Regardless of the size of the plot, a sandwich panels will be a useful addition to the villa territory. The material proposed in the article will acquaint you with the possibilities of using buildings and the merits of wall material. You will learn how the installation and installation of the foundation for the hozblock takes place, what constitutes a complete set of typical buildings, and what are the advantages of a turnkey order.

Features of the hob from sandwich panels

Hozblok (cabins) on country sites became common detail, a modern replacement for the usual wooden sheds. Functions of convenient and compact constructions expanded; they found many new uses. By purpose of construction can be divided into the following types:

-

Auxiliary . The place of storage of garden tools, things, firewood for the stove or barbecue.

-

Construction . Are established for the period of construction; used for storing tools, building materials or for temporary residence of the construction team.

-

Country . Seasonal housing for periodically visiting owners.

-

Economic . Cabin is often determined under the toilet, shower, summer kitchen. Popular cabins, adapted to the garage, bath (with additional inner lining) or a guest house.

A variety of uses made possible by advantages, including the following advantages:

-

Profitability erection and subsequent maintenance.

-

Long service life (20 years) with the possibility of multiple assembly / disassembly (for some models).

-

Operation without changing the characteristics and appearance (no overhaul is needed). Sandwich panels - fire-resistant material, not exposed to dampness and temperature changes.

-

High degree of noise and heat insulation .

Properties of sandwich panels

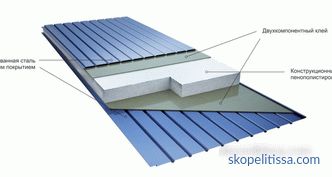

Sandwich panels are understood as several building materials with a similar three-layer structure. Such panels consist of two external rigid sheets, glued to the inner layer of insulation by hot or cold pressing. The shell of the panels is made of metal, PVC, wood sheet material (for example, fiberboard) or magnesite plate.

The insulation is solid polystyrene foam or polyurethane foam, which is pumped under pressure. SIP panels, a kind of sandwich panels, in which OSB plates serve as the outer layer are often used as wall material. The finished panels (and the construction of them) have important advantages:

-

Low weight panels . For construction does not require a strong foundation. To install a kitchen or a barn of sandwich panels, any prepared site, from bedding from crushed stone to concrete slabs or asphalt, will do.

-

Speed works . Installation takes several working days and can be carried out at any temperature; additional finishing is optional.

-

Structural strength . The necessary and sufficient rigidity provides the metal frame of the building.

-

Easy maintenance . If the need arises, the panel changes without disassembling the structure.

On our site you can find contacts of construction companies that offer the service construction of small architectural forms. You can directly communicate with representatives by visiting the low-rise country exhibition.

Construction technology

The basis of a hopper is a metal or wooden frame on which a sandwich panel is fixed. Castle connection provides tightness of the building with good parameters of moisture and heat insulation. The sequence of installation of the hozblok for giving from the vulture panels is as follows:

-

The platform is being prepared. In most cases, the foundation is not required. If necessary, install pillars or screw piles (in case of problematic soil).

-

Frame assembly . After the foundation has been equipped, a lower binding is mounted on it, on which the framework is assembled (or welded). The material for the bearing part is selected taking into account the operating conditions of the dog house.

-

Installation of panels . Before installation, check the installation of the frame. If the verticality and horizontal position are disturbed, the finished object will have problems with tightness and rigidity of the connection.

-

Installation of the roof and flooring . The angle of inclination of the roof is set to at least 5 ° so that water does not linger on the roof.Roofing material can be plywood, roofing felt or galvanized iron (typical models).

About the installation of garages from the sandwich panels in the following video:

-

Installation of windows and doors .

-

Finishing work . Finishing is done with siding, wall paneling or paint. Inside the walls are often sheathed clapboard.

On our website you can find contacts of construction companies that offer a bath construction service. You can directly communicate with representatives by visiting the low-rise country exhibition.

