Today we will understand the topic - clapboard for the facade of the house. We will tell about the varieties of this facing material, about the technology of its installation on the facade, about some of the nuances of the installation process. That is, we will give complete information that will help control the employees of the company that you have chosen as a contractor.

Types of clapboard

Let's start with the fact that the clapboard itself is a material long known They began to use it in America when they were building frame houses and sheathed them with boards that were placed next to each other by adjacent edges. This material received its name because it was already used in Russia for covering cars.

The modern market offers two main options for lining made from wood (the traditional version) and plastic (modern models). We will deal with the wooden, determining its positive and negative sides. But first we will designate that many experts attribute lining to siding category. The reason - the identity of the form and the same technology mounting on the wall. Although it is necessary to indicate that the paneling has been used in construction for a long time, and siding is relatively recent. In addition, the wooden wall paneling has its own separate GOST. So, probably, you should not mix two concepts in one heap.

Wooden variety

Let's start with wooden lining for exterior cladding at home. The term “for cladding” sounds a bit incorrect. That is, there is no material of this type only for exterior decoration. Simply, there are recommendations, for example, that decorative boards made of softwood are more preferable than hardwood ones. Because they contain resin, which is an additional protective substance from natural exposure.

Therefore, manufactured panels are best divided by models in which design and form are distinctive features. Today, manufacturers offer several options:

- Standard form , in which from the side of the spike there is a chamfer, either angular or rounded. It was she who on the wall creates a clear visibility of the junction of the two panels.

- Softline . She has rounded chamfers on both sides.

- Calm . There is no chamfer near the spike. That is the wall trimmed with this model of lining looks, as a plain surface without joints and connections.

- Landhouse . This is a thin plate without chamfers with a well-polished outer surface. The material is expensive, so it is not used on the facades. Although no one forbids. In any case, there are no contraindications.

- Block house . In essence, this is the “Calm” model, only its outer surface is rounded, imitating a log. After such a plating, even a brick house looks like a log house.

- American . To understand what this model is, look at the photo below. Please note that her surface is made under the cone.

For information, we denote that there is double-sided lining. That is, it can be laid by either side, because both are the same. It can not be installed on the facades and in wet rooms, because there are no ventilation ducts in its construction.

Raw material

Now let us tell you what material the wall paneling is made for exterior decoration of the house. Admittedly, the choice is really huge. But since the recommendation of experts - to use products from conifers - we will mostly talk about them.

Let's start with the cheapest options. And this is pine. The low price does not burn about the fact that the quality of this finishing material is worse than the others. This is especially true of the invoice. Figure pine original, inherent only to her. So it will be difficult to confuse.

But it should be noted that pine clapboard has two rather serious drawbacks:

-

very resin is very long standing out, which spoils the appearance;

-

low density of wood , which leads to damage even with minor mechanical loads.

The second most important is lining from spruce. It is stronger than pine, with well-done processing the surface becomes smooth. It is from it that manufacturers often make a block house.

On our site you can familiarize yourself with the most popular designs of houses in which lining and imitation of a bar from a double bar - from the construction companies presented at an exhibition of houses "Low-Rise Country" are used.

And now two expensive options. Larch - solid wood. And the longer it is operated, the stronger it becomes.It never forms colonies of harmful microorganisms; bugs and other insects do not eat it. The only negative - well, very high price.

The next tree is cedar. By the way, he belongs to the group of pine. It has two advantages:

-

high strength ;

-

a peculiar pleasant smell that stands out at the expense of tar, it is he who scares mosquitoes away from home.

And just a few words about lining of hardwood. There is practically non-excised assortment: beech, oak, alder, linden, a large number of exotic species. It should be noted that hardwood lining has a shorter service life and high thermal conductivity.

Selection Criteria

Denote some purely technical points to consider when choosing a wall panel:

-

Wood Grade . The best option - 1 grade.

-

Drying technology . Better chamber than conveyor.

Mounting technology for wall clapboard on the facade

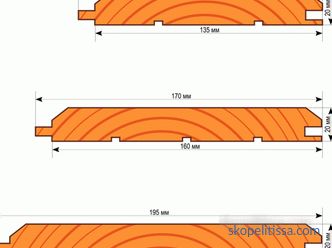

There are two ways of covering the house with clapboard: vertical and horizontal. Consider both. But first you need to talk about how to calculate the amount of material for the facade. The calculation itself is simple, because the standard mathematical relationship is valid: the facade area should be divided by the area of one skin element.

The first indicator is the length of the house multiplied by the height of the wall. In some cases, if there are many windows and doors on the facade, their areas are deducted from this value. But more often they do not. The second is the length of the wall panel multiplied by its width. And since the model range of the material is large enough, you will have to measure the dimensions of the selected panels.

On our website you can find contacts of construction companies that offer the service of finishing and warming houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Horizontal installation of wall paneling

Regardless of which house is sheathed by clapboard, it is necessary to build a crate of wooden slats or galvanized steel profiles used for the installation of drywall under the cladding. The second option is preferable, because the metal does not change its dimensional parameters under the influence of varying humidity and temperature, it will not lead or warp it.

