Finishing roofing is one of the most important elements of a building, which takes the “blow” of all atmospheric phenomena - wind, rain or snow. Since the cards of the roofing profiled sheet of a complex wave-like shape, there are certain rules for fixing corrugated roofing, which are discussed in this article. You will learn what screws for the roof of corrugated board are needed, their mounting schemes and consumption per 1 m².

Correct mounting of the roofing sheet with self-cutting screws

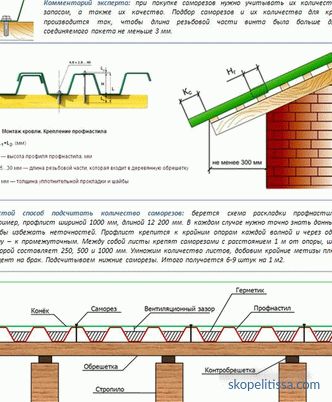

When installing the outer surface The roof is very important point is the correct use of fasteners. With a strong wind, tearing the load on the topcoat can be up to 600 kilograms per square meter. In addition, excessive deformation of the sheet when tightening the screw, can lead to a violation of the tightness of the roof at the place of its installation. This often leads to the need for a complete reassembly of the roofing pie in order to locate the leak and eliminate it. The first thing you need to understand - what screws are needed for corrugated roofing. For this, not every screw is suitable, so you need to select a special fastener that provides for pressing the sheet against the sheathing and tightness of the fastening.

When screwing in the screw, a screwdriver is used with control of the tightening force. The screw is installed in the cavity strictly perpendicular to the surface of the profiled sheeting; during installation, the surface is not allowed to bend inwards. If the screwing turns out to be skewed, the screw must be turned out, to drive a wooden plug into the hole with the use of PVA-M glue and install the screw correctly.

A profiled sheet, CH35 or CH45, is used to make the roof finish. Accordingly, fasteners are used in the form of self-tapping screws with a length of 20 to 50 millimeters:

-

when installing in the hollow of sheet - 20 mm long; >

when installing in the place of overlap of adjacent sheets - 50 mm;

-

for fastening ridge strip through profiling - 50 or more millimeters depending on the roof construction. In some cases, you can use longer fasteners.

When you buy screws, you need to take into account a large percentage of their quality rejection. The main drawback of the screws is the insufficiently sharp part of the drill end, which can lead to rolling of the edges of the holes and deformation of the sheet. The diameter of the screw is selected within 4.8-6.3 millimeters.

How to install roofing sheets on the roof

order, ensuring its strength and tightness.

The installation of individual sheets starts from the bottom left. On the first vertical row there is a pediment overhang no more than 40 centimeters wide. But the sheets do not fit in orderly, but in a staggered manner, that is, the second will be the first sheet of the second vertical row, then the second second vertical row, then the second first. Thus, the slope of one side of the roof is formed, after which installation of the second one begins in the same manner. Vertical rows need to be monitored with a mounting cord.

Vertical overlap of sheets should be at least 20 centimeters, this indicator horizontally depends on the construction of a professional flooring. Under normal conditions, such an overlap is performed in a single wave, in more severe climatic circumstances - in two. The decision is made at the design stage depending on the climatic conditions in the construction region.

For a standard sheet of 0.8x1.1, the distance between the screws is 0.5 meter, that is, there are 4 pieces per 1 m 2 . But it is necessary to take into account that along the lower edge of the sheet of the first row of the roofing pie, the fastener is installed in each lower shelf.

The gable edges of the finishing cover are fixed at intervals of about 250-300 millimeters. In addition, the overlap side, ridge and wind straps are attached with the same parts, increasing their specific consumption.

The average consumption of fasteners is assumed to be 8 pieces per square meter, with 4 pieces 35 mm long, 2 pieces - 20 mm and the same length, from 50 mm. But it must be kept in mind that this indicator directly depends on many factors:

-

roof construction ;

-

sheet thickness finish coating;

-

applied profile .

How not to fix the roofing on the roof is shown in the video:

The fastening of the professional sheet with self-tapping screws on the roof is one of the most important moments for the device of the roof and it must be considered when installing it.

On our site you can familiarize yourself with the most popular in Moscow suburbs for the construction of a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Determining the number of fasteners for one sheet of corrugated

It would be easiest to answer this question with a simple recount. If there are 8 self-tapping screws per 1 square meter of the roof, and its area is: 0.8 x 1.1 = 0.88, it is logical to make a recalculation as follows: 8 x 0.88 = 7 pieces with rounding. But to consider the specific consumption of fasteners in this case simply does not make sense, it is much easier to count the total area of the roof and use the generally accepted consumption rate per square meter. This value is always calculated when designing the structure. In addition, such a calculation is made taking into account the characteristics and dimensions of the profile.

