Today we will talk about such a popular building material as profiled. About its advantages and disadvantages, where it is used, and the installation technology on the roofs. After reading the article, you will not need to look for information in other sources. But the main focus here will be on information about the roof of corrugated board.

What is profiled

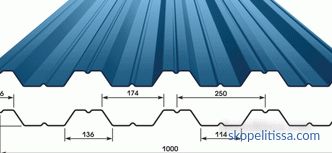

This is a galvanized steel sheet with a thickness of 0.35 to 1 , 2 mm, which is formed by cold rolling in a wave-like material. This is the way to increase the carrying capacity of sheets. The shape of the corrugations may be wavy or trapezoid.

Profiled sheeting is made only of galvanized steel, which has high moisture-proof properties that resist metal corrosion processes, plus increasing the service life of the material. Today, manufacturers offer painted profiled sheets or coated with a polymer layer. This, firstly, additionally increases the service life of professional sheets, and secondly, it becomes possible to choose a coating with a specific color scheme.

The main parameters of sheeting:

-

sheet thickness;

-

profile height;

-

profile width;

-

working width of the material itself.

Advantages and disadvantages

Denote the advantages of the material:

-

low specific weight, which facilitates the operations performed with it;

-

simple installation process;

-

low price compared with other roofing;

-

variety of colors;

-

aesthetic appearance of the roof.

As for the minuses:

-

decking - a metal product, so it has high thermal conductivity, which requires a roof insulation;

-

low sound insulation.

On our site you can find contacts of construction companies that offer the service of designing and repairing roofing. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Criteria for choosing a professional flooring for a roof

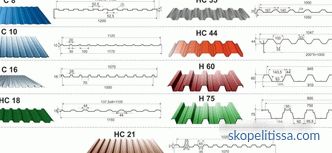

The construction of a roof from a professional flooring begins with the selection of the roofing material itself. Today, manufacturers offer three types of profiled sheets:

-

Marking "H" denotes the bearing type, used just to cover the roof.

-

With the "C" marking, wall models are produced, which are most often used for the construction of barrier structures and cladding for wall and ceiling surfaces. Although we must pay tribute to the fact that the wall profiled sheet is also used for the construction of roofs of light canopies, terraces and arbors.

-

“NN” is a universal form used in any building structures, and on roofs as well.

That is, it turns out that any of the above varieties can be used to cover roofing But there is one important nuance here. If you walk so that the roof erected from corrugated flooring lasts a long time and withstands serious loads, then you must choose a material with a metal sheet thickness of at least 0.55 mm.

Please note that this is the thickness of the metal, which does not include paint or polymer layer. And if you make a measurement with a caliper in the store and it will be 0.55 mm, then you should know that the actual thickness will be 0.5. Also note that this size is not specified separately in the certificate of conformity. It is indicated in the product labeling. For example, H75-750-0. 9. It is “0.9” that is the thickness of the metal.

As regards the dimensions of the profile (height and width), the larger they are, the higher the carrying capacity of the material. But at the same time, the overall dimensions of the professional sheets are reduced. So, it will be necessary to acquire more elements of the roof covering. For example, professional flooring H75-750, where 750 is the width of the sheet. Or C40-1000, where 1000 - width. That is, the carrying capacity of the roofing material increases, the area of the coating itself decreases.

Rules and nuances of installation of profiled sheets on the roof

Installation of the roof of corrugated board begins with the acquisition of the required amount of material. For example, if they are covered with a gable roof, then it is necessary to measure the width of the slope and divide it by the working width of the sheet. This is the amount per slope. In this case, the length of the professional sheets is not taken into account, because they are issued either six-meter or twelve-meter. At the same time, the store will trim the panels to the required length dimensions in increments of 50 cm, ranging from 0.5 m and more.

This is another great advantage of roof covering roofing technology. It provides minimal waste. And if you correctly measure the length of the slope, then the roof covering will be without joints.The latter are places of possible leakage, if it is incorrect to take into account the angle of inclination of the slope and the size of the overlap of two adjacent elements.

We turn to the roofing of the profiled sheet on the wooden crates.

Lathing for corrugated

For this, cutting boards are used with a thickness of 25-35 mm and a width of 100 mm. The main parameter of the structure is the distance between the elements. It is determined by the size of the profiled sheeting. The greater the carrying capacity, the greater the distance in the construction of the batten. For example, for a professional sheet H75 the distance between the boards is 1.5-2 m, for C40 the distance is 0.5-0.6 m.

