Experts quite ambiguously refer to the option of warming the house from the inside of the walls. Most often, this method is considered as an alternative, if for some reason there is no possibility to warm the house outside. In any case, to warm the house from the inside is not recommended without the necessary qualifications. If there is no clear understanding of how to insulate the walls of the house from the inside, errors in choosing insulation and vapor barrier materials are guaranteed to lead to the constant formation of condensate, which will cause the spread of fungus and mold in the walls.

is attached to its lags

Correct internal insulation principles Correct the choice of thermal conductivity of insulation makes the work on internal insulation as effective as the creation of an external thermal interlayer, provided that the heat barrier is properly positioned.

Not every heat insulating material is suitable for warming a house from the inside of a room. Certain properties must comply with it in order to ensure the assigned tasks:

-

Low permeability.

-

Lack of secretions harmful to human health.

-

Watertight.

-

Ability to hold the configuration under mechanical loads.

It is important to know! The vapor permeability of insulating materials should go to a decrease in performance, that is, the insulation must provide a more reliable protection for steam than the wall. This design ensures the free flow of moist air through the wall thickness to the outside.

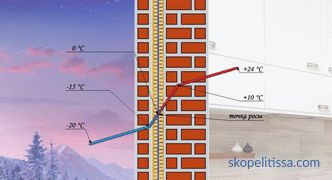

To avoid problems of warming from the inside, first of all, you need to determine the location of the dew point. Its correct position should be in the wall or insulation, but not at the junction between them.

If this happens, moisture accumulation is inevitable and, as a result, rotting, mold and fungus on the surface . This situation is possible due to the large thickness of the insulation, since it creates a complete insulation of the wall from the internal heat.

It also happens as a result of low vapor permeability. Particularly prone to this phenomenon are walls of bricks and concrete. In this regard, the internal insulation in such houses is justified only in non-alternative options.

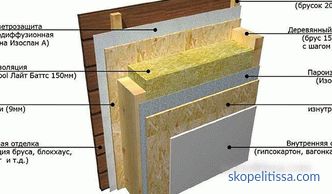

But in a building made of lumber or logs, such a layer of insulation is quite allowed, you just need to maintain a gap between the wall and the insulation. Therefore, in order to withstand all the requirements for internal insulation, on the wall, you must first make a frame of a vertically positioned beam to the width of the insulation size.

Then a waterproofing film is spread and fixed along the wall and a material for insulation is placed between the slats. It, in turn, is fixed by transverse strips and then the vapor barrier film is tensioned from above.

Types of materials and selection criteria

In order to to avoid problems during the further operation of the house, you need to choose the right insulation. In addition to physical properties, it also has mechanical parameters. Within this feature, the following materials for wall insulation inside the house are determined:

-

Mineral wool - the product produced in rolls is produced in different thicknesses.

-

Bulk insulation l - the material in the form of granules from the foam, has a different configuration and size.

-

Foam blocks - insulation, which includes foamed concrete, sand, bone glue and pine rosin.

-

plates - the insulating material in the form of plates, which are made by pressing and gluing, have a different size and thickness.

On our site you can find contacts of construction companies that offer house insulation service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Criteria for choosing

Before insulating the walls from the inside in a private house, it is necessary to get acquainted with the parameters by which these materials are divided. First of all, you need to know its following features:

-

Thermal Conductivity . It should be low enough.

-

Mass . Lightweight products do not require additional mounting.

-

Vapor permeability . The higher such a property of a material, the more effective its application, since it penetrates less moisture, and the walls remain more dry.

-

Possibility for further finishing .

And also, it should have a long service life, allowing to replace no more than once every 12-14 years.

The use of mineral wool

The technical characteristics of this material today make it one of the most popular insulants. Its main advantage is its low cost and low degree of thermal conductivity.

And also indisputable advantage of mineral wool is its versatility. It can be applied to any uneven surfaces of any shape: roofs, ceilings, non-standard openings in the walls.

Divide the mineral wool into three types:

-

Basalt.

-

Slag.

-

Glass Wool.

All the varieties of this heater are united by one property: thanks to the interlacing of fibers among themselves, air spaces are formed inside of it, providing a low level of thermal conductivity.

