A wooden house is a separate category of construction. Its smell carries us to childhood, and the atmosphere that is created inside fills us with comfort and gives a feeling of calm and tranquility. It is easy to live in log houses, a comfortable climate is preserved there, and their environmental friendliness is good for health. In order to obtain all these effects upon completion of the building construction process, it is necessary to understand how to build a house correctly from a log house and what features it has.

Material selection: rounded log house or planed log

All log houses are divided into 2 types of buildings :

-

buildings of planed log , that is, those that were processed manually;

-

buildings that were built from rounded logs.

In order to understand how to build a house from a log correctly, it is necessary to have an idea not only about the external difference of the 1st warrant from the 2nd, but also about the constructive one.

"Wild Log House"

The history of architecture tells us that all the log houses that were built before the end of the 19th century were built from a "wild log house". This meant that the future building material was processed manually. A freshly sawn log was stripped of bark, while the bast layer should remain intact. It was he who protected the wood and its deep layers from moisture. This provided the log house with reliable protection against fungus and mold, and increased their "service" times.

The main feature of the house from the “wild log” was a bright and expressive form. Such individuality was given by non-cylindrical bars. A sawn log tends to taper from bottom to top. After wood processing tools such a difference in the size of the diameter still remained. The farther from the end, which was located at the roots - the thicker the log.

A tall tree can be processed and divided into several logs. Sometimes it makes 2 building elements, but the ideal would be to get 3 parts.

The classic rule for dividing a timber is as follows:

-

1 log - butt . This is the part that is located closer to the roots;

-

2 logs are different . This is the middle part of the wood;

-

3 timber - the third or the top . Accordingly - this is the last part of the log, which came to the top.

For the construction of the house, 1 part was used - butt. The frame in this place was the thickest, had high strength and the most minimal change in diameter. And in order to compensate for the differences that remained, the timber, when laying the walls, alternated: in one row the butt "looks" in one direction, in the next in the opposite direction.

But, despite such opportunities to simplify the construction of the house from chopped wood, it is worth a very careful approach to the selection of building materials. After all, you need to reproduce a flat and durable construction of logs of different diameters. And this is not a simple task.

The construction technology itself has hardly changed since that time. Houses are built in the same way: the “wild house” of different diameters is adjusted as close as possible to each other. It should be noted that the houses that are built in this way belong to the category of elite and differ in price. This is dictated by a certain complexity and laboriousness of the process. After all, after the construction of the frame, the house should stand from 1 to 2 years. During this period, he "sit down" in height to 10%. This factor should also be considered when designing. So apart from spending time and effort on the selection of building materials, it will take a lot of time and patience to see the result.

It might be interesting! B article on the following link read about the log house from a bar.

Round logs

Round logs are planed logs in industrial environments. On machines, the tree is brought to an ideal state: it becomes smooth and even along its entire length. On special machines in a bar all necessary grooves for fastening are cut. In this case, the dimensions are adjusted to the millimeter, which minimizes inconvenience in construction. Building a house with the help of such a frame is similar to the collection of the children's designer.

With all its convenience, a rounded frame has disadvantages. Ideal flatness in size and smoothness is achieved by removing several levels of wood.The production process also removes "useful" layers (sapwood) that protect the log from moisture, fungus and mold. Only the mature and sound central part of the tree remains. It is not protected from external factors. Under such conditions, it is necessary to additionally impregnate the timber with antiseptics, antifungal and antihelminthic drugs. The result is a beautiful and lightweight material for building a house. The downside is a low level of environmental friendliness and, oddly enough, durability.

Choice of material for construction

In order to properly to build a house from a rounded log, you need to know how to choose it and what material is more suitable in your area. Coniferous wood is most suitable for log houses. These are such trees as: pine, spruce, cedar and larch. But in the absence of desirable options on the market, you can use oak, ash, aspen and other hardwood. Spruce and pine are the most affordable in the price category. For this reason - the most popular.

When choosing this type of building material, the log house period is very important. It is necessary to choose a timber that was harvested in the winter. It is he who has the best moisture resistance.

A tree growing region is also important. If possible, stop your choice on wood in the northern regions. Such material is the most enduring. Good options: Baltic pine and Canadian spruce. The option of coniferous breed, which was properly prepared in compliance with all the conditions and requirements, is also very good from the central regions.

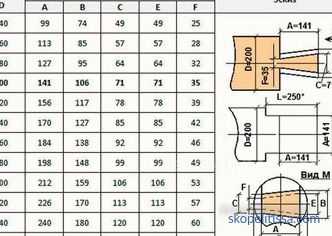

Please note that the choice of beam diameter depends not only on the design decision, but also on the climatic conditions. The main criterion is the maximum temperature in the winter season.

Recommendations for choosing a log according to temperature:

-

if in winter in your region not less than -20 degrees - you can stop at a diameter of 200 mm;

-

when winter a maximum of -30 degrees is 220 mm;

-

with a thermometer reading to -40 - choose a log that is not less than 240-260 mm and more.

