The rafter system of a gable roof is considered to be one of the simplest in a purely constructive manner. It consists of only a few elements, the number of which decreases or increases due to the size of the roof itself. But with seeming simplicity, the process of erecting a gable roof itself requires knowledge of some nuances that affect the quality of the final result.

What is a gable roof

From the name it becomes clear that the design Roofs are two slopes that have a rectangular shape in the plane. More often, the slopes have the same dimensions, but there are so-called asymmetrical structures, in which the slopes differ in size from each other.

At the same time, the slopes are set to each other at a certain angle, which is called the slope. The line of contact is the ridge bar, which is part of the truss system. Simply called the ridge, and it is the highest point of the roof.

The side planes formed by slopes are called gables. They have a triangular shape. After the construction of the roof, the sidewall is veneered with sheet or panel materials: plywood, OSB, even boards and so on.

What is the rafter system of a gable roof

The basis of the construction of the slopes are the rafter legs, they are also rafters. They are made either from sawn timber (beams, planks), or from a steel profile (corner, channel). In the private housing construction used wood. It is easier to work with it, plus lumber is cheaper.

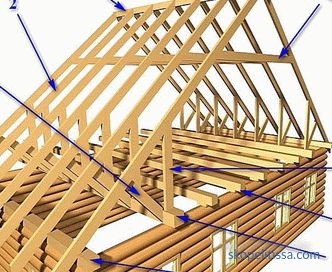

The device for a truss gable roof system is not only rafters. In addition to them, there are several more mandatory elements. In the photo below all the elements of the gable roof are shown. We denote them.

Elements of the roof system of the gable roof

-

Mauerlat . In fact, this is a beam on which the rafters rest. Its purpose is to evenly distribute the load from the rafters to the walls of the house. If the mauerlat is not used, then the rafters will press on the walls to a point, that is, large stresses will arise at the installation sites, which will lead to cracking of the walls.

-

The rafters are installed at an angle.

-

Fad , it is also a ridge cant or girder. His task is to form a place for joining rafter legs. The ridge bar is an optional element of the gable roof. There are designs in which it is not installed. But about it is slightly lower.

-

Tightening . They are not always used, but only on hanging rafters, or if the rafter system is installed on a wide house.

-

The ceiling beams that form the ceiling in the room and the floor in the attic.

-

One of the floor beams, which is called , is lying . It additionally performs the functions of a base for support posts that support rafters. Not always used.

-

Support pillars , they are the headstocks supporting rafter legs. They are set only if the length of the span of the house is at least 6 m.

-

The struts , they are also diagonal supports. They are used only if the support stands cannot provide the overall reliability of the truss system.

There is another element that is clearly visible in the photo below. These are support racks for ridge run. They are installed if the construction of the truss system is heavy. That is, the entire structure is assembled under a heavy roofing material, for example, under a ceramic tile.

It might be interesting for you! Warm roof - This is an important detail in the construction of energy-efficient homes. From the article on the following link you can learn how to properly insulate the roof of the house.

Types of rafters

The rafter system of the roof (gable) can be assembled from laminated rafters or hanging.

Suspended

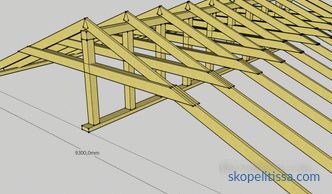

They received their name because they rest against their lower ends on the walls of the house, the upper ends on the ridge girder. In this case, the trusses are subjected to loads that bend them. The design is reliable, durable, with a large bearing capacity.

In the photo above, the rafter system of the slant type is shown. It is clearly seen that the legs rest on the top of the horse. In this case, there are two types of fastening of the rafters themselves in the upper part:

-

fastening is made to the ridge:

-

fastening is done between themselves with an emphasis on the ridge ( photo above).

Hanging

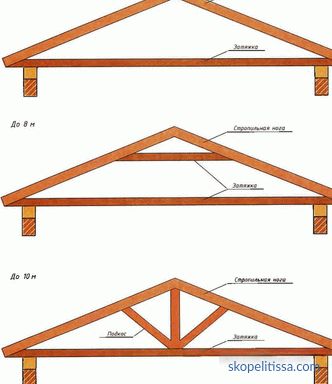

It is necessary to immediately indicate that this type of roof system can be used if the distance between the walls of the house does not exceed 12 m.Because the rafters rest against the lower ends on the walls, and the upper ends only between themselves (the ridge girder is absent in the construction). Hence, the low carrying capacity with a large spread.

Hanging rafters for the roof have one purely constructive disadvantage - a large bearing load on the walls of the house. To reduce it, set the inhale between the legs, to get a hard triangle. Often, the functions of puffs perform bearing beams overlap.

