For lovers who spend all their free time at a car, the inner lining of the garage takes on particular importance. The article offers an overview of popular materials that are suitable for finishing the garage inside, and the criteria for choosing the walls, floor and ceiling of the garage room. After reading the article, you can choose the material that is best suited for the conditions of your garage.

Finishing materials: 6 operational requirements

The modern construction market is full of various finishing materials with a wide range of prices and characteristics. When choosing how to trim the walls of the garage inside, it is important to remember that the garage is a technical building, so the lining is chosen according to the specific use. Materials intended for interior decoration must meet the following performance requirements:

-

Mechanical strength . The coating of walls and ceiling should be as resistant as possible to mechanical loads of any type, both to impacts and to deformations (weight loads).

-

Resistance to chemical agents . Garage - a place of storage and use of a variety of fuels and lubricants (fuel and lubricants), intended for the repair and care of the car. Most of them (acids, oils, greases, fuels) are chemically active compounds and dirty the floor and walls more often than we would like. Resistance to chemical attack is an important condition for the choice of material.

-

Fire resistance . Most of the products used for car maintenance are flammable substances. The logical step will be the choice of the most fire-resistant cladding.

-

Y resistance to temperature fluctuations . Especially important parameter if the owner does not plan to install heating. In this case, the lining will have to withstand multiple fluctuations during one season, which is far from all materials.

-

Easy care . Strong pollution is not uncommon for a garage room, so the weak absorbency of dirt, car chemicals and odors, as well as ease of care for the surface of the floor and walls (and sometimes the ceiling) becomes a valuable quality.

-

Easy to update . Well, if there is a possibility of updating or additional protection of the material of the walls with the help of paints and varnishes.

On our site you can find contacts of construction companies that offer the service of building turnkey small architectural forms. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Wall decoration: the choice of material

Despite the severe restrictions imposed on the cladding, the question of how better to decorate the walls in the garage does not cause great difficulties. There is a considerable amount of materials that meet all the above requirements, allowing you to design a garage is not only practical, but also aesthetically attractive. Garage wall cladding can be done using the following materials:

Ceramic tile

Ceramic tile optimally matches the conditions of operation in a garage box; Among its positive qualities are the following parameters:

-

Physical properties . Fire resistance, frost and water resistance.

-

Strength . Tiled flooring withstands high loads.

-

Easy care . Ceramics can be cleaned from contamination dry and with the use of detergents (including compositions with abrasives).

-

Wide choice . The best option is clinker (especially for the floor) or porcelain stoneware, the number of varieties of which is practically inexhaustible. Choice limited matte (non-slip) material.

-

Aesthetic appeal .

The use of ceramic tiles has its own characteristics:

-

Weight . Ceramics is a fairly heavy material, so it is recommended to lay it on the walls of brick or concrete. The process of laying small piece of material on the cement mortar stretches over time.

-

Price of the material and its installation . The main limiting factor when choosing the interior facing of the garage.

-

Possibility of saving . High-quality clinker can be used as a floor covering, and for the walls you can choose a low-cost ceramic tile (or make a lower, more vulnerable layer, from clinker, and the top one from porcelain stoneware). The walls are often finished with tiles at an incomplete height (1.5 m), above them they are plastered and painted.

Plaster

Solving the question than sheath the garage from the inside cheap, car owners sooner or later stop on the idea of plastering. The method attracts with its efficiency and speed of implementation, and the surface of the walls acquires strength, fire resistance and durability. When choosing this method, consider the following features:

-

Walls . Best of all, plaster clings to concrete, brick, aerated concrete walls.

-

Selection of the base . The preference is given to solutions on a cement and sand basis.

-

Staining . After the plastered surface dries, it is painted in the selected color. It is recommended to use facade paints - they have dirt-and water-repellent properties, are easy to clean and have low resistance to chemical agents.

The limitation of the method is the need for professional skills in its implementation. Otherwise, the defects of the work will appear at the first significant temperature drops (swelling, flaking and cracks on the surface).

It might be interesting! In the article on the following link read about plaster for aerated concrete.