It is necessary to make a reservation at once that a vertical frame is installed under the horizontal wall paneling. The mounting step of its elements depends on the length of the finishing panel. This is usually 2.6; 2.7 or 3 m. That is, two joined panels should be connected on the same profile. Therefore, first on the wall from any corner of the building lay the length of the lining. It is clear that not always the last element of the skin will fit completely. Therefore, it will be cut.

And then vertical lines of intermediate lines are drawn between them with a pitch of 50-60 cm profiles. There are no strict standards here, so an error of 5 cm is not a problem. Vertical lines provide a plumb bob.

Next, on the marked marks with a step of 50-60 cm, direct suspensions are installed. They are attached to the wall with screws. If the house is brick or concrete, then at first they drill holes under the dowels, where the latter are driven with a hammer.

It is necessary to immediately indicate that the lathing should form a vertical plane, therefore it is necessary to set the profiles to be set strictly not only vertically, but also in the same plane. They do it this way:

-

Set one profile at the edge of the facade, that is, in the corner of the house. He is strictly exhibited vertically by the level and immediately attached to the suspensions with self-tapping screws.

-

Then strong threads are tied to the lower and upper end of this profile.

-

Their free end pulls into the opposite corner of the house (front).

-

First tension the upper thread. Expose it horizontally, and then check and vertically. It is under this level that the profile is set, which is attached to the hanger by the upper end.

-

Then the profile is set vertically, and the lower end is fixed to the lower direct suspension. It turns out that two profiles located at different edges of the facade form one plane.

-

Between them they stretch two or three more threads, which, again, purely visually form the vertical plane of the skin.

-

According to them they expose intermediate elements of the batten.

Watch a video that shows how to assemble the crate on the facade of the house:

It can be interesting! In the article on the following link read about wall cladding in a wooden house.

If it is decided to warm the house outside, then before the installation of the frame it is necessary to lay the insulating material. These are usually foam polystyrene plates or mineral wool mats. Insulation just fit on direct suspensions, tightly pressing it to the surface of the wall. Please note that the mineral wool will have to close the vapor barrier membrane from the outside.

So, everything is ready for the immediate lining of the house with clapboard outside. You can start the process from the bottom or top from any angle of the structure. The main requirement - the groove of the panel should look down and the spike up. The panel is simply applied to the crate, leveled horizontally and fastened to it with screws, studs. Mounting slot. As for such an attachment, after installing the top row, the elements of which will be inserted with a spike, the fastener heads will be closed with a spike. So nothing will be seen.

Today, manufacturers offer a special type of fastener - kleimmer. Convenient and reliable fastener with which assembly speed is increased. It is recommended to use it if it is necessary to dismantle the clapboard after some time without breaking the panels.

The assembly scheme is different. For example, collect one row completely, then move to the top or bottom. Or they assemble two or three panels, for example, of the lower row, then install 2-3 lining boards in the second, then the third row, then return to the first one, continuing to fill it. That is, the masters use the option that is convenient for them.

And the final touches:

-

installation of the plinth skirt , which will close the bottom edge of the bottom row.

-

mounting of the corner elements .

How to fix the wall paneling in the video:

It might be interesting! In the article the following link read about painting the wall paneling inside the house.

Vertical lining

The cladding of the facade of the house with vertical clapboard is almost the same as the previous technology. Different layout of the elements of the batten and the panels themselves. The first set horizontally, the second vertically.

But there is one very important nuance in this technology. It is not necessary to assemble panels so that several long horizontal seams form on the facade of the house. Therefore, the finishing elements are assembled in a staggered manner, that is, with a shift in length by half of the panel. For example, the first panel is installed solid, the second one is cut in half and one part is mounted near the first one. The next one is complete, then half and so on to the opposite corner of the house. The rest on top of the laid set in one piece. Of course, under the roof will have to adjust all the panels in length.

Price component

So, the installation process was sorted out. I would like to give a little space on information on the price of lining for exterior cladding at home. This facing material is sold by the piece, taking into account the area of plating, and cubic meters. Therefore, consumers often face the challenge of converting from one unit to another.

Pricing is based on the type of wood used, so prices are on average in Russia:

-

variety " Extra " - 33000-35000 rub. / m³;

-

1-2 grade - 13000-15000 rub. / m³;

-

grade 3 - 8000 rub. / m³

Of course, the cost of production will also depend on the size parameters of the panel. The more they are, the higher the price. For example, lining 1-2 varieties of pine sizes:

-

12.5х90х1500 mm costs 13,000 rubles. / m³;

-

18x95x1500 mm - 25,000 rubles. / m³

The specialist's reasoning on how much lining costs, in the video:

It can be interesting! In the article on the following link, read about how to choose lining for interior decoration of the house.

Conclusion on the topic

Among consumers and specialists there are fans of lining, there are also those who are cool about this finishing material. But in any case, it is still popular, especially among those who are building frame-type houses, or trying to modify the facade of an old house. Finishing of this type is inexpensive, installation is simple. It is possible to conduct insulation processes. The material itself can be painted, giving the house an original look, or covered with a colorless varnish, leaving the wood pattern unchanged.