The need to mount the batten under the basement siding, as well as under any type of finish, is due to a number of factors. The most important of them are the creation of a flat front surface, the provision of air circulation and the possibility of laying a heat-insulating layer.

Laying insulation under the siding sheath

Types and features of the sheathing

The sheathing for siding can be wooden or metal. Both can be used on any type of building and for any kind of siding. The choice depends on the preferences of the developer and on its financial capabilities (metal, as a rule, is more expensive). On the other hand, if you buy dry planed timber, which, moreover, must be treated with an antiseptic, the price difference may be in favor of a galvanized profile.

Wooden crate

Wooden crate for siding is much cheaper compared to metal structures. Installation work is easier and does not require the use of special hardware, usually enough screws or dowels. In addition, wood is more accessible material. On construction sites often remain waste, suitable for use. However, there are a number of features that should be considered when building a wooden frame for siding.

Conventional wooden bars

are used for the wooden frame. It is undesirable to use wood with high humidity (30% or more). Otherwise, the tree will begin to dry under the siding and, if bars of a large section (70x50 or more) were used, the structure may be deformed. Noticeable deformation of wood in the assembled structure is a rare phenomenon and is possible only in case of violation of the assembly technology or the use of improper fasteners.

Not everyone has a moisture meter for a tree, so the humidity of a timber often has to be determined based on our own experience. But in most cases it is enough for installation of street constructions that the material is not freshly sawn. This can be approximately ascertained by resorting to visual inspection. The timber should not be wet to the touch and too heavy.

Sinev on the bars is considered the initial stage of rotting, which is not quite true. Material with similar defects can last as much as ordinary pine or spruce without blue spots. Putrid formations on conifers have brown and reddish coloration, but even such blanks can serve for a long time under certain conditions. However, they should not be used, as well as boards with a bug or putrid lesions.

A similar picture, if it does not speak directly about poor quality, then at least makes you think about the conditions of wood storage

It is undesirable to crate from a bar in places in contact with the ground or close to it, for example, basement structures. Wood tends to absorb moisture and does not tolerate frequent cycles of wetting / drying, that is, it is quickly destroyed in such conditions.

Summarizing the above, we can confidently recommend a wooden crate for all types of structures, except the basement. A properly installed structure will last for decades, if you pay attention to the choice of material and how it should be processed.

Metal crate

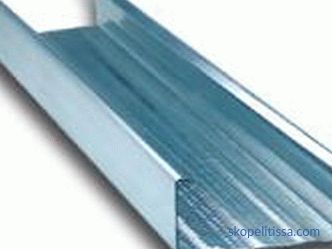

The crate for metal profile siding implies the use of a galvanized profile. You should not use a profile designed for the installation of drywall - it is somewhat different from the material capable of continuously functioning in the street. However, it is often made from the crate under the vinyl siding, probably for reasons of economy.

The main requirement for the metal frame is the presence of a protective coating. In most cases, it is a galvanized coating. A layer of zinc, as you might guess, protects against corrosion.

Galvanized metal profile - used, among other things, to mount the framework for siding

On our site you can find contacts of construction companies that offer the service of finishing and insulation of houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Metal profile for siding is used for any type of building. An exception may be the case of the construction of a fully iron structure in regions with cold climates. The metal has a high thermal conductivity, which contributes to its freezing at low temperatures. If a wooden or brick house is sheathed, there will be no negative consequences, which is not the case with structures made of channel bar or corner.

The most popular profile for mounting has a cross section of 60x25 mm. The use of material with a large cross section is not advisable financially, since the profile mentioned above has sufficient rigidity.Samples with a smaller cross-section are less convenient to assemble and cannot provide structural resistance to external mechanical stresses.

Profile length is 3 or 4 meters. Special connectors are designed for longitudinal fusion.

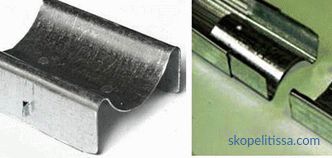

The method of using the connecting elements for metal profiles

The metal thickness on the galvanized siding for siding is 0.3-0.5 mm . The specialist can distinguish the profile for siding from the same for drywall without measuring devices. It is tougher and somewhat harder.

Installation of wooden lathing for siding

Before the start of installation work, you need to calculate the material that is required for the construction of the framework. The number of slats and its cross section depends on the following factors:

-

Type of siding and direction of the panels in the structure;

-

The presence of a heat-insulating layer (implies installation of an additional frame for its installation);

-

Distance between siding and insulation crate (or wall);

-

height of building walls;

-

The number of window and door openings;

-

The presence of the gable, its area and shape;

Installation of a vertical bar of the batten for siding

Consider the simplest situation with facing ten vinyl siding. In most cases, this type of coating is mounted horizontally. Consequently, the rail to which it will be screwed should be perpendicular to the siding strips, that is, vertically.

Mounted lathing for installation of vinyl siding

If insulation is not planned, the timber can be attached directly to the wall with screws, dowels, or , galvanized brackets (for very curved walls).

