Owners of slate roofs often face the need for continuous repair work on the roofing. The article describes the features of the repair of slate roof. The following material will acquaint you with the advantages and disadvantages of slate and the causes of surface defects. You will learn how to detect various types of defects, what popular ways to restore the roof of slate exist and how to prepare for the repair of the roof.

About the slate

Despite the variety of modern roofing materials in the private sector are still familiar gable roofs covered with slate. This material is in constant demand in the construction of residential houses, garden housing and outbuildings due to the following advantages:

-

Budget value . For the price of slate wins most roofing materials.

-

Long service life .

-

Easy installation and easy to machine.

-

Low thermal conductivity . Unlike sheeting or metal tile, slate coating on a sunny day heats up slightly.

-

Favorable physical properties . Slate is non-flammable, resistant to moisture, well absorbs noise during rain, hard enough to withstand the weight of a person.

Opponents of using slate coatings indicate the following disadvantages:

-

Composition . Slate sheets are made from a mixture of cement and asbestos fibers. Fibers increase the strength and fire resistance of the material, but at the same time, it is proven to harm human health (if asbestos dust gets into the respiratory tract).

-

Appearance . Over time, slate roofing tends to overgrow with moss. The deficiency is corrected by timely treatment with a primer; at the same time the hydrostability is also increased, and, hence, the service life of the coating.

-

Weight . Slate sheet weighs about 20 kg. For installation, you need a solid truss system and sufficient physical strength performers.

-

Fragility . The material is damaged quite easily and requires careful handling during transportation, installation and operation.

Causes of Defects

On roofs with gentle slopes, slate life is estimated at 15 years, with steep slopes it reaches a quarter of a century. But in practice it turns out that repairing a slate roof is required much earlier. The reason for most roofing defects is the low impact strength of the material. After the first ten years of operation, traces of time are visible on the asbestos-cement surface: chips, deformations and cracks, and sometimes holes. The inevitability of repair work is ensured by the following reasons:

-

Low quality of the material . This distinguishes the slate of handicraft production, the production of which was carried out with violations of the formulation of the mixture and technology.

-

Careless transportation and storage . Microcracks are difficult to detect, but they manifest themselves during assembly work - the sheet will crack when you first act or walk on it.

-

Shock loads . Mechanical stress is the most common cause of slate destruction. A gap or crack in the sheet may occur due to the impact of a falling branch, stone or hail.

-

Error selecting roof parameters . If a slope angle that is not suitable for this material is chosen for the roof, the sheets will experience excessive stress (until they crack).

-

Installation errors . The sheet may break or crack if you try to too hard to attach to the crate. The wrong choice of fasteners (for example, the use of nails without rubber gaskets) or inaccuracy in the manufacture of holes lead to the occurrence of cracks.

On our site you can find contacts of construction companies that offer the service roof repair. You can directly communicate with representatives by visiting the low-rise country exhibition.

-

Bioburst . The surface of the slate has a rough structure, on which any organic matter lingers, and over time mosses, molds and lichens settle. These uninvited green guests not only reduce the aesthetics of the roofing, but also successfully destroy it, penetrating into the surface layer.

-

Weather and time . Slate maintains 25-30 cycles of a freezing thawing without change of operational characteristics. After that, the strength and water resistance begins to gradually decrease.

Types of defects and how to detect them

All these troubles will sooner or later lead to the need to repair the roof of slate. The main problem is the timely detection of defects (usually cracks), which is not difficult in the case of a smooth metal roof, but difficult on the rough non-uniform surface of the slate. The leaks that were not detected in time open the way to moisture in the under-roof space, the insulation is soaked with water and ceases to perform its functions, the roof system suffers, and you will have to repair it seriously.

On our site you can find contacts of construction companies that offer the service of completing unfinished houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

A slate roof (especially after long service) requires careful attention. Experts recommend inspecting the roofing space after each shower. The presence of a problem at the very beginning may indicate the smell of dampness. The first visible sign is the appearance of a mold spot, which clearly indicates the location of the leak. If the cracks are not visible from the inside, you can additionally inspect the place where the sheets join with slate nails using a flashlight. Cracks on the slate surface need different repairs, damage can be classified as follows:

-

A small crack in the upper (protruding) wave . Such a defect often occurs after severe frosts. It is easiest to notice during an external examination, because under such minor damage the water does not stagnate, and leakage is observed only after heavy rain. This is the most innocuous defect that can be easily corrected.

On our site you can find contacts of construction companies that offer the service of reconstruction and reconstruction of houses. You can directly communicate with representatives by visiting the low-rise country exhibition.

-

Crack in the lower wave . The defect usually leads to leaks, since the bottom point is where the moisture constantly stagnates. The main problem during repair is to achieve the necessary tightness.

-

Crack across the wave . The most unpleasant option, difficult to repair and with long-term consequences - such cracks tend to expand, capturing the neighboring waves.

-

Significant crack or breach . The result of a missed small crack, severe mechanical damage or careless walking. The older the roofing, the easier they arise.

-

Chip . The usual place of occurrence of chips - the edge of the roof, the reason - icicles, especially snowy winter or unsuccessfully fallen branch.

-

Moss . Harmless, at first glance, the plant is able to turn a sheet of slate into dust, which will result in a major overhaul with the appropriate budget. It is much more practical and cheaper to take care of the problem on time (as in other cases).

About the sealing of cracks on the roof of the garage in the following video:

Types of repair

Despite the fact that slate roofing is characterized by low resistance to damage, the majority is easily corrected by local repair and insignificant monetary expenditure. In general, the repair of a slate roof according to the degree of intervention is divided into three types:

-

Small . It successfully copes with minor defects, cracks or minor holes. In such works, modern sealants and bitumen mastics have proven themselves well.

