A polycarbonate greenhouse comes to replace the film and glass greenhouses. From the article you can learn the advantages and disadvantages of this material, as well as the most common designs of such greenhouses. Where it is better to locate a greenhouse, if you need a foundation for small structures. What are the features of the installation of polycarbonate greenhouses, and how to take care of them afterwards in order to extend the service life.

What is the difference between a greenhouse and a greenhouse

Many are completely identify these concepts, but the greenhouse and greenhouse are still different designs. The main differences are as follows:

-

Greenhouse - in order to maintain the required temperature, this construction requires sunlight or the use of additional energy sources. Such a structure is large in size and an adult can move freely within.

-

Greenhouse - represents an energetically self-sufficient system. The influx of heat occurs due to reactions occurring in organic compounds and the greenhouse effect under the influence of the sun. Doors in greenhouses do not, to ensure access to the landings provided for the removal of the upper structural elements.

Greenhouse will be convenient for seedlings or undersized crops. Adult tall plants are placed in greenhouses.

Pros and cons of polycarbonate greenhouses

Despite the fact that the cost of polycarbonate is still higher than the usual polyethylene film, many summer residents make a choice in its favor. Polyethylene is enough for a maximum of two seasons, and glass greenhouses are also often cracked and fought from mechanical stress or temperature changes.

Polycarbonate has a number of advantages :

-

Durability - it is able to withstand quite large loads, it is well preserved in case of mechanical damage. The strength of polycarbonate is 200 times higher than that of glass.

-

Light transmittance - transmits about 85% of the scattered light from the sun, while it provides plants with protection from harmful UV rays.

-

Thermal conductivity - has good thermal insulation properties, which allows you to ensure the fit of the desired air temperature. Polycarbonate perfectly passes heat inside and holds it there.

-

Resistance to abrupt temperature changes - able to withstand temperatures from -40 ° C to + 60 ° C.

On our site you can find contacts of construction companies that offer the service of design and installation of greenhouses, greenhouses and similar structures and small forms for a country house. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Stiffness - the material is easy to bend, while it is equipped with internal ribs that give strength to the structure.

-

Low weight - polycarbonate sheets are easy, so you do not have to build a deep foundation for a greenhouse and make a heavy frame.

-

Easy to assemble - polycarbonate sheets are well cut even with a simple knife, and they can be quickly drilled with a drill.

-

Easy to maintain - polycarbonate has a dust-repellent surface, dirt is removed with ordinary water.

-

Fire resistance - this greenhouse will not flare up, but will simply start to melt in case of fire.

For all its merits, polycarbonate has some drawbacks:

-

There is a risk to break the protective layer and the sheet will lose its original specifications.

-

When exposed to high temperatures the material expands , which must be taken into account during installation - leave a gap between the elements.

-

Over time, polycarbonate turns yellow in the sun .

It often happens that dust penetrates into the cells of the polycarbonate sheet , debris and water, leading to mold and mildew. The material becomes opaque and loses its properties. In order to avoid this, during installation it is necessary to work out well all the joints and fasteners with a sealant and aluminum tape.

On our website you can familiarize yourself with the most popular projects of arbors and other small forms for private houses - from construction companies represented at the exhibition "Low-Rise Country".

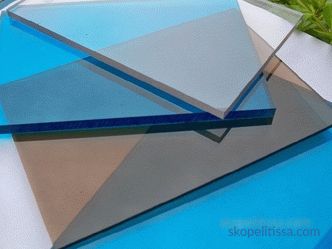

Types of polycarbonate

Polycarbonate can be of two types:

-

Monolithic - looks like a flexible sheet of glass, has different colors and sizes.Its service life reaches several decades. Mainly used for fencing, canopies, canopies.

-

Cell is two sheets with stiffeners between them. Cavity inside of which air, just give the material insulating properties. This type of polycarbonate is used in the construction of greenhouses and greenhouses. He has a shorter service life, but also a lower price compared to the monolithic.

Designs of polycarbonate greenhouses

Greenhouses may differ in their design, depending on which plants will be grown there. The most common options are:

In-depth

It is not often found on the plots. This is a deep, long pit with a built-in harness and a covered frame around the perimeter. The advantage of this design is a small surface that provides good energy saving. The rarity of use is due to the complexity of manufacturing and the inability to move such a structure.

Butterfly greenhouse

Its device provides unhindered access to plantings from each side . This construction is also more efficiently ventilated. Such a polycarbonate greenhouse has dimensions of about 4 m in length, but may be small, depending on the needs.

Greenhouse-bread box

It is an arched structure, which consists of a pair of independent planes. The walls are hinged and can be easily moved away to access the plants. There are models with one movable flap or immediately with two. As a rule, such polycarbonate greenhouses are presented in mini-versions.

Belgian greenhouse

This is a structure that has a flat lean-to roof. Usually it is small in size, used for miniature landings.

