The old gas cylinder is an ideal example of how many different useful products can be made from it that are used in the country house. In this article we will talk about a very necessary device - a brazier from a gas cylinder. We will tell you how to cut it, what precautions you need to follow, how to install all the required elements. And we will show on the photo and video various design options for such a brazier.

Disassembling a cylinder

Cut the gas cylinder to the required dimensions and shapes immediately, not checking its contents is impossible. First of all, it is necessary to empty the cylinder, suddenly there is gas in it. Therefore, the valve should simply be opened, releasing the remnants of the contents.

Then you need to unscrew the valve. Make it a gas key. It is usually easily unscrewed, but sometimes it becomes a problem for those who first encounter a similar situation. Just in some models of cylinders, the valve is blocked by two studs. They must be removed with pliers. After that, the valve is easily unscrewed.

The next step is flushing. The balloon is half-filled with water, shaken or pumped, then water is drained. By itself, the gas has a specific smell, which gives it a special additive - odorant. To get rid of this smell, detergent or bleach is added to the wash water.

Cutting the cover

The dimensions of the barbecue from the gas cylinder are determined by the size of the latter. But as for the parameters of the cut out cover, there may be different options. It can be short or full length of the cylindrical part. With regard to the latter option, it is necessary to understand that the gas cylinder is a suture pipe, with spherical caps welded on both sides. In one, a through hole is made under the faucet, the second is a deaf bottom of the product. So the lid of the barbecue, and accordingly the cut part, can be made from one welding seam to the opposite.

So the gas bottle is ready. Apply the markup for cutting. In principle, these are two longitudinal lines dividing the balloon in the longitudinal direction in half. Apply the markup is very simple.

-

The circumference of the cylinder, that is, its "perimeter" is 96 cm.

-

This indicator is divided by "4" , it turns out 24 cm.

-

The longitudinal seam of the cylindrical part is taken as the measuring point, that is, it is laid on two sides by 24 see

-

The mark is followed by longitudinal lines , the ends of which should not reach 2-3 cm to the cross seams.

-

The ends of the longitudinal lines are connected along the perimeter of the cylindrical part. The markup is applied with chalk.

The hemispherical rectangle marked with a chalk in a hemispherical form is not a lid. The size of the latter in width by 10 cm will be smaller. This parameter is deposited from one of the plotted longitudinal lines. After that a cover is formed with chalk, which will have to be cut off.

Cutting is carried out by a grinder and a diamond-coated cutting disc. Many masters recommend filling the bottle with water before cutting. In this way, the question of the stability of a cylindrical product and cooling the cutting tool is solved.

You must start cutting along one longitudinal line. It cuts from end to end of markup. Then it is necessary to weld the hinges to the cut-off area. They can be used any: door, furniture. The required number of loops with smaller sizes is four; large ones will need only two. They are simply applied to the cylinder so that the cut is in the middle of the two parts of the loops. The latter is welded to the cylinder electric welding. This stage is done specifically now, because it is easier to fit the cover to the balloon and hinges, while it is not completely cut off.

On our site you can familiarize yourself with the most construction sites in the Moscow Region country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

It remains only to cut through the remaining three lines: one longitudinal, two transverse. Immediately to the lid on the opposite side of the hinges, it is necessary to weld the handle so that it is convenient to open the barbecue from the gas cylinder.

And one more thing that will make the manufactured structure more convenient to use. In the place of the welded hinges on the cylinder, two stoppers must be welded to hold the cover open. That is, that it did not fall for the device. For this you can use the corner 40x40 mm. 2-3 cm long pieces are cut out of it. They will be limiters.

In order to close the lid between it and the cylindrical part there are no gaps, it is necessary to create shelves along the entire perimeter of the cut part. This will require a steel strip with a width of 2-3 cm and a thickness of 2-3 mm. The strips are simply welded from the inside of the canister with a discharge to the outside of half of its width. In addition, these welded strips will hold the lid so that it does not fall inside the brazier.