Choice of foundation

If there is a slope on the site, it is recommended to equip the pile-screw foundation for the foundation of the fixed utility block. Installation of such a base is carried out in a mechanized way and takes one day. This technological option has additional benefits:

-

Installation is carried out year-round ; technology is used on all types of soil.

-

The process is not accompanied by excavation , it does not include pouring with concrete and soil removal.

A special feature of the technology is the need for flooring and decorative facing of the basement (on an uneven landscape). Unlike the pile-and-screw, slab foundation is a solution with a finished floor. Filling the slab at the base of the hopper is carried out on any soil and also has its own characteristics:

-

Installation takes one to two days , but the setting of concrete occurs within three weeks.

-

Method includes excavation . Arrangement of formwork and removal of excess land will be required.

-

The method depends on the weather and is not suitable for a section with a slope.

It might be interesting! In the article on the following link, read about building a utility block with a drovnik.

Completion of trailers

The following materials are included in the kit of a collapsible trailer or hoe-block according to Canadian technology (alternative name for sandwich panels):

-

Folding frame . The main element, made of shaped pipe (assembly is carried out on bolts); the cross section of the details is determined by preliminary strength calculations.

-

Set of wall and roof panels . The thickness of the modules is chosen taking into account the climatic conditions of the region. The thickness of the modules for residential sheds in the central region of Russia starts from 100 mm, 50-60 mm is enough for a garage.

-

Metal door , with mineral wool insulation or without (depends on the purpose of the object). Insulated door does not freeze around the perimeter and is not deformed in the cold.

-

Window . To achieve maximum energy efficiency, at the request of the customer are installed double-glazed windows.

About the shed assembly in the following video:

-

Optional Equipment . Beam for the lower trim, finishing materials (plywood, linoleum on the floor), electrics (light, sockets, wiring). The package can include a vestibule - an internal partition with a door.

-

Customer’s desire . Production of the hozblok with the additional equipment is possible: a peak, a heater, rolling shutters.

Turnkey power block

Many construction companies offer the service of building a power block from turnkey sandwich panels, including design, delivery and assembly. This service is a convenient option that allows you to quickly get a building that is fully operational. The hozblok for giving on a turn-key basis from panels has the following advantages:

-

Design . You can order a draft of a shed any configuration, with rooms that will be different in purpose. A popular option is a summer kitchen model with a pantry or hozblok with shower and toilet.

It might be interesting! In the article on The following link read about the varieties of country toilets with a shower.

-

Calculations . The project will take into account not only any of your wishes, but also the norms of SNiP; wind and snow loads will also be calculated.

-

Erection . Assembly work does not require the presence of the customer; you can safely go about your business.

-

Quick Installation . Depending on the project, the building is delivered to the site as a finished product or mounted on site. Building a standard project takes three to five days (without foundation).

-

Additional services . After installation, the object is connected to communications; if necessary, related work is carried out (furnishing with furniture and equipment).

-

Ready for use .Works are carried out neatly, the hozblok has insulation, interior decoration and wiring, and can be used for its intended purpose.

The price for change houses and hozbloki from sandwich panels is changing enough wide price range. The final cost is affected by the built area, wall thickness, equipment, and materials used. If the building is designed for household needs, comfort is unimportant, and the installation of a plastic bag can be waived by replacing it with a blank window.

It might be interesting! In the article on the following link read about 3-D scrap in Holland.

Conclusion

The lifetime of a utility block from sandwich panels depends largely on the quality of the modules and on the installation technology. In the production of high-quality panels, galvanized steel is used, protected by a corrosion-resistant polymer layer, and the panels themselves are covered with plastic wrap that protects the surface during transportation.

The treatment of welds on the frame with protective enamel and rust converter is considered a professional approach. To prevent heat loss, panel joints are treated with foam. The finished product, mounted with the technology, is designed for 25-30 years of operation; The warranty period for different companies can be from one to three years.

Rate this article, we tried for you