This article contains information about houses from a bar with a mansard. You will learn about the advantages of timber, as a building material and on what basis houses are being built from it - technologies for building the foundation, walls, and attic, which floor is better to choose for a wooden house. Also, at the end of the article there are the most successful layouts of log houses with an attic.

Characteristics of houses from a bar

To begin with, What are the advantages and disadvantages of buildings made of timber. This raw material has a lot of positive properties:

-

Wood is the most environmentally friendly building material , which not only does not emit any toxic substances, but also has a beneficial effect on health person

-

The tree is quite easily processed , so you can create very interesting and intricate spatial shapes and shapes from it.

-

Bar walls are very strong and durable , have low thermal conductivity and provide some of the best sound insulation performance.

-

With the right choice of materials and competent design, a house from a bar will eventually be the most economical housing option.

It is important to know what kind of timber is used for the construction of residential buildings. There are the following types of it:

Simple cut timber

Cut timber refers to sawn timber. This means that it is obtained after the machining of tree trunks. Coniferous varieties are most often used. Generally, if we talk about size, then the timber is any lumber, the side of which is more than 100 mm.

The section of the timber depends on its sawing. It may be square, round, rectangular, semicircular or D-shaped. The surface of the wood can be polished, and it can remain untreated.

Now about the positive sides of the trimmed timber:

-

This is a very profitable option , since the wall made of it is cheaper than from another material. At the same time, it is possible to achieve high energy efficiency by organizing an air gap between the wall and thermal insulation. The bonus of this method will be excellent ventilation of the walls, which will prevent the appearance of fungi.

-

The wall of the trimmed beam will “breathe” even with external insulation. This is a significant advantage over other materials, as when using, for example, frame technology because of the vapor barrier film creates a greenhouse effect. Therefore, log houses do not require extensive and complex ventilation.

-

The beam can be used without any external plating . The fact is that a tree with polished edges possesses rather high decorative qualities.

Due to the sufficient number of positive sides, more and more people choose cut timber for construction.

However, unfortunately, like any other material, the edged timber has its drawbacks:

-

The humidity values of wood change during the operation of the building. Therefore, wooden houses are prone to swelling or shrinkage. From here there can be an uneven change in the size of the structure, as well as the appearance of cracks and other defects.

-

The cut timber has low biological resistance . The fact is that it is a favorable environment for the activity of fungi. Without a quality treatment with antiseptics, a wooden house will not last long.

-

When using a non-planed timber, you will need interior and exterior walls, which will increase the final cost of the building.

Profiled beam

In many ways, this material is very similar to a cut timber. Raw material for its manufacture is also a log, which is processed using a special system of cutters, with the result that the output is a planned profile.

This is necessary not only for enhancing the decorative qualities, but also for better fit. Connection of bars is made at the expense of grooves and crests from below and from above. There may be two spikes along the edges or several along the entire length of the timber. In the joint between the rows fit insulation.

The sides, however, are usually machined to obtain a smooth surface, so they do not require any plating. With the help of profiled timber you can quickly build a high-quality log house.

Of the special advantages of the material, the following points should be noted:

-

Installation of walls of such material is much less labor-intensive .

-

Shrinkage of such material will be much less than that of the trimmed beam. When using the same raw chamber drying, this figure will be minimal.

-

The joint of such a bar is completely non-blown .

Now about the drawbacks of the profiled bar:

-

The house from it requires more investments than the same, but from cut timber.

-

If the profiled bar is badly dried, then it is more prone to warping .

-

This material has a higher thermal conductivity than a cut timber, which is why you may have to spend money on wall insulation.

To choose from these two options, you need to be clear about what exactly you want from your house with an attic from a bar.

The technology of building houses from a bar

The process of processing a bar is different high complexity and has a lot of features. Therefore, it is strongly not recommended to carry out construction work independently. It is better to hire professionals in a specialized company. But in order for you to have a more detailed understanding of the technology of building log houses, the features of this type of work will be described below.

Features of wooden construction

Wood is a very capricious material that requires strict adherence to all technological operations.

Bar properties depend on its moisture content, which may vary. Therefore, in the construction of buildings, an amendment is made for possible shrinkage or other deformation. All calculations are based on the properties and parameters of a particular material.

is very important For the construction of wood, it is very important that the master had developed carpenter skills. The fact is that the use of timber implies a large number of all kinds of filings, grooves and the use of other technical nuances. The strength of the building is directly dependent on the quality of the docking stations.