It might be interesting! In the article on the following link, read about house paneling with house.

ES -scope for battens

The distance between the rail should not exceed 60 cm. The recommended section is 50x25 mm.

Most lumber is made from 6 or 4.5 meter long logs. Moreover, it is very difficult to find six-meter products with a cross section of less than 50x100 mm. Therefore, the most common size of the mounting bar for the batten is 4.5 or 2.25 meters.

In the case of building insulation, you will need a timber, the thickness of which will correspond to the insulation. For example, if it is a 50 mm polystyrene foam, you will have to use a 50x50 mm cross section under it.

The beam is used in the same thickness as the insulation

In the case of mounting the external sheathing for the frame house under the siding, the following sequence is possible Action:

-

A wall of 50x50 mm is mounted horizontally (parallel to the ground) on the wall. The distance between it depends on the heater used. If it is mineral wool 60 cm wide, then the distance between the bar will be 1-2 cm less (for dense packing of wool).

-

The next step is the laying of insulation, for which additional fixing can be used special fasteners.

-

Then, the resulting surface is sealed with waterproofing (hydraulic barrier or vapor barrier);

-

Next, the rail is attached vertically (for example, 25x50), to which mounted siding.

Wooden sheathing is not necessarily the lot of homemade products: often this material is also used by professionals - a video example:

The choice of the direction of the timber (horizontal vertical) to which the siding will be attached depends directly on the dimensions of the sheets of facing material and is determined by the specialist in the place.

Installation of metal batten for siding

The process of constructing a structure made of galvanized profile is not much different from installing a wooden batten. The main differences are in the method of mounting and mounting the frame for laying insulation.

Example of using a metal profile

The direction of the profile relative to the walls also depends on the type of siding and it is better to entrust his choice to a specialist. If insulation is not required, the profile is attached directly to the supporting structure. As an example, consider the sequence of assembling the batten for vinyl siding with a thermal insulation layer:

-

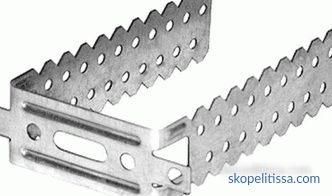

A fastener for a profile is mounted on the prepared wall. Most often it is a galvanized EU-bracket, which is also used to assemble structures for drywall.

-

A thermal insulation material is laid over the fastener. Laying is performed in such a way that part of the fastener is outside the insulation. That is, in fact, the brackets pierce the layer of mineral wool or polystyrene foam.

The heater literally passes through the bracket

-

the waterproofing film is laid in the same way .Fixation is carried out after laying the film with dowels for the foam (fungi).

-

Then a galvanized profile is attached to the protruding brackets (EU-bracket), and a siding is attached to it.

The distance between the profile should not exceed 60 cm. The spacing between fasteners on each profile is 40 - 50 cm.

You can clearly see the metal crate for siding video:

Lathing for basement siding

If this type of sheathing is planned to be used according to its name, that is, for facing the basement or piling space, it would be better if the crate for siding will be located horizontally. This refers to situations where the distance between the top and the bottom of the cap is between 20-50 cm. In the case of covering large areas, such as walls or gables, it is better to use a vertical layout of the batten.

It is more preferable to use a metal profile for ground siding, in any case when it comes to the bottom of the structure. However, the use cases of wood also occur, because of the well-known positive qualities of this material.

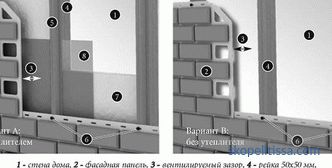

The method and procedure for installing siding depend on the presence of insulation

The ways of arranging the structure depend on the specific situation and are determined by the place, preferably by a specialist which will be directly engaged in installation.

Lathing for decking

In a decking situation, the choice of material for the lathing is more dependent on the purpose of the future structure. For example, if you plan to build a fence, and especially wickets, it is better to pay attention to the metal square pipe. If it is a roof frame, a wooden bar will be more preferable.

The pitch of the lathing under the profiled sheet depends on the requirements for the future construction and the thickness of the metal. A distance of 20–30 cm (for the roof) is considered standard, with the fastener pitch on each profile depending on its cross section and is usually 40–50 cm. The distance of 30–40 cm between the battens will be sufficient even for a relatively thin sheeting ( 0.35 mm).

In the case of using the material as a coating for walls or arranging the fence, thicker grades (0.5 mm) should be used. The distance between the timber or the profile, as well as the pitch for the fastener, in this case will be 50-60 cm.

Most often, profiled sheeting is mounted on the roof. How is the obreshetka done in this case - an example in the video:

This can be interesting! In the article on the following link read about what sheathe the walls in a wooden house inside.

Conclusion

Lathing is a necessary element that must be present regardless of the material used for the building's plating. Installation of siding without lathing is also possible, but in this case one of the tasks is to visually align walls becomes more difficult, and it is difficult to mount siding to walls made of solid materials. Therefore, the frame is needed. A properly designed and well-assembled structure will ensure the preservation of the walls of the structure throughout its life.