The question of how to insulate a frame house, in those countries from which this technology came to us, is usually not worth it - it is believed that it is sufficiently insulated at the construction level. Our winters are very harsh - in the central part of the country the frosts are much stronger than at the same latitude in Europe or North America, so you have to warm even the frame houses, the design of which was originally provided for a layer of insulation.

Another insulation layer for our climate will not be “superfluous”

Choice of insulation for a frame house

Before in order to insulate the frame house from the outside, it is necessary to find out which insulation materials were used inside the walls. And already focusing on their properties, choose the scheme of insulation. This dependence is determined at the level of standards, where it is expressly stated that the materials and the external insulation scheme should not create conditions for wetting the wall itself. What does this mean?

It is estimated that per day, during the life of one person, up to 4 liters of water evaporates indoors: cooking, washing, hygiene, wet cleaning, pets and houseplants. The main part should be eroded due to ventilation, but another part of the moisture will penetrate into the building envelope.

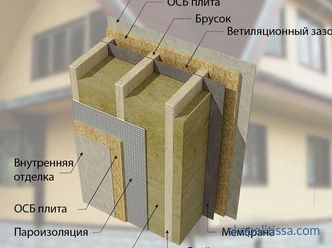

The standard wall scheme is a frame sheathed with thin-sheet materials on both sides, between which it is located to insulate. And so that it does not get wet, it is protected from inside by a vapor-tight membrane, from the outside - by a wind-proof and waterproofing film capable of “letting through” water vapor.

The standard layout of the facade of a frame house

If you use heat insulation with vapor permeability lower than that of the main insulation outside, the diffusion process will be broken ( removal) of water vapor to the street.

Three types of materials are used in the construction of the wall of the frame house:

-

polystyrene foam;

-

polyurethane foam (mainly in CIP panels) ;

-

mineral wool.

Polymer insulators have approximately the same vapor permeability, and it is low.

Note . The exception is PVC foam, but it is an expensive heater, which is used to insulate the hulls of yachts and other small vessels of the elite class.

If the frame house is being insulated with mineral wool, the scheme should take into account that this is a “breathing” material, but hygroscopic. The latter property is compensated by the fact that the fibrous structure (as opposed to the cellular one) just as easily gives off moisture as it absorbs. Subject to its free weathering.

Conclusion:

-

If foam polystyrene or polyurethane foam is laid inside the wall, the warming of the frame house can be done outside with any material.

-

If there is mineral wool inside, then only it can stand outside. As an alternative, ecowool or open-cell sprayed polyurethane foam, which have approximately the same vapor permeability coefficient.

It is advisable to warm the frame house outside and inside

Properties, advantages and disadvantages of heat insulators

Each type of insulation has a certain "set" of properties that affect the choice. About vapor permeability was mentioned above. It is necessary to focus on other qualities and differences.

Density

What is the density of insulation for the walls of a frame house, in addition to direct insulation, also affects the method of fastening. When using insulation with fastening sheets or mats inside the frame (lathing), there are no hard requirements for strength.

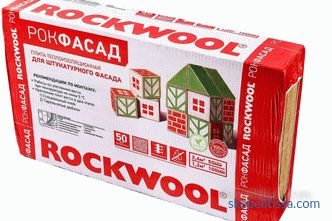

Stone wool . If we are talking about stone wool, then it should not be too loose - so as not to slip and wrinkle in a vertical structure. In ventilated facades, its density can start from 50 kg / m³.

When choosing a wet facade technology with a thin layer of light plaster, mineral wool should have a density not lower than 85 kg / m³. For heavy plaster - from 125 kg / m³.

Note . The division of the plaster is rather arbitrary. Up to 1500 kg / m³ are considered light, over heavy ones are considered.

If we consider that the density of cement is 1100-1300 kg / m³, and that of acrylic polymers is about 1200 kg / m³, then the main factor affecting the "gravity" is fillers. For decorative facade plaster usually use large quartz sand, screenings and stone chips, which provide higher strength to mechanical stress, but increase the specific gravity. Therefore, most of its species are heavy.