Construction of houses from a bar is usually performed in two stages. First of all, the frame, walls and roof system are assembled, the floor is laid and the roof is covered. The second stage is all the finishing work. There must be at least six months between these procedures, because the tree must "sit down in its place" from which the structure will acquire rigidity.

Important! When improperly processed, all glued bar brands are subject to loss stiffness of joints. It threatens with cracks and cracks in the wall.

Besides all other features, wood has another negative quality - it has different strength and elasticity when the direction of force application to the bar is changed. Therefore, there are special docking methods that help minimize this drawback. For example, when using a profiled bar, in its upper and lower surfaces, with the help of special cutters, grooves and spikes are made that serve as fixers.

Usually the rows of bars joined together in this way are also long pins. This is necessary to prevent deviations of the segments from their position. Such a wall will retain its geometry.

In addition, various adhesives are actively used in wooden construction. They help transform the rows of stacked bars into a monolithic structure. When building a house from edged timber, it is necessary to seal the joints. For this purpose, dried moss was used before, and now fiber flax tow is used. Incidentally, it is believed that thick moss is less susceptible to aging and rotting, so it is still used in wooden construction, although quite rarely.

At least two weeks before the start of construction work, all materials should be treated with antiseptics and fire retardants with organic solvents.

On our website you can familiarize yourself with the most popular projects of houses from double timber, laminated veneer lumber and profiled timber - from construction companies represented at the exhibition “Low-Rise Country”.

How houses are built from timber

The simplicity of the docking and the low cost of the material make the construction of a wooden house accessible and fast, provided that all elements and processes are carefully thought out and planned.

If in general, the construction of a house from a bar with an attic looks like this:

-

Laid foundation

-

Assembling and joining walls and floors

-

Going truss roofs

-

roofing and finishing works

An important feature of the construction of timber is that it does not require any heavy lifting mechanisms. A small house in general can be built by two professionals.

Now about the foundation of a small house from a bar with a mansard. In general, properly assembled wooden houses have a fairly high resistance. Therefore, depending on the soil on the site, you can find a variety of options for fixing the box at home.

Note ! Usually, a freshly assembled structure has a stiffness of only 50% of the calculated one. After shrinkage and swelling this is compensated. Therefore, it is usually left at the joints gaps and gaps, which lay soft sealants. As the wood swells, a hard box is formed.

The first row of bars is called the crown. If it is weak or installed on poorly twisted piles, then there is a danger of subsidence of the walls under its own weight. The best time for laying crowns is a frosty winter. At this time, the tree quickly swells and becomes stiff at the joints.

Usually, pile or pile-foundation foundations are used in wooden construction. Sometimes create tape shallow designs. The wooden crown is prone to rotting and moisture, so the best option for a log house will be a pile-welded construction. And in order to increase the operational period of the timber, you just need to properly equip the airways and ventilation shafts.

The pile-grillage foundation itself is a series of supports immersed in the ground below the level of freezing and connected by strapping from steel or reinforced concrete. On this harness and fit the first row of timber. The peculiarity of this design is that it provides a uniform pressure of the house on the soil and the soil on the foundation.

After the base has been equipped and waterproofed, fits the first row of timber. For its fastening anchor bolts are installed in the foundation tape with a step of 60-70 cm. Then they put a timber on them and hit it with a hammer. At the place of the formed marks, drill holes with a diameter equal to the diameter of the anchors.

When laying the rim, they usually level the level, bringing it to the horizontal. If it was not possible to achieve a flat line, the upper part of the beam is removed by a plane. If this is not done, then the whole structure will go awry. Also, the trimming and trimming procedure is also carried out when laying the following rows in the event that the beams themselves have deviations. Observing the technology, it is especially necessary to thoroughly and carefully handle the places of cuts and gash, as they are most susceptible to all sorts of negative factors.

On our site you can find contacts of construction companies that specialize in building houses from profiled6 glued and double timber. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Lags under the next floor are laid over the crown. The step should be 40-50 cm.

Before construction, the tree is usually sorted. Curves, diseased bars, are rejected. They are most often used for small frames or to create forests. Often in wooden construction, the bars are joined in half-wood, and the joint itself is overlapped by the next row.

In the nodes of the lagging and beams inserts, the dug-ups must be clogged. And the nog must pry at least three rows of the bar. It uses not only metal, but also wooden fasteners, made from the same wood as the walls themselves.

The connection of the bar in the last row is performed in the form of a dovetail gash or a T-shaped gash.

All beams will crash as walls are erected. However, no partitions should not be installed until the box is fully assembled. Even temporary decks and forests should not be more than 1 m in length.

