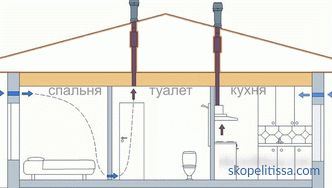

The new SNiP on thermal protection, commissioned since 2003, imposes strict requirements on the thermal insulation of wooden walls. If earlier a house from a bar with a thickness of 200 mm or a rounded log with a diameter of 280 mm “fit” in the standards, now they no longer meet the new standard. Of course, the owners of existing buildings may not do anything, but we must bear in mind that investing in the insulation of a wooden house is cheap compared to the bills for several years for heating and air conditioning. Consider how and what to insulate outside a wooden house, so that it is of high quality, and the house does not lose its environmental properties.

Methods of insulation

According to current regulations, there are three types of external wall designs according to the number of layers .

Single Layer. Bearing and heat-insulating properties are combined at the level of the building material of the building envelope. For stone houses, you can give an example of a porous large-format ceramic block or a foam concrete block. For frame wooden houses it is a CIP panel.

As a reference! New standards are so tough that these walls may need warming with insufficient thickness of the base material.

Three-layer. Walls, in which construction materials with a thickness of at least 50 mm, fixed to the base with dotted ties, serve as an outer layer with respect to insulation. A classic example is a warmed brick-faced house. You can find such examples of the construction of enclosing walls for wooden houses. And in this case we are talking about facing with bricks, since the paneling by imitation of a bar or block house is by definition not suitable because of the thickness of the outer layer.

Double-layer with external thermal insulation. This is the most common method of warming a wooden house. Moreover, such a design can be without an air gap or with a ventilated air gap.

We can talk about four options for how to properly heat a wooden house outside:

-

"wet facade";

-

hinged facade;

-

sprayed thermal insulation

-

brick cladding.

The regulations specify another type of design - with a non-ventilated air gap. But such insulation of a wooden house is not recommended due to the nature of the material itself.

Features of wood as wall material

Regardless of the structural materials of the walls, it is important to follow the following rules formulated at the SNiP level for building insulation:

-

thermal insulation is necessary reliably protect from moisture penetration into it;

-

water vapor access to the insulation should be as limited as possible;

-

layers should ensure the drying of the structure and prevent in her accumulation of moisture.

The first rule is technically simple to execute. The exterior finish protects the properties from contact with atmospheric moisture; its properties can be enhanced with the help of a waterproofing membrane.

Another way to protect the tree from moisture in the video:

Protection against water vapor penetrating from inside the house is provided by appropriate vapor-tight membranes that do not interfere with the "breathing" of wooden walls , but detain larger water molecules that are in the warm air of the heated room. And here there is some contradiction with the requirement for the location of the layers, which should ensure the erosion of water vapor from the structure.

Wood is an unusual building material - it easily absorbs atmospheric moisture and gives it away just as easily. But if we fix a vapor-tight membrane outside the wall, the natural moisture transfer will be disturbed, and this is bad for wooden structures, which, when wet, begin to rot. Therefore, many experts advise for wooden walls not to be used outside as a waterproofing film (only membranes), and to discard vapor barrier membranes altogether, so as not to interfere with water vapor to erode from the wall and insulation in both directions.

Note! If you look at the websites of leading manufacturers of ready-made systems for plastering and hinged facades (Knauf, Ceresit, Scanroc), none of them have a vapor-tight membrane in the “cake” structure to protect the insulation .

And these same requirements for drying the structure impose restrictions on the choice of insulation .

On our site you can find contacts of construction companies that offer a house insulation service.Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Selection of insulation for the walls of a wooden house

None of the regulatory documents contains a direct ban on the use of foam plastic. Moreover, expanded polystyrene is specified as a heater for a wooden house in all permissible types of structures. But its vapor permeability is much less than that of wood across fibers (not to mention the direction along the fibers). And if it is used as heat insulation, it will completely block the weathering of water vapor from the wooden wall to the outside.

Penoplex, which is extruded polystyrene foam, differs from the usual only in its production technology, and its vapor permeability is just as low. Therefore, this popular heat-insulating material "wet facade" is not suitable for two-layer insulation of wooden walls.

The same arguments "work" against the use of sprayed foam. And if during the installation of polystyrene foam there are any seams and gaps, then the seamless “shell” of vapor-proof heat insulation will completely eliminate the possibility of weathering the excess moisture outside.

Mineral wool best meets the conditions for "drying the structure." If we talk about fire safety, then this parameter is most suitable for insulation of a wooden house. Of the three types of mineral wool, stone is commonly used. It is more difficult to work with glass wool - when fitting and mounting, fine chips are formed from fragments of fiberglass, which are dangerous to the skin and respiratory tract. A slag is not recommended for insulation of residential buildings due to low environmental qualities.

Spray heat insulation is an eco-friendly product with wet wall technology.

Preparatory stage

Before warming wooden house outside, the facade must be prepared.

There is a standard set of activities for any type of building, which consists in clearing the surface of the hanging elements. And there are works that are typical for a wooden house - checking the condition of mezhventsovyh heaters, caulking iron (if necessary) and treatment with antiseptic.