Reputable manufacturers already on the packaging indicate the purpose and methods of fastening stone wool

Styrofoam . With the choice of density polystyrene a little easier. When external insulation it is used either according to the "wet" facade, or as part of thermopanels. And here it is usually about PSB-S-25 or PSB-S-35. The second option is preferable - stronger, with almost the same thermal conductivity.

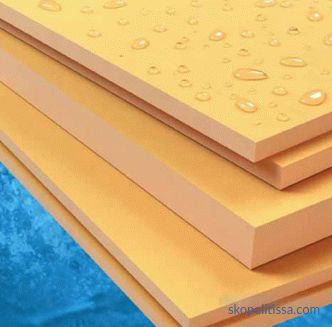

Extruded polystyrene , used for facade insulation, has a density of 35 kg / m³. But thanks to the cellular structure with a monolithic "skeleton" (and not glued together from individual microcapsules), its strength is much higher than that of the conventional foam PSP-C-35.

Extruded polystyrene is not susceptible to the effects of water

PU foam (polyurethane foam) . There are two types of sprayed PPU: with open cells and closed cells.

Open-celled polyurethane foam refers to lightweight insulation (9-11 kg / m³). According to its properties, it is similar to mineral wool: high vapor permeability and almost the same coefficient of thermal conductivity. It can only be used when spraying between the elements of the frame or crates, followed by paneling. But it is more expensive than mineral wool.

Closed-cell sprayed foam for facade insulation has a density of 28-32 kg / m³. He is already able to withstand a layer of finishing plaster and has the lowest thermal conductivity among all types of insulation.

On our website you can find contacts of construction companies that offer home insulation services. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Thermal conductivity

The lower the thermal conductivity, the better the thermal insulation properties of the material. For calculations, coefficients are used, fixed at the level of standards. Although manufacturers often indicate the characteristics that were obtained during laboratory tests, and they always differ for the better. However, when calculating according to standard indicators, you can be sure that it will not be worse.

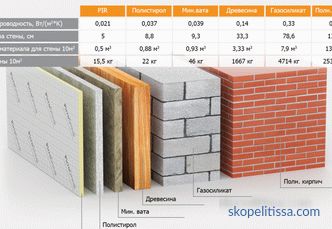

Comparison of thermal conductivity of various materials

Both two-component and single-component PPU are considered the best thermal insulation materials. Their thermal conductivity according to some sources is not higher, and sometimes lower than that of dry air - 0. 02-0. 023 W / m * deg. Polystyrene heaters have the same coefficient in the range 0. 031-0. 38, and mineral wool - 0. 048-0. 07.

Other characteristics affecting the choice of

Water absorption indicates the tendency of the material to get wet. The best performance here in extruded polystyrene foam and closed cell sprayed foam - about 2%.

The next in the list is polystyrene foam - up to 4%.

Mineral wool (including stone wool) - up to 70%. Ecowool when wet can increase its weight several times. But after drying, they restore their insulating properties.

What kind of thermal insulation is better: based on stone wool or fiberglass, discussed in the video:

If we talk about the cost of insulation , the most expensive technologies are ecowool spraying and PU foam "In the middle" - hinged facades with stone wool. Then - insulation using XPS. And the most accessible type is “wet facade” with expanded polystyrene.

It would seem that the insulation of a frame house with foam outside and inside the walls should be the most popular technology - low cost and water absorption with high thermal insulation properties.

For brick and monolithic houses, this is in fact the most common material. And the scheme of warming the walls of a frame house, like wooden, first of all must take into account the fire safety of materials and their environmental properties.

Foam insulation is incredibly popular

When polymeric insulation is “surrounded” by non-combustible materials from all sides (brick, concrete, building blocks, plaster), and he himself belongs to low-combustible and self-extinguishing, then such insulation is safe for residents. But if the supporting structure of the house is made of wood, the foam is dangerous - in case of fire, it begins to melt and release dangerous gases to life.

Therefore, non-combustible mineral wool is more often chosen for internal warming of frame walls, and as a result of the requirements for vapor permeability of materials, it is used outside.

It might be interesting! In the article on the following link, read about how to insulate a shield house for winter living.

Warming of a frame house outside with mineral wool

Of the three types of mineral wool, stone (basalt) wool is used for warming residential buildings. When working with glass, quite a lot of microscopic fragments of fiberglass are formed, which are dangerous to the respiratory organs of workers during the installation of insulation and residents at the first time after the settlement. Slag is not recommended to use because of its low environmental qualities.