This is important! Minvat easily absorbs moisture, so it is recommended to use it as a heater inside the house only in addition to the outer insulating layer.

We insulate the walls from the inside with expanded polystyrene

When choosing between mineral wool and expanded polystyrene, you need to keep in mind one thing. This insulation has a low vapor permeability, so it is not recommended to use it on walls with high vapor permeability (timber, log, porous concrete).

It will be more effective to use it for thermal insulation of walls made of brick, blocks with low moisture permeability. For gluing this material used adhesive mixture.

When fixing insulation, except for glue, use special nails with caps.

Installation of plates is carried out sequentially in several stages:

-

The surface is being prepared. Cleared, primed and marked by lighthouses.

-

A rail is fixed at the bottom for supporting PPP sheets so that there is no displacement during the connection.

-

Apply glue to the surface of the wall and the plane of expanded polystyrene.

-

They lay, level and glue insulating sheets. It is recommended to do this some time after applying the adhesive.

-

The plates are additionally fastened with nails. Hammer them in so that the caps are slightly drowned in expanded polystyrene.

-

Then, a grid is applied to the plates, and the surface is treated with a plaster mortar with a final rubbing. After drying, the panels are ready for further finishing: painting or wallpapering.

Note! In spite of the fact that internal insulation is positioned as an alternative to outdoor in bad weather conditions, it is recommended to warm the walls inside the house in the summer with heated partitions and in the absence of precipitation.

Obviously about the choice of insulation, see the following video:

It might be interesting! In the article the following link read about how and how to warm the foundation of the house outside.

Penoplex is an environmentally friendly material for insulation

This heat insulator is a demanded modern insulation that exceeds the quality of the foam. This granulated blend of polystyrene has many advantages:

-

water resistant;

-

fireproof;

-

environmentally friendly material;

-

neutral to chemical effects;

-

ideal noise insulator;

-

light weight.

Excellently manifested itself at the time of mechanical loads and at low temperatures.

Work steps

First of all, before internal warming the walls of the house it is important to know that the dew point will change - the place where the humid air enters a state of condensation.

Consequently, if you choose the wrong material, or its thickness, then such insulation can deteriorate the condition of the walls: a mold, fungus, destruction of the partition will appear.

This is important! It is better to entrust all calculations for choosing insulation, as well as carrying out installation work, in order to avoid irreparable mistakes, to experts from a proven construction company.

Before starting work on wall insulation, it is necessary to follow certain rules:

-

Remove old coatings to the base of the surface, clean, remove possible formation of mold or fungus.

-

Treat the wall with an antiseptic and a primer solution. In addition, each coating to give the opportunity to dry.

-

When using foam plastic, plaster surfaces with beacons that will allow for a smoother plane. Let dry for at least two days.

-

Laying material.

-

Finishing the wall.

Insulation instruction in the following video:

Each insulator requires its own installation technique, but it is important to follow the general rule. After any stage of the work, whatever it was, it is necessary to dry the walls again.

Professional Tips

When carrying out such work, you need to pay attention to the following points:

-

Vapor barrier will help if you make a tight joint at the seams.

-

The heat-insulating layer should not have a high vapor permeability parameter. In the case when the wall is higher than the insulation material, the steam will go outside.

-

To achieve full adhesion of polystyrene foam to the wall, the beacon method of applying the plaster and the method of leveling the glue with a comb are used. This allows air bubbles to pass between the wall and insulation.

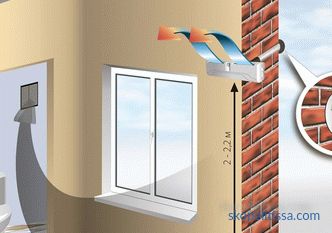

Note! To avoid moisture on the walls, a high-quality ventilation system should be installed in the house - exhaust hoods and valves on the windows.

It can be interesting! In the article on the following link read about floor insulation below.

Conclusion

It is necessary to treat the thermal insulation of your house with full responsibility. Ideally, it should be thought out at the planning and construction stage of the building. And then in the case of full compliance with the technology of all work on the installation of internal insulation on the walls, living in the house will be comfortable and safe.