-

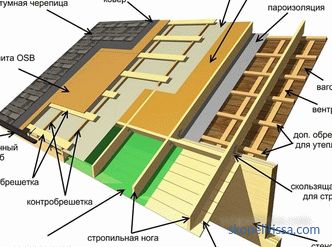

Partial . In some cases (large break, long transverse crack), replacement of a damaged sheet is inevitable. It is easy to make it - the slate roof is a serviceable design that allows the replacement of individual sheets. Along the way, you can check (and, if necessary, improve) the state of the layers of hydro and thermal insulation.

-

Capital . It is carried out with extensive faults caused most often by the venerable age of the roof. Usually, it is accompanied not only by replacing the slate coating, but also by leveling the base, by completely or partially replacing the truss elements.

It might be interesting! In the article follow this link read about the insulation of the roof from the inside with mineral wool.

Preparing for repair

Before starting work, it is necessary to carry out preparation, which consists of the following measures:

-

Surface preparation . The roof is thoroughly cleaned of debris, soil and any organic matter; Additionally, a hard bristled brush is used to treat cracked areas.After mechanical cleaning, the slopes are doused with a stream of water from a hose and allowed to dry.

-

Comfort of work . For support use a ladder, a board with bars stuffed across or a ladder, helping to evenly distribute the load. They wear rubber boots on their feet, which will help you to sit comfortably and safely near the problem sheet and not to push the neighboring ones.

-

Safety of work . The specificity of slate makes care about the protection of respiratory organs. The best option would be a respirator, in the absence of which you can use a gauze bandage (glasses will also be useful).

About repairing slate with bitumen mastic in the following video:

9 ways to repair

In practice Various technologies and materials are used to repair slate coatings; the most common methods include the following methods:

-

Using bitumen resin . Pitch, heated to 150 °, fill the gap; after drying, the resin forms a hydro-protective film. Such work requires a professional approach, taking into account the toxicity of fumes and the temperature of the repair composition.

-

Using a bituminous sealant . Bituminous sealant forms a non-shrinkable seam and provides long-term waterproof sealing and sealing of cracks. The material has excellent adhesion (adhesion) even with a wet surface; Available in banks and tubes (which is somewhat more expensive, but much more convenient).

-

Tape for Slate Roof Repair . The self-adhesive tape on a bitumen basis is simple in work and provides instant sealing. One side of the material is covered with a bitumen layer, protected by a film (removed before work), the other side is laminated with aluminum foil. The tape is resistant to changes in humidity and temperature and long (15-20 years) service life.

-

Cement based mixtures . The cement mortar composition is close to asbestos cement slate, which allows to obtain a solid seal. Cement mixtures are prepared immediately before use, there are various recipes. Repair of slate can be carried out with a mixture of cement and liquid glass, or cement and sand with the addition of adhesive for tiles (PVA). A common solution of a mixture of cement, tile adhesive and asbestos (in this case, you should worry about personal safety and stock up on a respirator). Initially, these methods were widespread, but with the advent of modern and effective waterproofing tools are gradually receding into the past.

It might be interesting! In the article next link read about the device and installation of an interception mesh.

-

A mixture of drying oil and chalk . Budget folk remedy - the crack is filled with the prepared mixture, and after drying it is masked with oil paint. The method has a significant disadvantage - due to the heating of the sun rays, the ductility of the drying oil decreases, the seam can lose tightness.

-

Ready putty . Used mixtures with waterproofing additives in the composition. To waterproofing turned out quality, work carried out in dry cloudy weather. The repair turns out to be multi-layered: a mixture is applied to the crack, after some time glass yoke is laid on top, which is covered with a second layer of putty.

-

Rolled roofing material . Bituminous coating, which is intended for the arrangement of a soft roof, is well suited for the repair of slate. A piece of membrane of the desired size with a heated back is superimposed on the cleaned and defatted place with a defect. To warm up use small cylinders with a roof gas burner.

About washing high-pressure slate in the following video:

-

Latka . If the gap in the roof is too big to be sealed with mortar or taped, use a patch of slate sheet. It is applied to a sheet with a defect, pre-treated with a sealant (glue or hot bitumen). The patch can be cut not only from the asbestos-cement sheet, but also from ondulin (polymer slate) or corrugated (if the wave corresponds).

-

Cleaning from moss . Combating insidious vegetation with a hard brush is inefficient, and the risk of damaging the roof increases to such an extent that it requires major repairs. Manufacturers offer sprays for the destruction and prevention of the appearance of moss, lichen and mold. The liquid is sprayed on the contaminated surface, after a few hours all the organic matter is removed with a brush with water. So that the moss does not appear again, the roof is primed and coated with weather-resistant acrylic paint.

-

Replacing sheets .It is performed if the previous methods fail to cope with numerous damages. To replace the sheets will require a team of 2-3 people - the material is heavy and requires careful handling, which alone is difficult to ensure.

It might be interesting! In the article on the following link read about a house with a through view in Holland.

Conclusion

If cracks appear simultaneously in different parts of the roof, this almost certainly indicates that the installation was carried out without complying with the technology. In this case, the process of destruction caused by the internal stresses of the material will continue, and it cannot be stopped by conventional methods. To remove the load, it is recommended to drill a hole in the crack, fix it with a self-tapping screw and process the edges with a sealant. Periodic (once per season) inspection of the slate roof, attentive care and preventive measures will help extend the life of this unpretentious roofing material.

Rate this article, we tried for you