not present in the future unpleasant surprises.

Features of the construction of a log house

Such houses resemble a designer; the elements are laid out in a specific order and fitted into the slots. With detailed instructions and experience from the workers, the work goes smoothly, without delays.

The details of the log house resemble the designer

A roof is erected, the floor and ceiling are mounted; additional wall decoration is not needed. Laying communications is a time consuming and costly process. Channels are drilled in lumber walls, pipes are stacked with regard to future shrinkage.

The wall timber needs a full finish. It is ground (surface and ends), protected with special compounds (only at above zero temperature). Subsequently, the outer walls are polished and painted every 5-7 years, treated with impregnations once a year.

Professional design takes into account the inevitable shrinkage. The final form of the structure will take in 6-12 months (taking into account the training at the place of production and the shrinkage process).

About the thickness of the walls of the log house and the skeleton on the video:

This it may be interesting! In the article on the following link read about the projects of houses with a garage.

Frame and log houses: comparison parameters

After seeing the material and installation features, you can compare glued laminated timber or frame, which better meets the selection criteria. Housing intended for permanent use should be warm, safe and beautiful. Let's compare what the skeleton carcass is different from and the house from the timber: we will consider the pros and cons of each of them in different parameters.

Cost comparison: which is cheaper

Cost is one of the determining factors, since the budget has a limited scope, which is not always possible to move apart. The total amount consists of the cost of materials, transportation costs, salaries to builders, payment for the equipment:

-

Building materials. The initial set for frame housing will cost 20-25% less.

-

Cost of construction. Installation work during the construction of the skeleton carcass requires more highly skilled workers (and higher wages). On the other hand, to raise the beam to the upper levels attract the technique. As a result, a slightly smaller amount (by 10-15%) is spent on the construction of a frame house.

The frame house is the result of a qualified build

In fact, everything turns out not to be so definitely. To frame and log cottages are equal in parameters, you must use quality materials. As a result, a properly constructed skeleton carcass can equal the price or even turn out to be more expensive than an unheated log house.

The construction of a house from a bar is stretched in time, which involves funding in parts. This does not reduce the cost, but reduces the monthly financial burden on the owner and can be a strong argument in favor of this option. Price, by and large, does not help determine the favorite; It is necessary to choose according to other criteria.

Energy efficiency: which house is warmer

In order to understand which house is warmer, frame or timber, we must pay attention to the characteristics of thermal insulation. The energy efficiency index is high both in the frame and in the log house, however, the process of heat conservation passes with the differences:

-

The frame house. If the insulation is chosen correctly (taking into account the climatic region), the walls are a reliable protection against any frost. Housing warms up quickly and maintains comfortable conditions for a long time. Fuel is consumed sparingly.

-

House from a bar. To achieve acceptable energy efficiency, wall thickness is calculated taking into account the climatic zone. The house warms up longer; after the heating is turned off, the heat also retains longer, since the timber is able to accumulate heat. In areas with harsh winter conditions (Far North, Siberia), laminated timber walls need additional insulation.

The technological filling of the walls of the skeleton reliably retains heat

Durability and durability

-

Durability. Here a convincing advantage belongs to houses from a bar - their service life reaches 70-80 years, provided that the external walls are regularly processed. Carcass exploitation lasts 25-30 years, after which the building needs a major overhaul with the replacement of bearing elements.

-

Strength. Both types of buildings work equally well with hurricane winds and tremors. The safety factor of modern materials used in the frame structure is not inferior (and sometimes surpasses) the strength of solid wood.

It might be interesting! In the article on the following link read about the projects of houses for 2 families with different entrances.

Environmental friendliness

Environmental standards are most closely matched to solid-wood timber. All other materials (both glued laminated timber and materials of frame structures) in the production of which glue is used are capable of emitting substances hazardous to health (formaldehyde) into the air.

A mixture to protect lumber walls may contain components that are harmful to health

We compare the advantages and disadvantages of houses

As there is no Ying without Yang, there can be no virtues without flaws; there are both houses built of timber and skeletons. Trying to determine the timber or frame - what is better for building a house, compare the features of the buildings:

Pros and cons of houses from a bar

Using a profiled or glued timber in most cases is more practical than a raw analog, prone to deformations . The advantages of the structure, assembled from a log designer, are:

-

Thermal insulation. The wooden timber produced and laid according to the technology has good thermal insulation properties. It reliably keeps the microclimate of the house, protecting the inner space in the winter from the cold, and in the summer from the heat. If facing and heat-insulating materials are chosen correctly, the walls “breathe” by ventilating the rooms.