Paneling

Paneling is a popular method of interior decoration; it makes the room attractive, gives the lived-in look and is perfect if you need thermal insulation. When you know how to use the garage room, the choice of material is greatly simplified. If your garage will combine the functions of a service station and a workshop, you will need a professional flooring with its strength and incombustibility. If you plan to carry out only simple maintenance yourself, you can stop the choice on PVC. If the garage is a place to restore spiritual strength with parallel glossing on an iron friend, there are no restrictions on the choice of material. The garage is finished with the following types of panel materials:

PVC cladding

Interior walls and ceilings with PVC panels are widespread and suitable for many owners of capital garages; Its advantages include the following qualities:

-

Accessibility . Pleasant value for money.

-

Physical properties . The material is moisture resistant, does not require additional processing (painting).

-

Easy installation and unpretentious care.

-

Low weight . Covering the door with plastic does not increase the weight of the leaves, does not load the hinges and the frame design.

-

Use of frame for fixing panels. It can be used to insulate buildings, for example, with mineral wool.

-

Cheap repair in case of damage. It is easy to replace one part without disassembling the whole structure.

The disadvantages of using vinyl siding as a garage finish include:

-

Low mechanical strength . Upon impact, the panel is easily deformed.

-

Sensitivity to temperature differences . You can purchase more reliable (and expensive) panels for facade works or special ones for the garage. This material is designed for the fact that the garage is often not heated, and therefore has improved characteristics.

About the non-standard approach to the design of tiled walls in the following video:

Wooden lining

Basic The raw material for the production of natural lining is softwood, usually pine. This material is cheap, convenient for processing, safe for health. Covering the garage clapboard will justify itself if the wood has undergone a preliminary protective treatment with antiseptic and fire retardant. The positive properties of wooden lining include the following properties:

-

Environmental cleanliness and durability.

-

Accessibility for a wide range of consumers.

-

Simple and reliable installation . The wall paneling is placed on a wooden crate or on a plastered wall. The parts have a notch-tongue joint system, so that they fit snugly together.

-

Strength and frost resistance .

-

Resistance to mechanical stress .

-

Natural texture and a large selection of natural shades.

The disadvantages of wooden clapboard include its features:

-

High hygroscopicity .

-

Susceptibility to bio-threat . Indoors with high humidity are likely to develop mold and insect pests.

-

Flammability . Slightly decreases after using flame retardant.

-

Complicated care . It may be difficult to clean the wall from oil stains, therefore it is recommended to cover the wood paneling with a layer of varnish that protects the wood from being absorbed.

It might be interesting! In the article at the following link you can read about wall cladding in a wooden house.

Plasterboard plating

When pondering over what to trim the garage inside, many people pay attention to drywall (dry plaster). For finishing the garage room it is recommended to use a material with improved moisture and fire resistance properties. Such sheets are designated GKLVO, characteristic gray-green color and red marking. The use of drywall has obvious advantages:

-

Affordable price .

-

Low weight of material. Sheets are mounted on a special adhesive solution or metal frame. The second method is convenient when the walls are uneven or need warming.

About the wall paneling with wooden clapboard in the following video:

-

Easy Installation with a minimum of construction waste (compared to classic plaster).

-

Use as base . On the material (if it was used to align the walls), you can fix the ceramic tile or put a relief plaster.

-

Use as a partition . Plasterboard, fixed on the frame, suitable if you want to allocate space in the garage for a mini-warehouse or changing room.

-

Changing the shape . Drywall is suitable for the formation of not only flat, but also the arch structure (after preliminary preparation).

The facing of the garage walls and plasterboard ceiling installed on the frame has its disadvantages:

-

It is unsuitable for a small room. The frame reduces the already small free space.

-

Low impact resistance of walls. If over plasterboard is planned to be covered with a durable material (for example, a ceramic-tile), the disadvantage disappears.

It might be interesting! Building a major garage provides high-quality insulation. In the article on the following link, read about how to choose material for internal insulation.

