In modern country life, a bath is an important component of a harmonious existence and respect for your health. The opportunity to relax in your own bath is a pleasure that is hard to give up and which depends entirely on the stove.

Already a thousand years ago, different peoples existed differences between baths and methods of taking bath procedures. A few centuries ago, the most common Russian bath was a black-style (chicken) bath, made of stone or clay. The brick was then expensive material - it was made by hand and was affordable only to very wealthy people. A massive brick brick stove began to appear with the development of industrial production methods (and cheaper) of this material.

Bath stoves: features and characteristics

Bath helps to get rid of from negative emotions and is often associated with healthy rest, good spirits and cozy atmosphere. The stove is the heart of the bath; comfort, steam quality and safety depend on its characteristics. The main attribute of the bath is not so easy to choose, there are too many selection criteria and requirements for it. And if the owner decided to build a bath, he will have to deal with several issues: to decide on the material and design of the furnace, to consider its size and type of fuel.

Today, few people except professional stove-makers know that the method of erection and the principle of operation of a sauna stove is different from the functioning of the oven on which food is prepared. Brick bath stove - the continuation of the traditions of the ancestors, which has the following features:

-

Construction . The main parts are: firebox, chimney, grate (place for fuel) and ashpit (chamber where ash is accumulated).

-

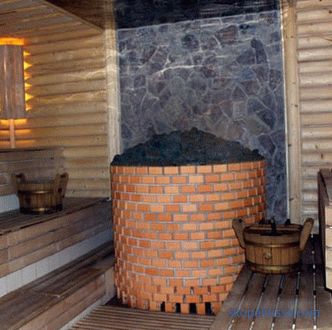

Characteristic . Kamenka, a container for stones, which is closed and open. Stones are used as heat accumulator, which increases the time of bath procedures.

-

Weight . It can reach 1000-1200 kg (depending on the size of the stove). For such a massive structure equip a solid foundation.

-

Fuel . Firewood is used for the firebox, but the stove can work on electricity and gas.

Brick stoves are determined by two main parameters:

-

Dimensions . The size depends on the area of the premises that are planned to be heated. The most common are furnaces with a base area of 3.5x4 bricks (890x1020 mm) or 4x5 bricks (1020x1290 mm). If you do not take into account the chimney, the construction height is 1680 mm (or 2100 mm, if the ceiling of the steam room is high).

-

Construction . The owners prefer to install a model with a water circuit, which serves as a tank for heating water. The tank may have an upper (near the chimney) or lower (near the firebox) location.

The advantages and disadvantages of a brick kiln

No matter how profitable and easy to use are the metal furnaces, the owners, who are wise with everyday experience, prefer proven brickwork. Brick bath stove has the following advantages:

-

Heat capacity . The stove is capable of keeping heat for 6-8 hours and warming up several rooms (depending on location).

-

Energy independence . A wood burning stove is ideal if there is no gasification and there are interruptions in electricity.

-

Operating savings . No need to let the gas pipe or pull the wiring, and then pay the bills. Firewood will be much cheaper (especially if you harvest them yourself).

-

Comfort . Such furnaces produce saturated, but not scalding (light) steam and soft heat. The atmosphere of the steam room does not make breathing difficult and is ideal for lovers of steam often and with taste.

-

Environmentally friendly . Both the brick from which the furnace is built, and firewood are environmentally friendly materials that are safe for health.

-

Design . There are real masterpieces of furnace art with stunning architecture and design.

-

Fire Safety . It is provided with design features that fully comply with JS 7. 13130-2013.

Brick kilns lose to other structures due to flaws:

-

Difficulties in the performance of . The laying process has nuances, and it is not easy to find a competent stove-maker.

-

Size . A large stove eats up precious steam room area.

-

Price .Brick pleasure is expensive: it is necessary to equip the foundation, purchase high-quality brick and pay for the services of the master.