During the construction process, external modules, such as a porch or a veranda, are being erected simultaneously with the walls. It is possible to move on to the flooring only after the installation of all the ceiling beams and the truss system, therefore the next stage of construction is the arrangement of the roof and the attic.

Construction of an attic from a bar

In general, in Russia, almost all houses were built with the expectation that they would have an attic. Therefore, there are a large number of technologies and technical solutions for the creation of a roofing room from a bar.

In general, the choice of attic construction depends on many factors, for example, on the purpose of the room. But regardless of this, the overall construction technology remains unchanged.

Attic is the simplest version of the second floor. However, according to experts, it is more expensive than a full floor due to the fact that the area of its ceiling is much more significantly increased due to the slope.

In any case, construction of the attic begins with the installation of mauerlates. This is the name of the structural element that supports the truss system. In our case, the upper crown of the box will be the masterpiece. It is important that it is firmly and motionless fixed to the wall. There are several options for fasteners. The most important thing is that the power plate is strictly horizontal, and all its sides are in the same plane.

Thick wire or reinforcement can be used as accessories. But it is best to mount the power plate to the anchor bolts, as well as the lower crown.

The video will familiarize you with the installation procedure of the upper crown log house:

It can be interesting! In the article on the following link read about the country house from a turnkey bar - price, quality and comfort in one bottle.

The microclimate in the whole house directly depends on the airflow under the roof. Therefore, in wooden construction, the attic floor is usually assembled on pins. However, this method has a higher complexity of execution. But with such a fixation, you are guaranteed to get maximum fusion in all corners and joints.

Pins are made from hardwood. The element itself must be hammered into the corner of the junction of two bars. It is important for the key to fit into the groove as tightly as possible. Such wedges not only increase the strength of the joints, but also lower the thermal conductivity of the log house. Keys can be of different shapes: rectangular, prismatic, in the form of "dovetail". But other options are possible joints.

In this video, the wizard will tell you about the main ways of fixing the beam, including the keyed connection:

But the bottom row of the wall mansard floor must be docked in half-wood.

Now about the truss system of the attic floor. It is considered that the room is convenient if on a half of its area the height of the ceiling is equal to or exceeds the height of a person. The very height of the ceiling and its shape depends on the type of roof, and, consequently, on the roof system.

You can choose the type of roofing based on the size of the building, but the dual-slope scheme will be the most advantageous in terms of savings. Also be guided by the estimated snow load in your area. For rafter legs usually use a board with a section of 15х40 mm. Legs are installed in increments of approximately 1 m. The specific value of the magnitude depends on the terrain. In advance in the roof should be left window openings. If the angle of inclination of the roof is less than 30 0 , then windows should not be installed in the roof.

When creating the attic floor, the batten and counter lattice should be as strong as possible. It is also recommended to lay two layers of thermal insulation.

The attic rafter system usually has an increased weight. Therefore, it is worth while creating the roofing room to pay attention to whether the foundation of the house is designed for such a load. In order for the microclimate in the house to suit the owners, it is necessary not only to carry out all the joints qualitatively and carefully, but also to choose the right wood. Best for loft fit larch. The most rational for insulation use fibreboard. Additionally, mineral wool is laid. It is recommended to use shingles or slate as roofing. Natural materials should not be chosen because they have more weight.

It might be interesting! In the article on the following link read about the technological features of building houses from a bar.

Floor from a bar

After the attic is ready, you can start laying the floor. Since we consider a tree house, the floor will be of the same material.

The floor construction is already in the planning stage. This will avoid violating various building codes.

There are three main types of floors.Underfloor heating is a fairly popular innovation. Heating from zero level is very profitable, both economically and energetically. The fact is that when warm air rises from the bottom, it provides the most uniform heating of the room, and the most optimal temperature is set at 1.5 m.

Heated floor is the most suitable option for wooden houses. Insulation is laid in the intervals between the lags. It is best to use mineral wool. It is very important that the underground space of such a design is ventilated as efficiently as possible.

Cold floor is used only in non-residential or technical premises. The advantage is that it can be installed without a subfloor. The finishing coating can be any material.

Before you start building, you need to think about the system by which the floor will be arranged. If the logs will stand directly in the foundation strip, then at the initial stage of construction you will need to leave cuts under them, as well as to equip ventilation shafts.

For lags, bars are most often used. The greater the design load on the floor, the smaller should be the step between the supports. Also chosen such a width of the bar to fit in a niche plate insulation. Usually, in order to maintain the distance from a piece of slats, they make a template with which they check the uniformity of the step. Lags in no case should not be based on the ground. Install them on the boards. Floor supports are attached to the frame with metal perforated corners.