The process of assembling the lathing for professional flooring in the video:

This can be interesting! In the article, on the following link, read about crate for siding - types and features of the materials used.

Roof covering

First of all, roofing material should be raised to the roof. If the house is single-storey, then the easiest way is to install two bars or two boards 50 mm thick with a distance between them less than the width of the flooring. The photo below shows how to install the boards.

The lifting is done as follows:

-

in a single sheet at the edge in the middle make a through hole;

-

it is placed on the boards so that the hole turned out to be at the very bottom;

-

a couple more sheets can be put on top;

-

a hook tied to a rope is inserted into the hole;

-

from the side of the roof they pull over the rope, from the bottom they push upwards with their hands.

The installation itself is carried out from either side of the ramp. The main task of the work producer is to set the sheets exactly on the bottom, that is, horizontally. Therefore it is important to accurately set the first sheet to be fixed. Fastening produce roofing screws with a wide cap. At the same time, the screws are not fully screwed in, leaving the opportunity to once again check the accuracy of the installation of corrugated flooring. And if everything is correct, then fasten the fasteners to the end.

The sheets themselves overlap with a displacement of one wave. This ensures reliable closing of the joint between the elements, which guarantees the absence of leaks.

Roof covering with separate sheets

If the roofing is made of corrugated flooring in short sheets (less than the length of the slopes), it is important - to carry out the installation correctly in terms of the choice of overlap sheets in the longitudinal direction. This parameter depends on the angle of slope of the slopes. Here the relationship is:

-

tilt 5-10 °, overlap 30 cm;

-

tilt 10-15 °, overlap 20 cm;

-

slope more than 15 °, overlap 17 cm.

Fixing rules

The rules for covering the roof with a professional flooring include positions associated with the correct fastening sheets to the crate.

-

Fastening to the crate is made through the lower wave.

-

The fastening of two sheets in the transverse overlap is made in the upper wave.

-

Self-tapping screws are screwed strictly perpendicular to the plane of the roof slope.

-

You can not pinch the fastener or hold it short, because in the first case it will cause the gasket to break, in the second case to its loose pressing. Both reasons - the appearance of leaks in the place of attachment of screws to the profiled sheets, which will lead to leaks.

-

The attachment points are along the upper and lower edges of the sheet through a wave, intermediate fixation over the rest of the area in 2-3 waves to each element of the sheathing.

It might be interesting! In the article, on the following link, read about the polycarbonate roof.

Installation and fastening of additional elements

Of the additional elements for the roof of profiled sheets, the ridge and pediment boards are used. Eaves levels are established before the professional flooring installation, and they fasten to rafter legs or the first lower element of an obreshetka.

The ridge is closed with a special element that is attached to the crate through the laid professional sheets. Fastening is made through the upper wave of the roofing material. The fastener pitch is 20-30 cm. The length of the ridge element is 3 m, therefore they are overlapped relative to each other with an offset of 10-15 cm.

The gable plates are installed with one goal - to protect the roof covering from the wind so that I could not penetrate under the profiled sheet and did not understand him with my strength. Plus, it provides the aesthetic side of the case, completeness of the roof structure. Attached gable strips to the profiled sheets in the upper extreme wave. If the gable beam is present in the roof structure, then so is it.

The standard length of the slats is 3 m, they are overlapped with an offset within 10 cm. The fastening step with self-tapping screws is 30-40 cm.

Useful tips

When choosing a decking for building a roof, it is necessary to choose it correctly according to the type of polymer layer. Manufacturers offer several polymers that cover profiled sheets.

| Polymeric material | Layer thickness, µm | Maximum service life, year |

|---|---|---|

| Polyester | 25 | 25 |

| Pural (polyurethane base) | 50 | 50 |

| Plastisol (base PVC polyvinyl chloride) | 200 | 50 |

| PVDF (20% acrylic, 80% polyvinyl fluoride) | 27 | 40 |

The thicker the protective polymer layer, the higher the price of corrugated flooring. It should be borne in mind that expensive roofing material must be used wisely. It has good technical characteristics, especially wear resistance and resistance to ultraviolet rays. Therefore, it is recommended to use such material in areas with active loads. For example, with the negative effects of air with a high concentration of salt (coastal areas), with a high concentration of acids and other active substances in the air (large industrial cities).

Installation of corrugated roofing:

It may be interesting! In the article, on the following link, read about the dimensions and the prices of corrugated roofing.

Conclusion

The correct choice of professional flooring used as a roofing material, plus its competent installation is a guarantee of long-term roof operation. In addition to the economic side of the case - you need to correctly calculate the required amount of roofing.