Cladding with OSB

Plywood and other wood-chip materials can be found as an option for finishing garage walls. OSP (oriented strand board) sheets, which are made of a mixture of chopped wood and various bonding agents, are well suited for the installation of heat-insulated walls. For covering garage walls (and the ceiling), the best option is sheets marked OSP-3 or OSP-4. OSP-3 material is the most common choice for a garage finish. It is characterized by good strength and medium moisture resistance, therefore it needs additional moisture-proof treatment. OSP-4 is a more durable version with the following advantages:

-

Long service life .

-

Durability and resistance to temperature differences .

-

Good moisture protection . The material is not deformed in conditions of high humidity.

-

Mold Resistance (contains antiseptic additives as a part).

On the varieties of garage floor coverings in the following video:

Interior finish of the garage with OSB panels has disadvantages:

-

The material belongs to the highest category of combustibility (G4).

-

Evaporation of harmful substances . The composition of the sheets includes formaldehyde resins, the evaporation of which is harmful to health, but, with the ventilation device, may be of an acceptable level.

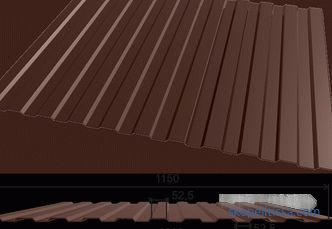

Profiled

One of the practical and cheap plating options is profiled - profiled steel sheet protected by a polymer or paint and varnish coating. As well as lining, it is convenient to mount it on a wooden crate. Decking has the following features:

-

Durability and incombustibility.

-

Resistance to temperature changes and to aggressive environments.

-

Quick installation , provided with large material sizes.

-

The main lack of sheeting - susceptibility to corrosion .

-

Replacing a bent professional sheet will cost more expensive than repairing vinyl siding (PVC panel).

It might be interesting! In the article next read the link about roofing: sheet size and price.

Finishing of the floor and ceiling

The roof for garages is usually made flat. This saves money and effort, but at the same time increases the likelihood of leakage when the water after the rain lingers on a horizontal surface.Therefore, the decorative headlining in the garage proceed after its waterproofing. One of the most common ways is plastering the ceiling, followed by painting. Since the ceiling is not subject to damage, the choice is often in favor of MDF or PVC panels. This is a popular and practical option that allows (when using the frame) to conduct insulation and hide communication systems.

About the intricacies of the self-leveling floor in the following video:

Special requirements are placed on the floor covering in the garage, it must withstand considerable and regular weight loads from car. The following flooring options are preferred:

-

Painted concrete floor . A popular option that easily withstands the weight of the car. The concrete floor covered with a primer weakly absorbs spilled auto-chemistry, does not collect dust and is resistant to abrasion. Although the process of arranging a concrete floor can not be called fast, many motorists stop on it due to low cost and simplicity of technology.

-

Tile . Garage floor of ceramic tiles (or keramonranita) looks neat and often original. The coating is advantageous for its durability, uncomplicated care and resistance to fuels and lubricants. The limiter of tile use is its high cost and rather time-consuming process of creating a tile covering (including mandatory waterproofing).

-

Cast concrete . Impact resistant coating with an ideally flat surface that is as strong as a classic concrete floor. One of the most successful coatings for the garage room, because it has frost resistance and high resistance to chemical environments. The disadvantage of the method is the high price of the composition, which is why the self-leveling floor cannot be called an economical option. Another subtlety - the base under the fill should be perfectly smooth, which is not always achievable.

-

Wooden floor . The choice in favor of a wooden flooring (flooring) is not made often, although the basis for such a floor does not need to be leveled. Many believe that the disadvantages of such a floor more than the advantages - flammability, a high degree of absorption and low strength. Proponents argue that wood flooring is much nicer and healthier to work; besides, wood (unlike concrete) does not form dust.

It might be interesting! In the article on The following link read about the projects of houses with a garage.

Conclusion

Interior decoration is an important part of the arrangement of the garage room. Properly selected finishing materials maintain cleanliness and order, as well as help to extend the life of the vehicle.