Aerated concrete, is one of the varieties of cellular concrete and is available in blocks. This is a modern building material designed for the construction of low-rise buildings. Blocks made of aerated concrete have become very popular lately with private developers. Of them build exterior and load-bearing walls, as well as internal partitions, foundations and basements. Consider what features have aerated concrete blocks, their characteristics, and what size of aerated concrete block is used for the walls of the house.

Additional buildings are often made of aerated concrete - garages, bathhouses, gazebos, fences, etc. This versatile material attracts with excellent technical characteristics and low price.

Production technology of aerated concrete blocks

Natural materials are used to manufacture the material, mixed in defined proportions :

-

quartz sand (~ 60%);

-

cement (~ 20%);

-

lime (~ 20%);

-

aluminum paste (~ 1%);

-

water.

Sand is pre-ground with special equipment. The ground sand is mixed with cement and lime. In the resulting composition, add water and aluminum. The porosity of the raw mass is formed by the reaction of lime and aluminum paste, as a result of which hydrogen is formed. Pores in aerated concrete are quite small (from 0.5 to 2 mm in diameter), and evenly distributed.

The finished raw meal is poured into pallets. After that, it is left in a sealed room with high humidity until it solidifies. During this time, the mass first increases in volume due to the formation of pores, and then turns into solid plates. At the next production stage, the plates are cut into blocks. The result is a block of aerated concrete, the dimensions of which correspond to a particular type of material.

Next, the front side of the blocks is polished, after which they are placed in an autoclave oven where they, being under a high pressure, are exposed to heat treatment.

In the autoclave roasting process, aerated concrete becomes as strong as possible, and its subsequent shrinkage is minimized - less than 1 mm / m.

Technical characteristics of gas blocks

Aerated concrete has been used in low-rise construction in different countries for more than 80 years. During this time, he has established himself as a reliable and convenient material with excellent technical characteristics. Its porosity reaches the level of 85% of the total volume. At the same time it is quite durable. Experts say that gas blocks have the porosity of wood and the strength of stone.

The gas-block has the following characteristics:

-

low weight ;

-

low thermal conductivity ;

-

increased sound insulation ;

-

environmental friendliness ;

-

overall dimensions blocks;

-

fire resistance ;

-

ease of processing during construction.

On our site you can familiarize yourself with the most popular projects of aerated concrete houses from building companies represented at the exhibition houses "Low-rise Country".

The strength and thermal conductivity characteristics are interconnected and depend on the brand of gas blocks. The higher the porosity of the material, the better it retains heat, but at the same time its strength decreases. The lower the porosity, the stronger the blocks. This is a very important factor that is taken into account when choosing sizes of building materials.

There are aerated concrete blocks, the characteristics of which are ideal for the construction of load-bearing exterior walls, but during construction in cold regions they require additional insulation. Sometimes the projects of houses provide for the use of "warm" types of gas blocks, the walls of which are reinforced with reinforced concrete structures.

Dimensions and marking of aerated concrete blocks

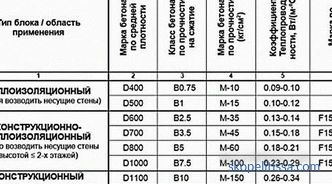

Basic The classification of this building material is carried out by brand.

-

Stamps in the range D1000-D1200 are material for structural purposes.

-

Stamps from D500 to D900 are heat insulating and at the same time structural material.

-

D300-D500 , these are exclusively thermal insulation blocks.

On our site you can find contacts of construction companies that offer construction services aerated concrete houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

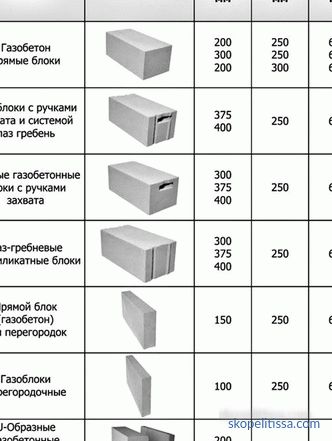

Separate gas-blocks and in form. Most often used products that look like a large brick. Sometimes with side grip handles. But if necessary, you can use blocks with a groove-ridge side-docking system. This option is convenient because it allows you to build walls with a minimum number of seams and save on masonry mix.

There are still blocks that have a U-shape. They are used for laying complex architectural elements :

-

columns;

-

arches;

-

bay windows;

-

openings;

-

jumpers.

