The enclosure protection of the plot performs several functions: demarcation, protection of the area from outsiders and creation of a single picture with the house. Therefore, the fence should be not only durable, but also aesthetically attractive. The optimal and relatively low-cost construction will be a foundation for a fence with brick pillars, laying directly the pillars themselves and filling the spans with a choice of materials — a board, corrugated flooring, a working net, or forged decorative elements. The combination of the two materials will give the fence attractiveness and will allow the host to choose how to fill the spans at his discretion, based on the overall design and the estimated budget.

Calculations and preparation for work

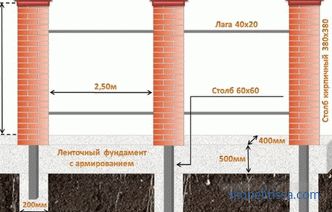

The first stage of the preparatory work - calculation of the number of pillars for the future fence. Usually they are installed with a distance of 3 meters from each other. But, if the length of the site exceeds 150-200 meters increase to 4. This is due to the high cost of installing brick pillars at such a distance.

For accurate calculation, first locate the corner posts, the entrance gate and the gate. After that, the distance between them is divided into spans of an accepted size.

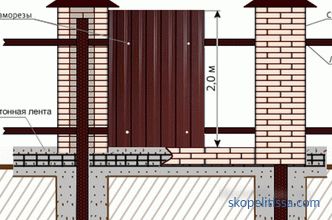

The height of the pillars usually varies from 2 to 2.5 meters. These are the optimum sizes suitable when filling spans with a grid or a professional flooring. Above the fence is not recommended to do - for this you need to deepen and strengthen the foundation so that it can withstand the effects of the wind. This is especially true if the spans are made of corrugated board, which has a large sail.

After a preliminary calculation of the supports along the perimeter, the rope is pulled and stakes are driven in at the places of future pillars . The calculation of the number of materials for the pillars and the preparation of the foundation will depend on the choice of the type of foundation and the method of laying bricks.

Filling the foundation

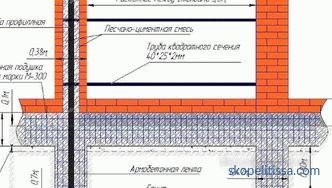

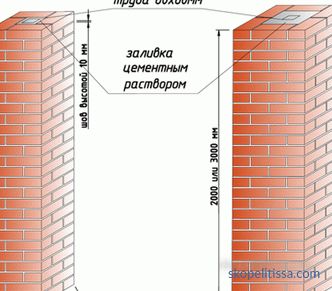

The simplest type of foundation is tape-column. For its construction, after marking the area around its perimeter, a trench 30 cm deep and about 40 cm wide is torn off. At the places of the brick columns, 90 cm hollows are made. The total depth of the pit for the support will be 120 cm. For the temperate zone, this depth will protect the foundation from freezing the soil. This will eliminate its displacement and destruction.

The trenching can be done manually or using equipment. Skilled craftsmen recommend the first option - the work will be much more accurate, but the time costs will increase about 2 times.

The trench is reinforced with metal rods with a diameter of 14-18 mm. This will further increase the strength of the foundation and compensate for the load when the soil subsides. Metal profiles or pipes are installed in places of brick pillars. Filling of the base begins with deepenings under columns. With the help of the construction level, the vertical position of the pipe or profile is controlled, and the rest of the tape is then poured.

A fence with brick pillars on a strip foundation is considered the best option - it combines reliability and relatively small time and financial costs.

More robust, but costly in terms of materials, will be the construction of a roaster foundation. Rostverk - is the upper part of the foundation, which consistently fastens the pillars or piles. The rostver is also present in the ribbon-column foundation, but it is at ground level.

For his device, formwork is mounted - 30 cm from the ground around the perimeter of the excavated trench. Reinforcement is made as in the case of a tape foundation, after it the concrete form is poured.

After the foundation has been poured, 2 or 3 weeks should pass before it is completely dry. Then you can build brick pillars for the fence.

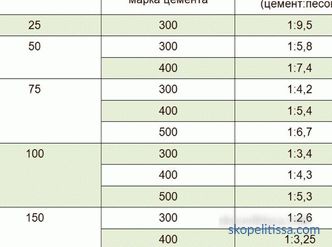

Mortar preparation - proportions and rules

Sand and cement - the main components of the solution. The mixing ratio is standard: 1 part cement, 5 or 6 parts sand. The latter is better to choose the small fraction. The higher the cement grade, the better the solution will be. It is advisable to choose no lower than M400. Some masters add detergent or liquid hand soap - this provides the best plasticity of the solution.