If necessary, reinforce the hanging rafters, install racks and struts under them.

Installation of the truss system of the gable roof

Two types of truss system define two types of technology their assembly. Consider each separately.

Installation of overhead rafters

There is a certain sequence of assembly of the rafters.

-

Two extreme support posts for the ridge bar are installed. They will not only support the timber, but also be elements that form the pediments of the building. Attach them at the bottom to the mauerlat. At the same time strictly put vertically, and the upper ends in the same horizontal plane. To do this, they stretch a strong thread between the posts, with a level checking it for horizontal position. If there are deviations, then one of the supports (low) is raised with the help of wooden supports.

-

Horizontally stretched yarns are used to mount intermediate support posts with a step of 2-2.5 m. To keep the bars of the posts not moving, they are supported by temporary fasteners: props or puffs.

-

A ridge beam is placed on the stands, which is fastened to them.

-

It is made in pairs installation of the gable roof trusses . Installation can be started from any side. Fastening is immediately carried out to the mauerlat and to the ridge. The main thing is to maintain the distance between the legs, which is determined depending on the severity and bearing capacity of the roofing material. Usually in the project of the house this parameter is indicated.

-

If there is a need, intermediate support posts and struts are mounted.

Mounting the hanging rafters

Technology The installation of hanging rafters is different. For this, the entire structure, assembled from two trusses and puffs, is assembled on the ground. That is, roofing trusses are prepared in the required amount, which are then raised to the roof. Sometimes craftsmen collect farms on the roof. Collected one - installed, collected the next.

It should be noted that such farms have a significant mass. It is difficult and dangerous to lift them manually, so they use the services of a crane. And this increases the cost of construction.

The most difficult thing is to set up trusses. All of them are installed at the place of installation with a planned step, where they are temporarily fixed with trusses and struts. Then the thread stretches between the farms. It must be set so that, firstly, it is stretched strictly along the horizon, and secondly, according to the construction, which is higher than the others.

It remains only to raise the trusses, which were below the stretched level. And the last - installation of the batten, which will fix all the trusses in one truss system. Please note that at the bottom of the rafter will be fixed to the power plate.

This may interest you! When the installation of the truss system is completed, the turn of the roofing works comes. From the article on the following link you can learn how to cover the roof of the house.

Calculation of rafters

What parameters need to be calculated so that the roof of the house was assembled exactly according to the project:

-

length of rafter legs;

-

step of their installation;

-

section of the used timber.

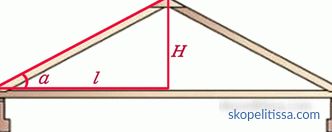

With the length, everything is simple, for this you have to use the Pythagorean theorem, which is based on the formula: c 2 = a 2 + b 2 , where c is the hypotenuse of the triangle (these are rafters), a and b are the legs. The latter is the height of the roof and half the width of the house. All parameters can be easily measured.

With an installation step more difficult, because a lot will depend on the mass of the roofing material and the loads from natural precipitation. The more both the load, the smaller the installation step. But, as practice shows, this parameter varies from 60 cm to 2 m. The last indicator is used if corrugated flooring with large parameters of corrugations is used as the roofing material, for example, H75.

As regards the cross section of truss legs, here, as in the case with the installation step, the loads are taken into account, as well as the length of the legs and the step of their installation. Here, the relationship is as follows: the greater the load, the step and the length, the larger the section.

In the video installation process truss system:

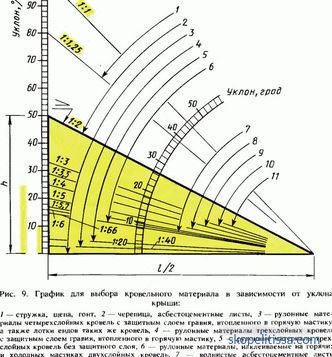

And one more thing. Rafters for a gable roof stacked at a certain angle (in the photo marked with the letter "a"). The slope is selected with the calculation of the choice of roofing material. That is, some coatings can not be laid on the roof, if the angle is less than the required. Here are a few relationships:

-

the minimum angle of the truss system for slate is 22 °;

-

for sheeting is 12 °;

-

for metal tile - 14 °;

-

soft tile - 15 °.

On our website you can find contacts of construction companies, which offer service of design and repair of a turnkey roof. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Summary of the topic

Gable roofs are traditional structures. But from the article it becomes clear that there are two truss systems that form the basis for the construction of roofs. Choose the one that fits the size of the house. As a selection criterion, the loads pressing on them are also taken into account. Therefore, it is important to relate everything correctly, given the nuances of construction processes.