Blocks are available in standard sizes. The dimensions of aerated concrete blocks are selected separately for the construction of walls, partitions, lintels.

Pros and cons

Aerated concrete has much more advantages than disadvantages. So, its low weight allows building houses on light foundations and in areas with weak ground. High thermal insulation makes it possible to build warm comfortable buildings without a complex thermal insulation system. With a small weight, the blocks are quite large in size.

One gas block in the masonry replaces several bricks. This ensures the rapid construction of aerated concrete houses with minimal labor costs.

Separately, it is worth noting that, like a stone, a gas-block is not amenable to burning, does not undergo processes of corrosion and rotting, does not collapse under the influence of harmful insects. In addition, the porosity of the material is a guarantee of self-ventilation of the premises in the house (as in wooden buildings). Provided that the exterior and interior decoration will also be "breathable."

The ideal geometry of the blocks allows laying with a special glue and producing a very thin seam. And this, in turn, reduces the number of "cold bridges" through which heat leaves the premises during the heating season.

It can be interesting! B article on the following link, read about laying walls of aerated concrete blocks.

An important advantage is the ease of processing of gas blocks. Thanks to this property, it is possible to build buildings with complex configurations and individual structures, adjusting the blocks to the desired shape. Another plus that distinguishes the gas block - the block sizes are different, they allow you to choose the right one for a certain type of building.

Minuses aerated concrete:

-

The foundation for a house should be as stable as possible, since during vibrations aerated concrete walls may crack. However, this disadvantage is eliminated by the proper selection of material by brand and size.

-

When heavy structures (plumbing, furniture, etc.) are hung on the walls, you need to use special dowels and other retaining hardware.

-

Compressive strength is not high enough, therefore, when building large mansions, it is necessary to provide additional strengthening of walls.

Prices

Aerated concrete blocks are produced by various domestic and foreign enterprises. At the same time, non-certified material from unknown firms is present on the market at low rates. From this option it is better to immediately abandon.

Pricing of aerated concrete products is formed taking into account brand and size. For example, blocks of size 20/30/60 with a density of 500 kg / m³ cost about 130 rubles. a piece. Accordingly, the larger the size of aerated concrete blocks, and the higher their characteristics, the more expensive they are.

How high-quality aerated concrete is used, see the video — usage, nuances and stages of aerated concrete construction:

Aerated or foam concrete

Foam concrete is another representative of cellular concrete. In terms of its parameters, it is very similar to aerated concrete. But there are significant differences. So, foam concrete does not require special equipment. It hardens in the process of natural drying, and it can be made right on the construction site. If not very skilled craftsmen are engaged in this, then the quality of the house may suffer. Aerated concrete is produced in the factory and is accompanied by official documentation that protects homeowners from marriage.

With the same density, blocks of aerated concrete are stronger as they are processed in a furnace. Simple conditions for the production of foam concrete lead to the fact that foam blocks can have a non-ideal form. When processing foam concrete can strongly crumble. The only advantage of foam concrete over aerated concrete is a more affordable price.

Calculation and selection of aerated concrete blocks

Proper construction is very important for the construction of any object all materials. Otherwise there may be additional costs.In the full project documentation must contain accurate calculations of building materials. The calculations take into account the size of the block of aerated concrete for the walls of the house, the total area of the walls, the area of all door and window openings, as well as the trimming.

Gas blocks must be selected separately for different wall structures . For partitions take blocks with a small thickness. External walls are made of a material with high strength, etc. It is important to consider the size of the products, the presence of a groove-ridge system, and other characteristics.

When designing, the architect immediately enters into the calculations the parameters of one or another type of gas blocks. If an individual project is created for construction, the type of aerated concrete is discussed with the client, and only after that the engineering work of the designer begins.

When purchasing material of a selected type, you should check the accompanying documentation.

In addition, it is advisable to personally verify that the material does not have cracks, a defect in shape, and differences in color. If there are such flaws, it means that they are trying to sell gas-blocks of not very high quality, or when storing it, the necessary conditions were not fulfilled.

What a house of aerated concrete looks like before finishing works is shown in the video:

This can be interesting! In the article on the following link read about the difference between aerated concrete and foam concrete.

Conclusion

Aerated concrete blocks are a versatile modern building material with good technical characteristics and low price. He is highly regarded by experts and professional builders. Dimensions and other characteristics of aerated concrete make it possible to build high-quality, comfortable and beautiful cottages in record time for concrete materials.