-

Time . The furnace is melted, and the steam room warms up for a long time.

-

Care . Requires systematic cleaning of the ash pan and periodic - the chimney.

On our website you can read the most popular bath projects from construction companies, presented at the exhibition "Low-Rise Country" houses.

Safety of the project

The brick stove requires competent insulation from wooden surfaces - a rule that sometimes breaks down with a fire. In order for bath procedures to be safe, several conditions must be met:

-

Foundation . You need a reliable foundation, which is equipped according to certain rules.

-

Chimney . The pipe passes through the ceiling, ceiling elements and roof. When arranging the chimney, it is necessary not only to protect adjacent surfaces from heating, but also to preserve the tightness of the steam room. The pipe is separated from all elements of the building with a gap filled with a layer of refractory material.

-

Furnace location . The general rule is that wooden walls should be protected from heat. Therefore, there are minimum permitted distances: between the side surfaces of the furnace and the walls - 50 cm, between the furnace door and the opposite wall - 150 cm.

-

Insulation . The wall behind the stove is protected by brickwork and metal sheets. A metal sheet (10 mm thick) is placed on the floor in front of the firebox, a protective measure against embers ejected from the flame.

Materials for the furnace: which and how much

For masonry suitable brick, able to withstand multiple temperature extremes. There are two fairly strong, fire-resistant brick forks:

-

Fireclay bricks . Heat-resistant cream-yellowish material that can withstand heat up to 1,400 ° C, without loss of strength. Such a brick, without harming itself, accumulates heat and at the same time has a high thermal inertia (it slowly heats up and cools down). In terms of parameters, it surpasses other varieties, but also costs more, which is why it is mainly used for laying out the firebox (20-30 pieces are required).

-

Full-bodied red brick marked M (at least M150). From it lay out the body, chimney and decorative elements. For a modest construction, 250-280 bricks may be enough, for a large project you will need 800 (or even 1000) ceramic bricks.

On our website You can find contacts of construction companies that offer the service of building and designing baths. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

In addition to bricks, other materials and tools will be needed:

-

Masonry mortar . It consists only of clay and sand. For it does not use cement, which crumbles when heated and over time causes the destruction of the masonry.

-

Furnace casting . Cast iron doors, steel tanks for water and stones, a grate (grate), a view (a furnace damper) are used.

-

Heat insulator . Any material that can withstand temperatures up to 1200 ° C is suitable - for example, basalt wool in thin sheets.

-

Tools . Need trowels, tape measure and building level.

About the stove with a fire box in the rest room in the following video:

Kamenka is a feature of the stove for a Russian bath

The main attribute of a bathhouse is often classified by the method of the firebox:

-

First came the furnaces that were fired in black . They did not have a chimney, and while the logs were burning, the smoke was going indoors and the ink of the wall was soot. After that, the smoke was released through the window, and in order to steam it, you had to wait until the fire was completely burned out. Heat and steam were obtained from heated stones lying in the hearth, a type of stove.

-

Furnaces that are fired gray or white have a chimney and a stove in their construction. The bath is gray-gray (with an open stove) warms up faster, but soot also accumulates on the stones, and this means that you have to wait for the complete burning of firewood.

-

In a white-bath bath, the stove is equipped with a closed heater. It does not pollute the walls of the steam room, does not burn oxygen and carefully preserves heat for a long time. If steam comes out of an open stove hard, burning, then here it remains comfortable, soft, even if the thermometer shows 100 ° C.

On our site you can find contacts of construction companies that offer the service of installing fireplaces and stoves. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Stoves for a bath can be conveniently divided by the method of the firebox:

-

Periodic operation . Here, the stones are on the grate above the flame, have maximum contact with it. Water on the stones can only be poured after the firewood has been burned out (otherwise you risk pouring the flame). The stove has to be heated periodically

-

Permanent (continuous) action . The stones are in a closed stove (insulated metal tank), which is heated by fire. Heat transfer suffers a little, but pouring water and heating is allowed all the time (permanently), and soot stays inside and does not pollute the steam room. The stove is heated when people are in the room; its design does not allow the products of combustion to get into the steam room.