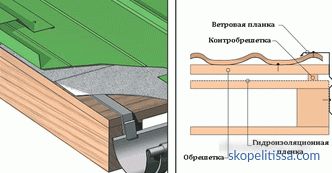

Installation of waterproofing and battens for professional flooring

Support surface for finishing coating - crate - made from a board with a thickness of 25 millimeters or sheet materials like plywood, chipboard, OSB or other similar ones. The material is attached to the rafters with nails or screws. Waterproofing is installed on top of the crate, most often roofing material is used for this, but it is possible that thick plastic film is used.

Clearly about the installation of a profile made of corrugated flooring - in the following video:

Installation is done in the following order:

-

Crate from the board is of two types - sparse or solid. The latter is performed with the distance between the boards up to 5 centimeters, the step of packing rarefied provides for the distance between the boards up to a meter depending on the format of the sheets of the finishing coating.

-

Boards are packed , starting from the bottom edge of the truss system horizontally.

-

Two or three boards in the under-pawn space are installed close to without gaps .

-

Over waterproofing waterproofing of roofing material is installed. Laying starts from the bottom edge of the roof. Sheets are laid with an overlap of up to 15 centimeters, the joint is glued with construction tape or connected with the use of bitumen mastic.

The main task of waterproofing is to seal the support base for the final coating and to drain the condensate from the roofing space.

This coating structure is used when installing a "cold" roof. For warm, you need to form a roofing pie using insulation and vapor barrier films. The use of roof insulation reduces heating costs by up to 20-30%.

On our website you can find contacts of construction companies that offer services design and repair of the roof . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Causes of roof leaks

This phenomenon can be only as a result of installation errors or breakthroughs in the insulating material. Equal installation of waterproofing on the batten is also important. If there is swelling of the material in certain places - leaks are inevitable, and above all - from condensate, even if the flooring is perfect.

The second reason for leakage may be poor-quality trimming of sheets, leading to deformation and loss of flatness of the roofing material.

Installation of roofing

Fastening of corrugated roofing with screws on the roof, as already mentioned above, is made from the lower left corner of the ramp. The works are carried out in the following order:

-

First of all, a drip is installed along the bottom edge of the sheathing - a special bar for draining condensate from the under-roof space to the storm water inlets.

-

The first sheet is placed on the sheathing parallel to the rafters, and the size of the overhang is formed. For a standard sheet, it should be no more than 40 centimeters.

-

Proper installation of corrugated roofing with self-tapping screws on the roof is carried out taking into account the above requirements - installation in a stream at a right angle.

It can be interesting! In article on the following link, read about how the roof is made of corrugated .

-

The second sheet is set with side overlap in one or two waves, which depends on both the coating properties (thickness) and the roof operating conditions characteristic of the construction region .

-

Further assembly is carried out in a staggered order to complete covering of the ramp.

-

In the same way the second ramp is covered, after which wind slats are installed.

-

The last is the operation to mount the ridge bar , which finally forms the roof covering.

Cutting professional sheet

If it is necessary to fit individual cards at the place of installation, different methods are used. It should immediately be said that cutting methods can be different, but you should immediately caution against the use of technologies that lead to the heating of the sheet, for example - cutting with a grinder. When this occurs, the detachment of the paintwork, leading to its further destruction in an accelerated mode.

Other available methods should be used: metal or manual scissors for metal shears.

Which self-tapping screws are suitable for installing professional flooring

Special coating is used for such a coating fasteners. In Russia, screws for the roof of corrugated are made with the requirements of GOST 17917-86. A distinctive feature of such screws is the presence of the drilling part at the front end, which allows drilling material in the process of screwdriving. The second feature is that the head is made in a hexagon shape, and the hot stamp of the manufacturer is applied on the end face. There is also a bearing washer with a plastic gasket under it. (See Fig. 2.)

The use of other fasteners, as a rule, leads to numerous leaks in the roofing.

It might be interesting! In the article on the following link read about the project of a house with a wavy roof .

Conclusion

Despite its apparent simplicity, installing a professional sheet requires certain skills and experience - starting with knowing how to “tie up” the cards between each other and ending with the skill of properly screwing in the self-tapping screws - so that they go to the desired distance. Therefore, the installation work must be trusted professionals who perform them quickly, efficiently and with a guarantee.