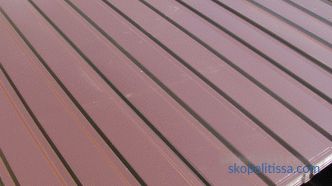

Profiled - material that has been used in construction for a long time. But its popularity grew dramatically when manufacturers began to offer panels of different colors instead of a non-dull gray sheet. The demand for profiled sheets only grows from year to year, the reason is the low price with high technical and operational characteristics. In this article we will talk only about one type of this material - professional flooring C8. Let us designate why this view received such marking, what are the dimensional parameters of the sheet, where it can be used and how to mount it.

What is profiled

Profiled sheets are made of galvanized steel sheet, which The shop comes in the form of a roll. As mentioned above, manufacturers offer three varieties of this building material:

-

galvanized ;

-

galvanized painted ;

-

galvanized with polymer coating on the front side.

So this sheet is unrolled and rolled through a rolling mill, in the construction of which rolls are installed, forming a wave of profiled sheets. That is, the process of creating a form is cold rolling. No heat engineering processes. The dimensions of the rolls determine the size of the waves of the material. If necessary, increase or decrease this parameter, change the rolls.

Now, as for the varieties of corrugated flooring in terms of protective layers. By itself, the galvanized layer is an excellent protection of steel against metal corrosion. In this condition, the decking last up to 10 years. If its front side is painted with protective paints, then the service life increases to 15, and in some climatic conditions up to 25 years. And the profile covered with polymer can be operated for up to 50 years. But there is one condition - you can not damage the protective layers. If this happens, the lifetime is immediately reduced to 5 years.

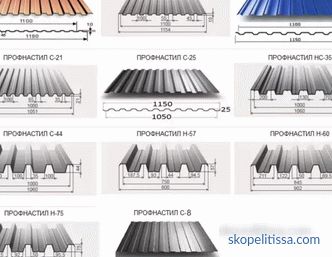

Now we turn to the classification of profiled sheets. Here are three main positions:

-

"H" is a bearing profiling, which is used as a roofing material to create non-removable formwork for floors, to build protective structures, hangars, garages and other small building sites.

-

"C" is a wall variety. From the very name it becomes clear that more often this type of profiled sheets is used for wall cladding and ceilings. Rarely they are used as roofing and erection of fences. As for the roofing, it can be small awnings, canopies. The main requirement for the wall version used on the roofs is mounting under it or a solid crate, or discharged with the installation step of elements in the range of 30-40 cm.

-

HC 18> is the so-called base-wall material. This is a kind of intermediate stage between the first two. That is, the sheets have sufficient rigidity, but at a price cheaper than the carrier variety. In fact, it is a universal brand that builders today use everywhere.

On our site you can find contacts of construction companies that offer the service on finishing and warming houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Technical characteristics of the professional sheet C8

So, having understood what the profiled sheets are, we proceed directly to the topic of the article. And we will first deal with the technical characteristics and dimensional parameters of wall sheeting 8.

Let's start with the raw material. To do this, use cold-rolled steel grade or 01, or 220-350. Sheet thickness - 0.4-0.7 mm. The thicker the sheet, the higher the strength characteristics of the material, the higher its price.

But pricing is influenced by another parameter - a layer of applied zinc. According to guests, this size varies in the range from 140 to 275 g / m². Today on the market there are profiled panels made of galvanized sheet, the thickness of the protective layer which is within 100 g / m². This profiled material is much cheaper. Although selling it as a standard option. This is a hoax, be careful, ask for a certificate of quality.

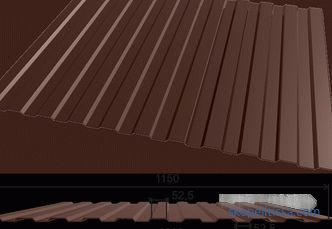

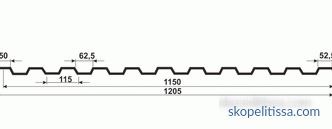

Now for the parameters. The designation of the brand is - C8-1150-0,5. That is, the profile height is 8 mm, the useful width is 1150 mm, the metal thickness is 0.5 mm. It should be noted that the total width of the panel - 1200 mm.

As for the length of the profiled sheet of the C8 brand, then, like all modifications of the professional flooring, this parameter varies in a rather large range: from 0.5 to 13 m. And this is a big plus, because it is possible to carry out trimming directly in the shop under the required dimensional parameters of the framed plane. That is, for example, on the wall in the process of its lining will not form joints and seams, which spoil the appearance.

And the last - profile type. At the wall profiled sheet 8, the wave view is only trapezoidal.