The stove design is responsible for generating that very famous “light steam”, the optimum temperature (70 ° C) and humidity (60%). It is best to cope with this task stoves with a closed (internal) heater.

About the furnace with a water tank in the following video:

Of course, a stove with a pile of stones on top looks much more effective and the steam seems to produce excellent. In fact, an open sauna stove is more suitable for a Finnish sauna, with its high temperature and dry air (the Finns pour water a little). High temperatures and high humidity can cause heart problems in an unprepared person. The main benefit of the open heater (as well as the metal stove) is the rapid heating of the room.

Erection of a brick-built sauna stove: a sequence of works

Each brick stove for a bath is a piece of production. Regardless of which configuration is chosen, the furnace is being built in the established order, from the foundation to the chimney and finishing. The main task is to ensure that it does not smoke and effectively heated the steam room.

Planning

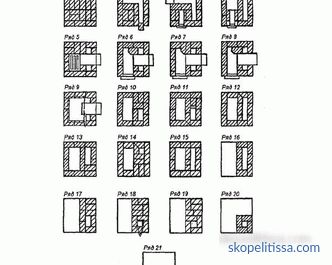

The stove project (size and configuration features) is selected in advance, simultaneously with the drafting of the bath. After the project is selected, an order is drawn up - a plan showing the layout of bricks for each layer (row) separately.

It might be interesting! In the article on the following link read about wood stoves for the house.

Foundation

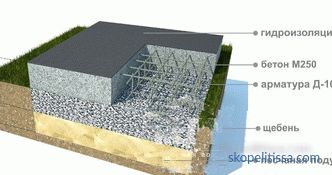

Even a modest-sized stove weighs about 800 kg; The weight of a solid construction for a large steam room easily goes over a ton. It is clear that such a unit must rest on a solid foundation, for which certain requirements are met:

-

The place under the furnace is better to choose before construction, otherwise you will have to cut the carrier beams and floor logs for the base arrangement and the truss system to remove the pipe.

-

The oven foundation is more practical to do unrelated to the base of the bath ; This will help protect the building if it suddenly begins to shrink. The bases should not touch, even if the stove is located near the outer wall. In this case, a gap is made between the bases (at least 5 cm), which is filled with thermal insulation.

-

The foundations for the bath and the stove are laid at one depth , but not less than the depth of soil freezing (in the European part of Russia the value is 70-80 cm). If the soil is dense, 40-50 cm is enough.

-

The correct foundation looks as an inverted trapezoid - the lower base (in the pit) coincides with the size of the stove (for example, 90x95 cm ), the top one is made 10-12 cm more on all sides (it turns out not less than 100x105 cm).

Preparation of the

solution The tradition involves performing laying on a clay-sand mixture, without the use of cement that does not tolerate high temperatures. In order to improve the quality of the masonry, make the following preparations:

-

The clay before use is soaked for a day . The best quality is obtained when using red or chamotte clay - then the thermal expansion of materials will coincide.

-

Sand is sieved to remove impurities and make the mixture homogeneous.

The quality and life of the stove depends on the thickness of the masonry joint. The ideal value is 0.5 cm; increasing or decreasing this value reduces service life.

About the detailed process of laying the stove in the following video:

Laying

When the clay solution is ready, proceed to the laying.It is recommended to start with the construction of a brick wall that protects the adjacent wall from critical heating. The laying of stoves for a bath is carried out in compliance with the following rules:

-

Before starting work, printed order are stored.

-

Bricks are stacked according to plan ; casting is inserted as necessary.

-

Experienced stoves prefer to stack each row first "on dry" , without solution. Such a preliminary fitting significantly improves the process and avoids difficult mistakes. The method makes it possible to accurately select bricks and try on casting.