For high and large plants, greenhouses are chosen that can be made for almost any size. On sale there are also ready-made options with a different shape of the roof.

The foundation and frame for a greenhouse

Some gardeners put greenhouses without a foundation but it is recommended to do it. It will protect the structure from being blown away by gusts of wind and will allow it to be moved to the right place without difficulty. Time building the foundation takes quite a bit.

It is constructed in the following way:

-

The necessary materials and tools are prepared: wooden beam 12x12cm, special screws for wood, tape measure, roofing felt, hacksaw , antiseptic, shovel.

-

A hole is dug around the perimeter, making it 5 cm wider and deeper than the size of the beam.

-

I put t roofing material into the duged trench .

-

Then the bar is cut into pieces of the required size and treated with antiseptic.

-

Boards are put in a hole , and the roofing material is wrapped on the side of the foundation, if necessary, then it is fixed with a construction stapler.

-

Bars are fastened with self-tapping screws.

It might be interesting! In the article on the following link read about the greenhouse with a zipper.

After the foundation is ready, you need to install the frame. This is a skeleton that bears the entire structure, so its strength is important. The most famous and affordable option - a wooden frame. To build it is simple, but it is less durable. A tree without additional processing will last about 4 years, and with the use of an antiseptic it will last up to 10 years.

A metal profile is also used for the frame, it is more expensive, but the service life is longer than that of wood. However, it is more difficult to mount such a structure, besides, the metal is still subject to corrosion.

It will be easiest to purchase ready-made greenhouse frames for polycarbonate. But here you should follow some recommendations:

-

arcs should consist of of the minimum number of elements - ideally to be solid-curved;

-

it is better to choose a metal profile with a rectangular section 2x4 cm, a smaller figure may not be suitable, especially when mounting the base of the greenhouse;

-

metal thickness , from which made the frame must be at least 1.2 mm - is the key to a long service life of the structure.

Modern greenhouses provide lighting, ventilation and irrigation systems. This can significantly reduce the time to take care of plants, but all the nuances should be taken into account when planning a purchase.

Choosing a place for a greenhouse

In order to provide the plants with the necessary conditions for growth and development, and eventually get a high yield, you must start by choosing a place for a greenhouse. This factor also affects the size of the greenhouse.

It is recommended to consider the following:

-

it is better to choose the sunniest part of the site - the greenhouse should be lit most of the day;

-

it’s impossible to place the planting in the lowland , water accumulates there, and the plants will hurt and rot;

-

the greenhouse is set, Focusing along the length of the structure from north to south;

-

if the groundwater is located close to the surface at the site, then a deep greenhouse is made on a high mound , or refuse it at all, giving preference to other types of structures.

Features of mounting a polycarbonate greenhouse

When building a polycarbonate greenhouse, you should consider a number of features of working with this material.

It might be interesting! In the article on the following link, read about what to look for when choosing a land plot.

It is recommended to follow these rules:

-

to minimize the number of slots at the junction of the elements, a hinged roof, for example, should close close to the overall structure;

-

in the manufacture of the arch polycarbonate sheets are bent only across the direction of the cells ;

-

the frame must have stability to humidity, mold and fungi;

-

the inner part of the polycarbonate sheets must be protected from water , that is, the sections are carefully insulated - a special profile is used or the elements are put over the sides eats and the cuts are then glued;

-

you cannot save on the frame - the wood should be of high quality, and the profile should not be too light, especially for large greenhouses.

-

the installation of a greenhouse is early spring or deep autumn , because the optimum temperature for working with polycarbonate is about + 10 ° C - with a significant change in temperature, the sheet changes its dimensions, and subsequently may appear cracks.

How a greenhouse is built, see the following video:

How to wash a polycarbonate greenhouse

During the season, the greenhouse has enough time to get dirty with soil, traces of plants, dust. Its light transmission ability decreases, which affects the development of landings. Sometimes polycarbonate may accumulate microorganisms that can destroy seedlings or ripening crops. In order to avoid these troubles, the greenhouse should be washed in a timely manner.

Never use abrasive cleaners or hard brushes, otherwise you can damage the protective layer on the polycarbonate. It is recommended to take a soft cloth or sponge and water with soda. Soap solution is also suitable. After processing the greenhouse all detergents must be carefully removed. It is best to drench the entire structure with water from a hose.

Clearly washing polycarbonate is in the following video:

It might be interesting! In the article the following link read about the Paris Pavilion from Tom Raffield for the Chelsea Flower Show.

Conclusion

If before the choice of material for greenhouses and greenhouses was very small - plastic film or glass, now the situation has changed. Appeared polycarbonate, which is widespread among gardeners. Various modifications of greenhouses from this modern material allow everyone to find a suitable option. And with proper care, such an acquisition will pay off.