In those cases where, for whatever reason, it is not possible to fill in a monolithic foundation, we can consider the possibility of mounting the foundation of a building from concrete foundation blocks. In general, these are seemingly ordinary standard blocks, but with much greater moisture resistance and frost resistance.

Block foundation 200x200x400

The foundation block is a concrete product that has reached the maximum level of strength in a special form. Foundation blocks are produced serially, in accordance with GOST 13579-78. Such foundation blocks are used for the construction of various types of foundations, for example, foundation tape or piles (pillars).

The blocks for the foundation during manufacture have standard dimensions:

-

Width 200 mm

-

Height 200 mm

-

Length 400 mm

At the same time, the weight of one block is only 32 kg. Thus, the foundation block 200x200x400 is the optimal material in the case when for certain reasons it is impossible to use heavy construction equipment on the site.

Production of concrete blocks

The basis of the production of fundamental concrete blocks - mortar based on concrete. Into its structure enter additional components that give to ready blocks various functional characteristics. The following can be used as fillers:

-

Expanded clay

-

Gravel

-

Crushed stone (hard rocks)

-

Slag waste of metallurgy

For fundamental concrete blocks, the sizes of the fractions of additional materials are very important. They must not exceed 20 mm.

As for concrete, in the production of standard fundamental blocks are used:

-

Autoclaved concrete

-

Heavy concrete

The group of autoclaved concrete includes solutions based on gas silicates and aerated concrete . The main binding components in them are cement and lime. Heavy concretes are distinguished by increased density.

If it is necessary to provide products with additional clear geometric forms and to increase the strength of finished blocks, the addition of reinforcement elements is used.

On our website you can find contacts of construction companies that offer the service of an audit of construction work. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Arrangement of strip foundations

Given the above, it is clear that the use of fundamental blocks is advantageous primarily in the construction of private buildings of small size. This technique significantly reduces material costs and time resources spent on construction. Work takes much less time, given the use of high-quality pre-finished materials.

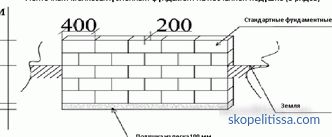

This is the approximate diagram of a shallow-foot strip foundation

-

First you need to dig a trench. Its level should be 20 cm below the level of soil freezing.

-

A mixture of gravel and sand for the foundation is poured (layer of 20/30 cm pad)

-

Rows of fundamental blocks are placed on the pillow.

-

When making masonry, the seams are tied up using steel reinforced rods, if necessary.

-

Rows are mounted until reaching the height of the basement (in accordance with the project).

-

Construct a moisture barrier overlay of 2 layers of waterproofing material

-

Equip the blind area of the foundation along the perimeter of the base.

Applications

For the use of small-sized fundamental blocks there is only one limitation - the composition of the soil. The soil must be poorly lousy. The rest of the product can be used on any other soils and in any climatic zones.

Concrete blocks 20x20x40 are most commonly used for the foundation of wooden houses, foam blocks, low-rise cottages. Of them perform:

-

Tape and column foundations

-

Underground garages;

-

Underground spaces and basement walls

-

Ground floors

In addition, this material is excellent for the construction of walls and between wall partitions of technical buildings, fences and road restrictions.

Classification

In order for buyers to immediately understand the quality characteristics of concrete blocks for the foundation and their purpose, manufacturers use a special classification that determines the mass and dimensions of the product, the place where it is used. The following types of blocks are distinguished:

-

Ф - blocks for the stacked type of foundation, used for the construction of columns.

-

FL - blocks that are used as a cushion for arranging strip foundations.

-

FBS - used in the construction of zero cycles, basements and subfloors.

-

BF - tape type products.

-

FR - heavy concrete blocks used for three-hinge frames are used in the construction of external and internal walls.

-

FBP - hollow concrete blocks

It can be interesting! In the article on the following link read about the wooden foundation house.

Advantages of standard fundamental blocks

Concrete block 200x200x400 is produced in the shape of a rectangle. In its production uses a heavy concrete mortar (mainly class B7. 5).

Modern technologies guarantee the quality of basic concrete blocks produced by the industrial method. Technological processes and geometry of products comply with GOST No. 6133-84 (Technical conditions).

The main parameters of the products are indicated in GOST № 13579-78:

-

Material strength -150 kg / cm²

-

Frost resistance index - 15 cycles

-

Thermal conductivity index - 1. 15 W / m ∙ K

-

Mass - 31. 2/31. 7 kg.

The advantages of concrete foundation blocks

The quality characteristics of the concrete block 200x200x400 provide a number of positive aspects when using the material in construction.

-

There is no need to hire additional labor and rent special equipment, which, respectively, reduces the cost of construction.

-

In contrast to the arrangement of monolithic bases, there is no need to first assemble and then dismantle the formwork for the foundation.

-

The speed of the foundation is several times higher than when pouring the usual one.

-

Foundations of concrete blocks can be erected at any time of the year.

-

Immediately after laying the foundation blocks, you can begin to erect the walls of the building.

Thus, the production by the method of vibropressing provides products with a decent level of durability, permeability and stability to the effects of temperature differences and precipitation.

Use on unstable soils

Using fundamental concrete blocks is possible on ground of any type. However, if we are talking about unstable soil, such as heaving, marshy, man-made, peaty, then when building the foundation of concrete blocks, you should follow some recommendations. So, the blocks are immersed in the ground below the point of freezing. They are equipped with a suspended grillage. At the request of the developer, it can be made of wood, metal or reinforced concrete.

Often this construction technique is used in the construction of frame and wooden structures.

The process of laying the foundation of blocks on the video:

It might be interesting! In the article on the following link read about waterproofing base plate.

Summing up

Taking into account all the above, it becomes clear that if the ground allows, the foundation blocks are almost ideal for the production of the foundations of small country houses and technical structures such as baths, summer kitchen, garage or greenhouses. The main thing is the exact calculation and the correct installation.

Rate this article, we tried for you