-

Formation of the first row . An important stage on which the geometry of the furnace depends. At the end of the row, check the corners.

-

Housing installation . The second row (and subsequent ones) is laid with an offset, so that each seam falls on the middle of the brick from the previous row. Such a chess order ensures the reliability of the design.

is used for masonry of the furnace part! It can be interesting! In the article on the following link read about stove heating.

-

Masonry of the firebox . For it, use a refractory (chamotte) brick and prepare a special solution on chamotte clay (you can buy ready-made). The fire chamber is erected simultaneously with the walls of the hull (with which it is not connected) and smoke channels. In order to increase the burning temperature (to reduce thermal conductivity), a layer of heat-resistant thermal insulation is sometimes placed in the gap.

-

When laying out bricks check with the scheme so as not to miss the details - the formation of the blowing chamber, the place for the door and the grate, the laying of the chimney channel and the construction of the chimney pipe ).

-

During work, you must regularly check the thickness of the seams , as well as the verticality of the walls; it will save the furnace from distortions and cracks.

Water heating tank

Most often in the project is planned water tank is convenient and economical. The place for its installation is chosen so that it can absorb the maximum amount of heat. The tank can be mounted or built-in, depending on the size of the stove, and is installed near the flue duct.

The volume of the tank is calculated on the basis that a reserve of 20-25 liters of hot water is required per adult. If the bath is planned for use by the company, it will be more practical to install a tank with a capacity of 100 liters or more. To prevent the water from turning yellow, choose a stainless steel tank.

Drying the oven

After the oven is finished, it is allowed to dry for 2-4 days (size affects the duration). Then, in a sparing mode, a test firebox is carried out - the furnace is heated with chips and straw, which additionally dries the structure. There may be several such pre-furnaces — until the damper stops staying wet from the night.

About Kuznetsov’s sauna stove

The team led by Igor Viktorovich Kuznetsova developed a fundamentally new design of a stove with a two-tier cap - a chamber in which heating takes place (in the lower cap) and separation of the movement of hot and cold gases (in the upper one). Hot gases are trapped in the furnace, which significantly increases the heat transfer of the structure.

A Kuznetsov brick oven can maintain a suitable temperature regime not only in the steam room, but also in the washing room and in the rest room. High efficiency, economical fuel consumption and a minimum amount of soot during combustion contribute to the popularity of the design.

Brick kiln: facing features

Brick kilns are suitable for facing like no other Since the brick and cladding have an approximately equal coefficient of thermal expansion, which cannot be said about the metal construction. The brick oven heats up gradually, and the lining manages to warm up evenly. The most popular cladding materials are:

-

Clinker tiles . Clinker has a high refractoriness and heat capacity, it does not deform over time and gives a cozy look to the steam room. In the production of clinker knead dyes and chamotte clay.

-

Terracotta . Extruded pressed clay, subjected to roasting. The tile has a characteristic red-brown color and excellent strength.

-

Maiolica . Tile material obtained by pressing; an improved version of terracotta. A colored pattern is applied to the tile and coated with glaze.

-

Tile (a type of tile).A special box-shaped tile, often hand-made, decorated with a subtle pattern and covered with glaze, was originally designed for lining furnaces. The tiles have a special design of the back side and are fastened with special metal pins to the seams, simultaneously with the stove laying.

It might be interesting! In the article on the following link read about installing a stove in a bath.

Conclusion

Of course, building a traditional stove for a bath is troublesome, expensive and time consuming. It is difficult to find a stove master who can competently (according to your wishes) pick up and deliver the stove with maximum heat output and economical fuel consumption. Despite all the difficulties associated with the construction, brick construction does not lose its popularity. Connoisseurs of the bathing business appreciate the stove because it is able to develop the best lightweight steam, create an atmosphere of complete relaxation, unattainable for all other stoves.