-

House Value. Very attractive, given the availability of wood and the ability to refuse to finish.

-

Durability. Built by the rules of a log house for decades does not require repair. To increase the life, it is treated with compounds that protect from moisture, fungus and pests.

A fireplace in a bar-shaped housing does not pose a danger

-

Security. To protect against fire, the bar is impregnated with fire retardant (a substance that slows down the burning). In case of fire, it will help to gain time for the evacuation of people.

-

Aesthetics. Bar-shaped houses are always in trend, polished wooden walls attract with their naturalness.

-

Vapor permeability. It only has a horizontally glued laminated timber, in which the lamella boards and glue layers between them are oriented horizontally. Vertical glued air bar is completely impenetrable.

Disadvantages are:

-

Shrinkage. It should take some time for the wood to dry out and the house to take its final dimensions, decreasing by 3-10 cm. According to the technology, the active process can take 3-6 months if the timber is raw - more than a year. If you finish during shrinkage, it will be damaged.

About the comparison criteria in the video:

-

Raw materials for the home. Not everyone can independently determine the quality of sawn timber. In order not to lose money, you should contact companies with extensive experience and quality certificates for their products.

-

Subtlety of warming. During the construction phase, the walls are carefully smoked; perhaps, after shrinkage, a repeat procedure is required. In order not to get a house-thermos, for insulation do not use foam or polystyrene foam.They trap steam and air, preventing the walls from "breathing." Mineral wool has the best thermal insulation and vapor-permeable properties.

-

Laminated wood. It has high strength, which affects the price and sometimes eliminates the advantage of a lightweight foundation. If the production does not use harmless wood glue, but a toxic (cheaper) option, the walls will emit formaldehyde.

It might be interesting! In the article, read the following link about duplex projects.

Pros and cons of frame buildings

Capital frame houses have undoubted advantages:

-

Construction time. Attractively short - the construction cycle is 1-4 months. All elements are factory quality, assembly takes place without delays and downtime, additional adjustment of the elements is not required.

Frame construction attracts construction speed

-

Reliability. Frame houses are widespread in Europe and America, they are erected everywhere in Canada, characterized by harsh winters.

-

Savings. Wood is used mainly for the frame, which reduces the cost of construction. The wall consists of a frame, insulation and plating; the need for finishing work is eliminated. Also carcasses are characterized by savings during the heating season.

-

Communications. They hide easily in the walls, unlike wooden houses, where gaps have to be left between the wall and the finish, and many people prefer to lay the wiring in an open way.

About how much the carcassis costs on video:

Cons of frame construction:

-

Novelty. Many do not want to risk, noting that modern frame technologies are not time tested.

-

Cheating. Unscrupulous enterprises are deceiving customers, trying to reduce production costs (for example, by reducing the thickness of the profile). The quality of the design falls, as does the credibility of the technology. The manufacture and construction of the skeleton car should be trusted to a reliable developer.

-

Inadequate materials. Chinese-made products can be a source of formaldehyde indoors.

Both the frame and the log house will reliably protect against frost

It may be interesting! In the article on the following link read about the project at home 10 12.

What to choose

After analyzing the data, we can summarize: both technologies have attractive sides; both the frame house and the house from a bar are equally suitable for life. The question "frame or timber - which is better for building a house" should be rephrased to "Which house is better for you", and start from your needs, about what your soul is about.

Provident owners choose construction technology, taking into account future heating costs; The size of the future home and the method of heating (gas) are taken into account. It is also important whether the house will maintain a constant temperature in the winter, or whether it will require a quick warm-up on weekends. In this case, the first place will come not the beauty and durability of a log house, and the performance characteristics of the frame.

Whatever the choice, design and construction it is better to entrust companies with work experience, a solid portfolio and recommendations. The desire to save on materials and work will lead to a violation of technology and ruin any house, frame or lumber.