Preparatory work should be carried out in dry weather. This is especially important for the impregnation of the top layer of wood with an antiseptic. The treatment process itself consists in applying the solution according to the “staining” method, and if the capillaries of the upper layer contain water, the antiseptic will not be absorbed properly into the wood.

It can be interesting! In the article on the following link, read about the thickness of the walls of a frame house for year-round living.

Features of the “wet facade”

When fixing mineral wool to the wall in the “wet facade” system, glue mortar and mechanical fasteners are used. Moreover, the glue plays a major role, since the number of metal heat-conducting inclusions in thermal insulation should be limited. And so that the slabs of hard stone wool mats can be securely fixed, the wall must be sufficiently even or have slight differences in the “relief” in height, which can be fixed with a layer of adhesive. This condition is met only at home from a bar.

The wall surface of the log must be leveled. You can do this with OSB, moisture-resistant plywood or plasterboard for exterior finish (Knauf recently presented this type of plasterboard). But plywood and OSB do not meet the requirements for vapor permeability of the front finish of a wooden house, and in any case, lathing is necessary for alignment. And the use of lathing and additional materials negates the advantage of the "wet facade" over the ventilated one - a relatively low cost.

Use "wet facade" for additional warming of frame houses. And if one of the types of polymeric materials was used as the internal insulation of the thin-sheet construction of the enclosing surfaces, then foam plastic can be used for external insulation - it will not impair the vapor permeability of the walls.

There are some peculiarities in the methods of fixing insulation to wooden walls, when screws are used instead of dowels , and glue solution is highly elastic.

Otherwise, the insulation technology has a standard sequence of works:

-

The starting bar is attached along the perimeter of the plinth (grillage).

-

Mount the bottom row of stone wool mats. Use glue and at least 5 pcs. screws on 1 m².

-

When installing the next rows, the vertical seams move not less than 20 cm.

-

The openings of windows and doors in the corners should not have intersecting seams sheets of insulation.

-

The surface is reinforced with fiberglass mesh, and the corners with a perforated corner. For fixing the reinforcing elements use adhesive solution.

-

A layer of mortar is again applied over the mesh (total thickness should be about 6 cm), level the surface, and after drying, grind.

-

Plaster and paint the facade.

Clearly about the wet facade on the video:

How to warm a wooden house with foam plastic

If you wish, you can find examples of using foam plastic, to warm the wooden house outside. And there is a technology that does not impair the "breathing" properties of the walls and the level of comfort, which is provided by natural gas exchange between the rooms and the street. This is achieved by creating a ventilated gap between the insulation and the wall. And in this case it does not matter what the walls are made of - a bar or a log.

. :

-

main wall;

-

crate from a bar not less than 60 mm high (the minimum size for a ventilated gap);

-

fixing insulation to the batten (expanded polystyrene, EPS);

-

finishing with facade panels or a layer of plaster reinforced with fiberglass mesh.

But once again it must be emphasized that this method of insulation will not be cheaper than a ventilated facade. In addition, it violates the recommendations of the regulations, which states that the air gap should be placed between the insulation and the outer layer.

What happens if insulating with polystyrene is wrong - in the video:

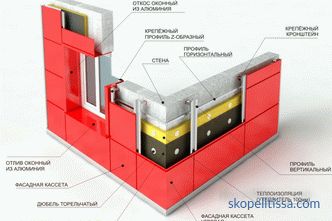

Features of the curtain wall

In this case, the requirements for the strength of the insulation surface for tearing are not high, as in the wet facade, therefore the density of the mats may be less than 125 kg / m³, but higher than 80 kg / m³.

Attention! When choosing how to insulate a wooden house outside, you need to know that the use of rolled mineral wool in curtain walls is not recommended by regulatory documents.

There are already ready systems of hinged facades with their own mounting subsystem, a set of panels and fasteners. The only drawback of such systems is the need for individual adjustment to the specific geometry of the house and walls. As a rule, these systems are designed for houses made of bricks or building blocks, and as cladding they use aluminum sandwich panels, artificial stone, and porcelain stoneware.

Imitation of a bar, a block house, a planken, a siding are usually used for facing of wooden houses. That is, those materials that are more in line with the aesthetics of a wooden house.

for cladding. wooden timber - it is easy to adapt it to the surface of the walls, it is easier to fix, it does not change dimensions when the temperature drops and does not serve as a "cold bridge".

The only drawback of wooden structures is low resistance to moisture. Therefore, the elements of the batten and finishing panels made of natural wood must be treated with antiseptic before installation.

It might be interesting! In the article on the following link, read about how to insulate a house from a bar from the inside.

As a result - what else can you consider options

The article described only two of the most common ways how to conduct insulation of a wooden house outside. The better in your case, other options need to be discussed with a developer who knows the local conditions. The use of eco-wool has not yet become widespread, although the technology is quite simple - mounting the lathing to the wall, applying to the surface with the help of special equipment insulation in a "wet" form (mixed with glue), covering the facade panels on the lathing. Brick cladding on flexible connections proceeds according to the same rules as for a stone house, with the only restriction on the choice of insulation - the use of mineral wool only.

Despite the seeming simplicity of the whole process, when installing any kind of insulation there are a sufficient number of pitfalls that must be taken into account so that all work is not done in vain. If there is no experience, then it is always better to invite a professional, especially since self-respecting developers do all the work under the contract and give a guarantee.