The requirements for professional flooring of grade C8 by the standards

GOST regulate the following requirements :

-

On the front surface of the profiled sheet there may be slight damage and wear, if they do not reduce the protective properties of the material.

-

The following deviations from dimensional parameters are possible: length - plus or minus 10 mm, width 8 mm, height of the corrugations - 1 mm.

-

sheet waviness is allowed, but not more than 1.5 mm.

-

Allowed sickle in limits of 1-1.5 mm per 1 m length.

It can be interesting! In the article on the following link read about decking for the fence.

Polymer coatings

I would like to say a few words about the polymer coatings that manufacturers use today to increase the life of the C8 professional sheet.

-

Polyester . This is the cheapest version of the protective coating. It covers the panel with glossy film. The thickness of the applied layer is 25 microns. This is a very thin layer that does not withstand mechanical loads. But among private developers these particular sheets have received great popularity. And if you competently carry out their installation, then even under harsh operating conditions, they will last about 25 years.

-

Matte polyester . In composition, it is one to one, which is glossy. But the rough structure does not allow to put it with a thin layer. Therefore, the approximate thickness - within 50 microns. Hence, higher strength and wear-resistant characteristics. And the service life grows to 40 years.

-

Pural . This polymer is applied on a galvanized surface in the same layer - 50 microns. This is a completely different polymeric material, but rather a mixture, which includes polyurethane, acrylic and polyamide. Very durable coating that will last at least 50 years.

-

Plastizol . In fact, it is polyvinyl chloride (PVC) and plasticizers. Apply it with the thickest layer - 200 microns. Hence the high strength characteristics. But with a high temperature, this polymer is not friendly. And it must be taken into account when choosing it. It is possible to add to pluses of polymer that today producers make it with a stamping. That is, with imitation for different building materials: wood, stone, leather, sand, and more.

-

PVDF . This is a mixture of acrylic (20%) and polyvinyl fluoride. This is the most modern type of coating, the most durable and most expensive. The service life is 50 years, with a thickness of the applied layer of only 20 microns.

So, the price of C8 corrugated sheet depends on the polymer with which the material was processed . Therefore, immediately we denote the price component of the profiled sheet of the brand C8-1150-0.5. That is, we will not affect the cost depending on the thickness of the sheet.

-

Decking, coated with glossy polyester , costs 215 rubles per 1 m² of coating.

-

Coated matte polyester - 250 rub. / m²

-

If Pural was used, then the price is 430 rubles.

-

If polymer coating - it is plastisol, then such a professional flooring is worth 380 rubles. per square meter.

-

And the last one is PVDF . The price of such a professional sheet is 360 rubles. / m²

The video tells about the dimensions of the professional flooring grade C8:

It can be interesting! In the article on the following link read about the barn from the professional sheet: the features of the material and the stages of construction + photos and videos.

Technology of installation of professional flooring of brand C8

In principle, all profiled sheets are mounted in the same way. That is, there are certain rules that can not be neglected. We missed one thing, got a poor quality of the final result. Let's denote these rules:

-

As mentioned above, the adjacent sheets, regardless of whether they are placed in a vertical, horizontal or inclined plane, are overlapped in one or two waves.

-

If two adjacent sheets are joined in the longitudinal direction, then the displacement of one relative to the other should not be less than 10 cm. should be more.

-

The profiled is attached to the sheathing or frame with roofing screws with a hexagonal head. In this case, the fastener must be supplied with a gasket made of neoprene rubber, which, under the influence of different temperatures and sunlight, does not change its size and operational characteristics.

-

Mounting is carried out only to the lower wave . If there is a need to bond together two adjacent sheets, then use short screws, which are screwed into the upper profile of the place of overlap of two waves.

-

Self-tapping screws must be twisted strictly perpendicularly to the laid sheet. It is not allowed to mount with a skew, because in this way a leak-tight fit of the neoprene gasket to the plane of the profiled panel is obtained. That is, a gap is formed. This is especially important in the process of laying a professional sheet on roofing structures.

-

Strongly tightening fasteners cannot be . Also it is impossible not to twist their . In both cases, a leaking compound will occur. That is, the roofing screw should press the decking to the crate, and not press it with force.

The video shows the rules for attaching profiled sheets to a crate or frame:

This can be interesting! In the article on the following link read about 3 main sizes of corrugated sheet for the roof: marking and form.

Conclusion on the topic

C8 grade professional flooring with its not very high strength characteristics is quite popular among suburban developers. The low price, plus the fairly good stiffness of the panels makes it possible to use them in a wide list of construction operations. In addition, in recent times, the finishing of houses and economic blocks with a professional flooring has become popular, where again the C8 brand is used.

Rate this article, we tried for you