Proper, proper installation of floors - a guarantee of reliable, long-term service life of buildings. For buildings made of blocks (aerated concrete), additional support is needed - reinforcement. Armopoyas in the house of aerated concrete - this is a special additional structure, mandatory when installing beams, roofs. The manufacture of reinforced belts for houses made of cellular concrete, the installation of floor slabs is regulated by the SNiP. Here are the brands and characteristics of the beams, the necessary parameters of the bearing on the wall, from what and how is done. Compliance with these standards is directly related to the structural stability of building structures.

For what is needed an arm-belt

Aerated material structure will not to withstand high loads (shrinkage of the building, sediment under it, daily temperature drops, seasonal changes). As a result, the blocks crack, collapse. To avoid various kinds of deformations, monolithic reinforced concrete devices are installed. Reinforced belt takes these loads on themselves, distributes them evenly, ensuring the reliability of the structure, binds the walls into one.

It is also needed to distribute the vertical load. Giving the structure rigidity, it does not give rise to the movement of the overlap (aerated concrete blocks expand with the movement of moisture, steam). For this, he also received the naming - unloading, seismic belt. Another of the missions of the armored belts is to protect the edges of the upper blocks from destruction (installation of floor decks). Remove the point load beam wooden frames, with the construction of the roof. Considering these qualities, armopoyas is obligatory for beams, slabs of the second (subsequent, roof) floor in the house of aerated concrete blocks.

When building one-story buildings, the question often arises whether one-story house of aerated concrete. This element is simply necessary if:

-

are installed support beams (mauerlat), which are attached to the rafters of the roof, this is especially true for projects of single-storey houses with an attic;

-

The foundation is made on an unstable ground to bind the entire structure into one (carrier) system.

A prerequisite for houses made of aerated concrete blocks is the complete looping of the belt. The contour of the structure must be without breaks. Rejecting the use of armored belt, the appearance of cracks is inevitable. Even in spite of light hardwood floors and reinforcement of masonry from aerated concrete blocks.

Interfloor reinforced belt

This type of construction is performed for slabs or beams. The main purpose of floors, is the perception and transfer of the load of its own weight, interior, people on the walls, the division of the internal space of buildings on the floors, overlapping spans. It is a supporting structure resting on external and internal walls along the entire perimeter.

The base surface of the load-bearing walls, which perceives the entire mass of a living structure, serves as the basis for pouring the arm-belt. General requirements:

-

installation is performed on the entire perimeter of the future building, taking into account the internal walls;

-

for external bearing walls, blocks with a density not lower than D-500;

-

height, made according to the height of aerated concrete, or less than (200-400 mm) allowed;

-

belt width - 500 mm (reduction by 100-150 mm is possible);

-

it is recommended to make the armored square (in cross section), this form is more sturdy, keeps mechanical loads well;

-

the reinforcement cage rests on stands (brick, block pieces, plastic retainers) height 3 cm, so as not to touch the walls, thus creating a so-called protective concrete layer;

-

, concrete not below grade B-15 is used for casting.

On our site you can find contacts of construction companies that offer a foundation repair service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Arm-belt for aerated concrete under the floor beams, poured into pre-prepared formwork. Such a frame is made of:

-

Plastic.

-

Aluminum.

-

Iron.

-

Plywood.

-

Tree.

-

Aerated concrete blocks.

Wood formwork

This type of formwork is used most often. This is the cheapest and most popular option.Installing a double-sided removable wooden frame (shits of wood), it is fixed with screws on both sides of the wall (to the blocks of aerated concrete). The upper part is tightened with wooden lintels (step 800-1000mm). This is necessary so that, when pouring concrete, it does not push the structure apart.

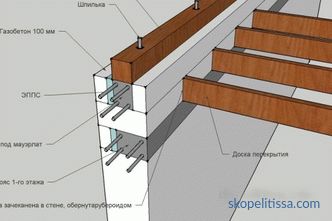

Reinforcement frame (reinforcement diameter 8-14 mm), made in the form of a "ladder" (connecting jumpers with a step of 5-7cm), fits into the prepared space. The rods fit together, using a knitting wire (every half meter), forming a square shape. It is not recommended to use welding, due to rusting of the welds in the concrete. For beam ceilings (with a not high load), the frame of two rods is enough, with a monolith height of 30 cm. For overlapping plates, armor belt with increased reliability is used (4 rods and a monolith - 40 cm).

After removing the formwork, the outer wall is insulated along with the armor belt. If the exterior walls are only plastered during the finishing, then to remove the "cold bridge", the formwork moves deep into the wall. And in the resulting niche, then a heater is installed.

One-sided formwork can be used. In this case, the outdoor function is performed by aerated concrete blocks (10 cm thick). They are laid on the bottom row with glue. From the inside there is a wooden frame. After that, insulation (5 cm) and fittings are laid. Top, also bridged.

How to make wood formwork for arm-belt:

It might be interesting! In the article on the following link read about interior decoration of the house of aerated concrete.

Belt using blocks

Making such formwork requires additional finishing blocks or ready-made U-shaped aerated concrete products. In this case, on the glue (on top of the previous row), internal (5 cm thick) and external (10 cm) or U-blocks (with 5 and 10 cm walls) are installed. In the inner space, fit fittings and insulation (to the outer wall). After, there is a pouring of concrete. For openings (doors, windows), at the top of the previous row of masonry, wooden lintels are installed. They are fixed with vertical props.

This formwork option is relatively quick and easy to install. But it is not very popular because of the need to purchase additional material and, as a result, increase the cost of construction.

The belt under the power plate

This armopoyas is installed below the attic, both for single-storey and for two or more storey buildings. It is necessary for the installation of fasteners under the power plate, and takes the main load from the roof system (vertical, aimed at breaking the force) and the load from snow, wind. Installed mounts for timber just in aerated concrete, will not withstand these loads. They will be loosened (due to the low strength of the blocks) and the power plate will move from its place, which will inevitably lead to negative consequences. He also plays the role of additional strengthening of the walls, preventing them from cracking.

Such a belt can be made smaller in size due to the thickness (having correctly calculated the load) and use two reinforcing rods for the framework. A distinctive feature of such an armopoyas are vertical studs with nuts. They are installed together with the reinforcement cage, before pouring concrete. It is on these mounts and will be installed mauerlat, fixed with nuts on top. This is a bedrock base for a roof truss system.

In the same way, you can make armor in a house of aerated concrete and under wooden floors. Pre-prepared fasteners for wooden structures, will avoid the subsequent drilling of concrete for the installation of anchors.

It may be interesting! In the article on the following link read about the floorings in the house of aerated concrete.

Filling of concrete

For filling the belt, after all the preparatory work is done, ready-made concrete (M200) is used or made on site in a ratio of 3-5-1 from:

-

sand;

-

rubble;

-

cement (M400).

Filling is carried out not in parts, but completely around the perimeter. In case of impossibility of such a process, the necessary jumpers are made in advance. Before pouring the next batch of concrete, temporary lintels are removed, the joints are moistened with water and filled with concrete. Compaction of the solution is made with an iron pin, removing air bubbles from it. In the process of solidification (about 5 days), the concrete is poured with water to increase strength.

Preparation of mortar for pouring armored belt:

It can be interesting! In the article on the following link read about the dimensions of aerated concrete blocks.

Conclusion

The reinforced concrete monolithic belt, carried out in accordance with all the necessary parameters and rules, will give the house of aerated concrete blocks the necessary strength and durability. Protects the walls from premature cracks, will make a reliable roof.