Other design changes

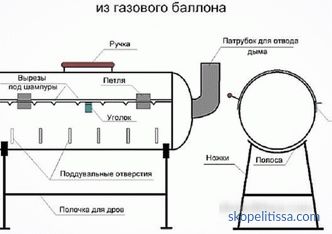

In principle, the brazier is from a gas cylinder almost ready. It remains only to weld the legs and make holes in the cylinder itself to install the skewers and supply air to the burning zone of the coal. Start with holes for skewers.

One of the plotted longitudinal lines remained unused. On it it is necessary to put additional marks dividing lines evenly into several segments. The length of the last 8 cm. At their ends and make through holes with a diameter of 10 mm, using a drill and drill.

From the opposite side of the opening made on the welded steel strip, it is necessary to make grooves for the skewers. They must be located exactly opposite the holes made. The grooves make grinder and cutting disc.

Now we need to make holes for supplying air to the inside of the bbq. To do this, from the welded seam of the cylindrical part of the cylinder in two directions, it is necessary to postpone 10 and 20 cm. Longitudinal lines are drawn along them, in general there will be four of them, two on each side of the seam. They also share labels with a distance of 5 cm. After that, the labels on two paired lines are interconnected. On them, the grinder and the cutting disc make through slots.

It remains to plug the hole into which the faucet was screwed. Here they simply take a plate with a thickness of 2-3 mm, which is welded to the hole, scalding with a continuous seam on all sides.

The video shows the sequence of operations for the production of brazier from a gas cylinder:

As for the legs, there are a lot of options. The easiest - legs from a steel corner. The main thing is to accurately select the height of the gas grill. It is optimally considered from 60 to 80 cm, that is, convenient for the growth of an adult. Although there are low modifications.

You can show imagination and make the legs of the original shape, decorated with patterns. You can attach legs to them, make the device mobile, mobile, as shown in the photo below.

On our site you can find contacts of construction companies which offer construction services of small architectural forms . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

How to make a barbecuer

In principle, a barbecue was made of a gas cylinder in the same way as a brazier, with only a few additions. First, the grille is installed inside. It is removable, but for it it is necessary to install supporting shelves inside the cylinder. They are made of steel angle 25x25 or 32x32 mm. The length of each shelf is 10 cm, they are welded on two opposite sides of the opening, three pieces at the same distance from each other. Location in height - under the holes for the skewer. Respectively and from the opposite side at this height.

Secondly, it is necessary to install a chimney. There are a lot of options:

-

on the cover ;

-

on the side , with an insert into the hole for a crane;

-

near the cover in the cylindrical part.

How to improve the brazier

Yes There are many additional trifles that will make the process of cooking meat, poultry or fish on the barbecue grill a convenient and easy process. Here are a few such trifles:

-

A nut is welded to the lid of the device or to its cylindrical part, and a thermometer is inserted into the nut. Now you can monitor the temperature at which the meat dish is cooked.

-

tank can be installed on the chimney. In it the lattices are installed on each other. This add-on is a great smokehouse design.

-

It is possible to install a lattice inside the brazier to its full length. This will be the grate. His task is to keep the coals, but to pass through the ashes so that it does not interfere with burning wood.

As for the decoration, there is also a huge field of activity. That just do not come up with the master. For example, here is an option in the form of a steam locomotive, as in the photo below. Definitely, this design will decorate the territory of the villa.

From the video you can learn how to create a brazier from a gas cylinder:

It can be interesting! In the article on the following link read about the top 10 stairs in the modern style: difficult in the simple .

Conclusion on the topic

Today, finding barbecues from a gas cylinder with drawings and exact dimensions on the Internet is not a problem. Various options of simple designs and with additional convenient options are offered. But the main thing, as practice has shown, is the exact observance of the height of the skewers above the coals. The distance is small - the meat will burn, the distance will increase - the dish will be cooked for a long time.