This video tells how the lags fit:

When erecting a heated floor, a draft floor is an essential element. He must keep insulation and waterproofing. To create this element, you can use b \ y boards.

It might be interesting! In the article next read the link about what you should pay attention when ordering a house from a bar "turnkey".

Next you need to create a draft floor. It will prevent the building from being blown from below and will provide support for the laying of thermal insulation materials.

Often in the underground space rodents settle, which begin to spoil the insulation. Because of this, an unpleasant smell can appear in the house. To prevent this, right on the logs you need to lay a layer of metal mesh with a cell of 20x20 mm.

When installing the draft floor boards, they are usually sawn with a circular saw or a hacksaw and fixed with self-tapping screws. Further over them the bar in the form of a lattice is sewn. Glass wool is laid in such a frame. From above, everything is covered with a finishing coating, as which high-quality natural wood is often used. Any other material can worsen the interior of a wooden house. The best option for floorboards would be larch. From above it is possible to put a varnish coat.

Several options for planning a house from a bar with an attic

To housing It was the most convenient and comfortable, you need to think carefully about its internal structure. Therefore, below we consider the layout of houses from a bar with an attic.

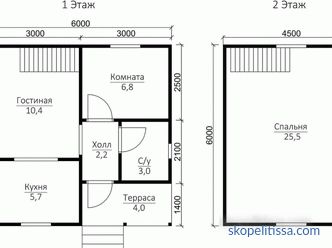

The layout of the house is 6x6 with an attic

With such dimensions you can create an economical and comfortable home. Relatively few materials will be used for its construction, and the heating of such a house will be inexpensive. With proper planning on the area of 36 square meters. m. practical building will be located.

This option provides for a free room. Therefore, it is suitable for almost any person. On an area of 6.8 square meters. m can accommodate an office, a small steam room or children's room. The bathroom is inside the room, so you can live all year round in such a residence. There is a terrace on which a rocking chair or a mini-sofa can be well located. In the warm season, you can read or just relax in the fresh air.

Any housewife will appreciate the rather spacious and impassable kitchen. On an area of 5.7 square meters. m will fit gas stove, shelves, sink and dining table. All attic is invited to leave under the bedroom. For the most efficient use of space under the stairs, a wardrobe in the form of a triangular prism can be located. The advantage is the presence of a living room where you can receive visitors or spend your free time.

This layout is well suited for a country house from a bar with an attic.

Here is another successful project of a 6x6 wooden house with an attic:

It might be interesting! In the article next link read about the comparison of timber and laminated veneer lumber.

House project 7x8 with a balcony

This option is already bigger than the previous one. By area with a mansard, it is commensurate with the three-room apartment. In such a house will easily fit a family of four.

The terrace is a universal place to relax. Also, it will give a more attractive and status view of the dwelling. The bathroom is located inside, which can be called the advantage of planning. The kitchen has a fairly large area, so it can play the role of a dining room. However, its disadvantage is that it is communicating and not divided from the living room. If desired, the door can be put on the doorway, so that smells and sounds do not reach the place of rest.

Since the living room has a large area, it will successfully accommodate bookcases, shelves for hobbies, and even a large number of indoor plants. This layout is well suited for those who like to host guests, besides a free bedroom gives them the opportunity to stay with you for the night. A large hall on the attic floor can be used, for example, as a photo gallery.

A balcony from a bar is a highlight of this plan. He is able to play the role of both the observation platform and the working cabinet. Another version of its use is growing light-loving plants on it.

Thus, from a bar you can build a 7x8 house with an attic, which will be spacious and practical housing.

Planning of a house with a loft 9x8

This is already a fairly spacious option that can fit a large family.

This layout provides for two bathrooms in the house, which is considered very convenient. Also of the features worth noting the presence of the boiler room. The fact is that, with such dimensions, the house will have to be heavily heated, and all boilers take up space. Therefore, they are invited to clean in a special room.

In the large hallway you can easily place all the outerwear and shoes. The kitchen-dining room is 20 square meters. m will accommodate your family and guests. At the same time there will be a place for cooking. Attic floor consists of four living rooms. In place of some you can equip children. Wooden balcony will be a real decoration of the home.

It might be interesting! In The article on the following link read about sand furniture.

Conclusion

A bar house is a good and environmentally friendly solution. It suits you if you value your health and the health of your loved ones. In addition, for a large part of the territory of Russia wooden dwelling is traditional. Attic is also able to increase its usable area and improve appearance. Now the construction of houses from the bar with might and main is gaining momentum. All this can be called a weighty reason to get a spacious and beautiful home from a bar with a mansard.