To facilitate mixing, sand and cement are first mixed in a dry state and then water is added. The main thing is to choose the optimal ratio - the solution should not spread, but also not be dry.

For decoration, special additives are added to the solution, which are sold in hardware stores. For example, it may be simple soot. A small amount will give the solution an almost black color, which will favorably emphasize light brick.

Which brick to choose

On our site you can find contacts of construction companies, who offer the service of building and designing fences. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

One of the main tasks in the construction of the fence will be the choice of the base material - bricks. It should not only ensure the reliability and durability of the building, but also have an attractive appearance. The modern market offers the following types of bricks:

-

silicate;

-

ceramic;

-

clinker;

-

hyperpressed.

The classic versions are silicate and ceramic. The first one is made of quartz sand; the second is made of clay. These are universal options, possess the good durability and moisture resistance. One of the main characteristics of a brick is the number of freeze / defrost cycles. According to this indicator, clay brick is inferior to silicate brick, which can withstand up to 60 cycles without loss of performance.

The clinker brick is the most durable of the types presented. It is made from refractory clay at high temperature. Maintains up to 150 cycles of freezing and thawing. Excellent technical characteristics are combined with a variety of colors and shades. Buildings of this material, while respecting all technologies, retain their strength and aesthetic characteristics for over 100 years. The only negative is the price is higher than on silicate and ceramic.

Hyper pressed or Lego brick. Due to the high pressure treatment, the particles of the material are bound at the molecular level, which provides it with strength along with the clinker level.

Any of these types can be used to build brick pillars for the fence. The main selection criterion will be a financial issue.

How to choose a quality brick for masonry pillars, look at the video:

Brick masonry technology

Before you start laying bricks are laid with ruberoid or special waterproofing. It will not allow direct contact with water.

Depending on the width of the brick pillar for the fence, there are two most popular ways of laying:

-

and a half bricks;

-

laying in two bricks.

In the first case, a pole of 380x380 mm is obtained, in the second case, 510x510 mm. The first option is more advantageous in terms of solution consumption. The support profile for the post is usually taken 80x80 mm. This will greatly reduce the gaps between it and the laying and will require less mortar to fill them. In the second case, the support will be more solid and massive, but will require filling the gaps with a large amount of solution.

The bricks are laid according to the scheme. The horizontal and vertical plane is controlled by the construction level. The next layer of brick overlaps the seams of the previous one. Gaps between the iron support and the masonry are filled with mortar and compacted.

To obtain ideally smooth seams, metal rods of round or square section with a diameter of up to 10 mm are used. These rods are laid around the perimeter of the first row of bricks from the outer edge. The site is filled with a solution with a certain margin to the center. The brick is laid on the bar with one side, and the second is aligned to the construction level. After filling the vertical seams, the procedure is repeated with the next row. The rods are removed from the previous row. This technology allows you to control laying and make the seams neat and smooth.

After the brick pillars were erected to a predetermined height, a decorative cap is installed on the end face. Various options can be found at building materials stores. The cap can be metal, ceramic or concrete. It is installed on masonry mortar. The cap protects the pillars from moisture and rain.

For brick masonry technology, look at the video:

It might be interesting! In the article the following link read about the fence of the metal profile.

Installation of the fence and the gate

At the stage of laying the pillars, it is necessary to decide on the material for the spans. If metal materials (decking, forged grilles) are chosen as materials, and also, if the choice was a wooden fence with brick pillars, then metal elements are welded to the supporting posts of the posts at the same height for arranging horizontal lintels. For reliable fastening two jumpers are constructed.

In those places where gates and gates are located, it is recommended to install three jumpers for reliable fastening of the valves, since these elements are constantly under load and are used.

An alternative to the listed materials would be laying a brick fence between the pillars. This is a more time consuming process. Each subsequent row must be aligned in a horizontal and vertical plane. The foundation for such a fence must be strong to keep a lot of bricks.

The advantages of this type of fence are the possibility of using various bricks in color and texture, which will give the fence an attractive look and personality.

Photo-examples of fences with brick pillars

This can be interesting! In the article on the following link read about the plastic fence.

Conclusion

Brick fence posts are the most common and affordable option. The variety of types and various possibilities of filling the spans will help to choose the most suitable for a particular plot and house design. Properly arranged foundation and quality masonry work will make the fence a reliable fence that will last for decades.