Metal tile, as a new type of roofing, appeared on the market as a cheap alternative to ceramic tile. Users immediately appreciated all the advantages of the new material, and it became very popular. Manufacturers in the meantime did not stop there. So there was a whole model line. This article will talk about one of them, and more specifically, about the metal tile "Cascade". About how she came into the world, what are its design and design features, be sure to indicate the advantages and disadvantages of the material and describe the method of installation.

A bit of history

The metal tile received the name "Cascade" in Russia, where it is produced today by the company "Factory Profile". But the technology was developed by a Finnish company, and the first products that were called Rannila Cascade appeared there. Products quickly became popular. The Finns began to deliver it throughout Europe, and from them it came to Russia.

To transport finished products from abroad is to pay additional customs duties. Therefore, we bought the technology and began to produce metal roofing in our country. They just gave it a shortened name - Cascade.

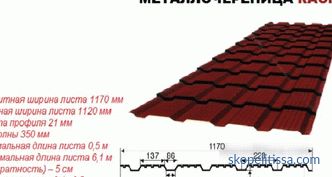

What is a metal shingles "Cascade"

This is a standard profiled sheet with a thickness of either 0.4 mm or 0.5. In Finland, only galvanized sheets with a thickness of 0.5 mm are used, because this is ideal for roofing materials, taking into account the low cost of the finished product.

At the same time, the sheet material is covered with a polymer composition, which increases the characteristics of the tile, thereby increasing the operational period of the roof covering. Usually polyester is used as the polymer. We add that the polymer layer makes it possible to arrange the metal tile in different colors, where, in principle, there are no restrictions.

As for the exterior design, the roof of the Cascade differs from the classical models with more strict lines of the applied profile . If you can compare a profile with something, then only with a chocolate bar. The design turned out to be strict, but at the same time refined. At the same time, all designers noted that such a design of metal tiles fits modern styles.

Builders, however, note that a profile of this type makes it possible to contain large longitudinal loads. And this suggests that the roofing structure covered with the Cascade calmly withstands quite serious loads from the snow cover without deforming the roofing material. And this position is relevant in regions where snow falls in large quantities. Although buy a sheet on the roof of the Cascade is possible for any design, erected in any region. The material is universal.

On our website you can find contacts of construction companies that offer design services and repair of the roof . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Advantages and disadvantages of the roof Cascade

Let's start with the advantages of the roofing material:

-

The lifetime of the roof covering is 50 years. And this, as manufacturers say, is not the limit. The main thing is to correctly carry out the installation process taking into account the recommendations.

-

High resistance to mechanical loads . The metal tile on the roof does not bend, does not move, does not break, does not crack.

-

High anti-corrosion properties . We must pay tribute to manufacturers who use galvanized polymer coated sheets in production. Both layers perfectly cope with precipitation, hence the long service life of the material.

-

The metal tile of the "Cascade" brand does not lose its color under the influence of the sun's rays throughout its service life on roof structures.

-

Polyester does not change its properties under the influence of changing temperature and humidity . He never cracks.

-

The low specific weight of the roofing material makes it possible to save on the roof system and the batten, using small section lumber to assemble them. This is classified as "savings".

-

Easy to install .

-

Reasonable price .

The last indicator is an important factor of choice. Therefore, a few examples of metal "Cascade" with prices.

It might be interesting! In the article on the following link read about an online calculator for calculating the roof of the roof, a program for calculating the quantity and cost of materials on the roof .

Price of metal tiles Cascade

In general, the model range differs in price depending on the thickness of the raw sheet used and the manufacturer. For example:

-

Plant " Severstal " produces metal tiles under the name Cascade 1115 mm wide, 1080 mm long, 25 mm wave height and 0.5 mm thick sheet. The wave step is 300 mm. This is the distance across the crate (more on that later). And it costs one square meter of coverage - 500 rubles. In this case, the plant gives a warranty of 25 years.

-

Plant NLMK with the same parameters of metal tiles offers material at a price of 470 rubles. / m²

-

The same factory offers material made of metal with a thickness of 0.4 mm . Its price with the same dimensional parameters is 1060 rubles for one sheet, taking into account that its length is 2200 mm. It turns out about 418 rubles. / m²

-

The same manufacturer, all the same parameters, only the length of the profiled sheet is 1 m . Its price is 480 rubles or 418 rubles. / m²

It should be noted that many manufacturers produce Cascade today The benefit of the technology is based on the use of a special form that forms the very profile of the material. But there is no strict GOST for this product. Therefore, all manufacturing plants in the production process are based on the technical conditions, which they themselves develop. When developing conditions and the equipment of production are considered. Therefore, sheet sizes may vary from different manufacturers.

For example, the ChMK plant produces material with a width of 11160 mm, a wave height of 40 mm, and a wave step of 350 mm. The length of the product varies in the range of 0.5-8.0 m with undercutting every half meter.

In the video they talk about the metal tile of the "Cascade" model from the ChMK plant:

It can be interesting! In the article on the following link, read about how to choose a country house for permanent residence: set the priorities correctly .

Technology of mounting metal shingles from Cascade

In principle, the technology of assembling the roof of "Cascade" is no different from the standard installation process. Just when installing the crates will have to take into account the wave step.

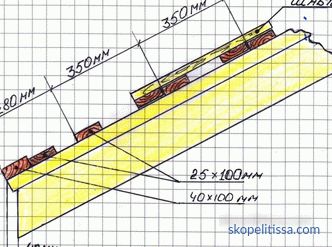

So, the process of building a roof begins with the installation of a truss system. Here there is one requirement - the installation step of the rafters is 60 cm. The second stage is the installation of the batten. Here the installation step depends on the wave pitch. For products from the ChMK plant, this parameter is equal to 350 mm, for the manufacturer NLMK and Severstal - 300 mm.

As for the sheathing under the metal roofing on the Cascade roof, it is better for it to use boards with a thickness of 25-35 mm and a width of 100 mm. You can do cheaper option - wooden bars section, the width of which varies from 25 to 40 mm. The main task of the manufacturer of work is to strictly adhere to the wave step when mounting the elements of the batten.

And some useful recommendations that should be taken into account during the installation of the Cascade.

-

The laying of the roofing should be carried out from left to right.

-

The panels stack overlapped .

-

The capillary groove of the metal tile of this brand is located on the left side. Therefore, the installation is carried out so that the left edge of the top row panel falls under the right edge of the bottom row sheet.

-

The first row of profiled sheets laid in the eaves zone is lowered 4-5 cm downwards. That is, the material should protrude beyond the overhang.

-

Fastening is carried out, as usual, with roofing screws. It is necessary to screw in fixture through a wave on a site of an overlap of sheets of the following upper row. That is, so that the fastener heads are hidden by the panels of the upper rows.

The video shows how to lay the metal tiles of the "Cascade" brand on the roof of the house:

It can be interesting! In the article on the following link read about the original tree house .

Conclusion on the topic

It is difficult to say something further about this roofing material. In fact, it differs from other models only in its appearance, or rather, in its profile. This is its distinctive feature. But there is also a purely constructive moment - this is the location of the capillary grooves. This fact must be considered during the installation process.

Rate this article, we tried for you