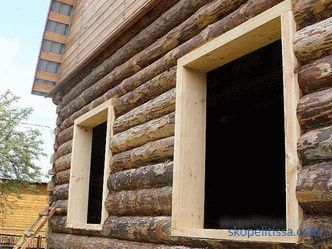

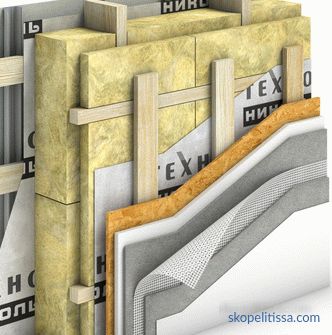

Scheme of thermal insulation of walls of a frame house with an additional outer layer

With external insulation of mineral wool, the technology of the ventilated facade is somewhat different from the usual scheme. For a house made of brick, building blocks, logs or timber, the crate is fixed to the wall.The frame house has no wall as such in the conventional sense. What is the point of stitching the frame outside the OSB with a plate, and for the next layer of insulation, mount the sheathing on top, if it can be immediately mounted on the supporting racks.

This is also justified by the fact that the “fresh” OSB slab has a vapor permeability lower than that of stone wool. Therefore, ideally, the “cake” of the correct warming of a frame house with mineral wool looks like this:

-

interior finish (with lathing for panels);

-

vapor barrier ;

-

frame with insulation;

-

lathing for the outer layer of mineral wool;

-

wind-proof vapor-permeable diaphragm:

-

counter lattice to create a ventilated gap;

-

front cladding and trim.

Insulation outside with polymeric materials

With the construction technology of frame houses made of CIP panels, they still at the manufacturing stage have foam polystyrene or rigid polyurethane foam laid as an internal insulation.

This is how a factory-made sandwich panel

It might be interesting! Read the article in the following link about what to insulate the walls of the house from the inside.

In addition, the usual assembly technology of the "sandwich" on site allows the use of polymer insulators in the form of plates or sprayed liquid polyurethane.

PU foam application as an internal insulation for a frame house

In both cases, the wall has a “finished” structure with double-sided sheeting. And it is possible to carry out warming of the frame house with foam plastic on the outside according to the wet-facade technology.

The content of work has a standard appearance:

-

A horizontal level is beaten along the base, on which the starting level is fixed.

-

With the help of glue fix the first row of foam plates.

-

The second row is fixed with an offset of at least 20 cm relative to the first.

You cannot mount the XPS in this way. Intersecting horizontal and vertical seams - the cause of the facade plaster cracks.

-

The corners of the openings should not be on the seams and at the intersections of the seams.

-

Each sheet is additionally fixed with plastic dish-shaped dowels 5 pieces per sheet.

The plastic dowel does not form a "cold bridge"

-

The foam is applied a layer of glue with a thickness of 3 mm; a reinforcing mesh is attached to it and covered with another layer of glue.

-

Carry out the finishing finish with plaster.

Another way to use foam for outdoor insulation of a frame house is a thermopanel with a clinker tile.

Thermopanels - insulation plus brick finishing

Sprayed insulation

To some extent this technology It resembles putting plaster on beacons - on the walls they fill vertical slats, between which they sprayed polyurethane foam or ecowool.

The frame house, insulated with polyurethane foam outside, is ready for decoration of the facade.

After the polyurethane foam "hardens", its surplus is cut off special manual electropower or electric saw. From above, you can either install the front panels, or apply a layer of decorative plaster.

You can familiarize yourself with the technique of cutting excess PPU with an electric saw in the video material:

When ekvatoy insulation of frame walls, it is sewn panels .

It may be interesting! In the article on the following link read about how to insulate the roof of a house.

Conclusion

Technically, it is easy to perform warming of a frame house. If you do not consider the option of thermal insulation sprayed insulation, then it does not need any special equipment. But in each case, it is necessary to carefully calculate the density of insulation for the walls of the frame house, plus, there are always technological "nuances" that you need to know - otherwise the result will not give the expected effect. Therefore, it is better that professionals do the home insulation.