It is also worth noting that by choosing a bar of a slightly larger diameter than that recommended according to the climatic zone, it perfectly compensates for temperature differences. The main thing - do not choose the material less than the specified. Despite the fact that the house will be warmed by means of laying a jute or flax-jute laying between the logs, it will not be able to give that comfortable temperature that the right size log can provide.

Additional criteria that you need to pay attention to when choosing a log house:

-

quality log yellow or dark yellow ;

-

on the cut there should be no stains;

-

good material the core is dark shade and takes 3/4 of the cut;

-

it is good when knots are missing, and if they are present, they should sit tight without gaps. The opposite picture indicates a damaged core;

-

the best ringing for a log is ringing. Try to strike the butt with an ax and listen to how it rings;

-

cracks are possible provided that their depth is no more than 1/3 of the logs;

-

the bar should not be twisted: such a log can only be used for laying the floor when building a house - for this purpose it is spread on planks and bars.

It may be interesting! In the article on the following link read about the house of the bar for shrinkage without finishing.

Construction technology

At first glance, all houses are built in the same way. But with careful study of this issue, certain nuances and features of construction come to light in one way or another. So the very and proper construction of the house of the log has its own distinctive characteristics.

Without knowing the technology of building a house, it is easy to make many mistakes. About them in the video:

Foundation

The main and most important element of any building is the foundation. Its depth and character depends on the soil on which the house will stand, on the nature of the walls' material and on the number of floors.

A log house is relatively light in weight.This quality of construction allows the foundation to be shallow. Virtually all variants of existing types of foundations are suitable for the construction of a log house. Often make a tape option. In case of difficult soils, a deep-laid foundation or pile foundation is performed. You can also make a slab option.

It should be noted that any variant of the foundation should go 300-400 mm into the ground. After it is poured and completely dried, it is necessary to conduct waterproofing (roofing felt with mastic). This is a very important process while the house is made from logs.

Walling

Upon completion of the laying of the foundation, they proceed to the main thing - the construction of walls. It is important to know that the first crown (the first row of logs) is never laid directly on the foundation. At first the "underlay" board is laid. It is made of linden timber with a thickness of 50-100 mm and a width of at least 150 mm. Already then proceed to the collection of walls with rounded log.

The first fixed rim should be cut from the bottom. Its end should be the same width as the baseboard. This is necessary for the house to firmly rest on the foundation.

Logs for walls are laid in circles (crowns). First put the logs that are parallel to each other. Then the other two sides, and placed on top insulation. It is attached to the log with the help of a construction steppler and should hang at the edges by 5 cm.

Then, the transverse sides of the house are laid, which will rest on the fixed rim. And we repeat the "procedure" collecting the house as a designer.

It can be interesting! In the article on the following link read about cottages from a bar.

Installation of the roof

The wooden house should not be left uncovered. After the last rim is installed, it is necessary to immediately proceed to the installation of the roof. When building walls from a tree, you can not lay the mauerlat (a special retaining beam for the rafters), but put the rafters immediately on the log. The recommended distance between the rafters is 600 mm. Such a gap will ensure the stability of the roof, and reduce the risk of its possible sagging.

Since wood belongs to "living" materials - the rafters must be fixed on sliding supports. Then pave waterproofing and after - crate. The pitch of the batten depends on the selected roofing material. At the end of the "cover" the house is selected finishing material.

It might be interesting! In the article next link read about polishing timber.

A caulk of a log house

A caulk of a house is a separate important stage in its construction. Upon completion of the construction of walls and roof, it is necessary to insulate the entire insulation, which was first laid between the logs, caulked inwards. To do this, using a special tool, the caulker wraps the hanging 5 cm of the gasket down and then pushes it in between the slits of the logs.

After completing the caulking iron and the roof, the house is left for a year to shrink. A year later caulk walls must be repeated. Some experts recommend to carry out the "procedure" again after a year of operating the house with the heating turned on.

Installation of doors, windows, installation of floors and floors

The important points when installing doors and windows is that they are installed only after complete shrinkage at home and only in special casing boxes that are installed in openings in the walls.

Such precautions are due to the fact that the tree is a “living” building material and another 5-7 years will fully sit down in size.

The floor is set on logs that crash into the first, and better into the second crown. The crown must be well ventilated in order to be subjected to rotting processes as little as possible.

After installing the entrance doors, windows and laying the floor, you can install a heating system, carry out communications, connect an electrician, as well as install interior doors, slopes, and plinths and put plumbing fixtures.

Wall decoration can be omitted. After all, the beauty of the log house is not only outside, but also inside. The bas-relief of slightly yellowish walls will fit into almost any interior. The main thing is to correctly emphasize the texture of the wood and add design with the necessary accessories. And your dream home is ready!

What a house can be made of a log house, see this video:

On our site you can familiarize yourself with the most popular projects before s made of logs from construction companies in the exhibition houses "low-rise country."

Conclusion

Despite the seeming simplicity of building houses from prepared round logs, there are quite a few pitfalls that only experienced specialists who know the technology can bypass. Therefore, the construction of the cottage should be entrusted to professionals who not only do everything quickly and efficiently, but also give a guarantee on their work.