Geomaterials, which relatively recently appeared on the construction market, gradually conquered its vastness. After all, with their help, several construction processes are simplified many times with the low price of the products themselves, and the quality of the final result increases. In this article we will talk about geogrids for tracks in the country: what they are, what they are made of, the range and technology of use.

What is a geogrid

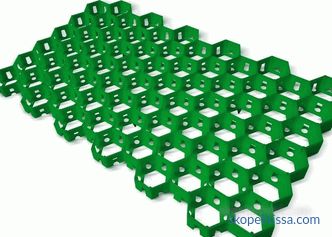

In the name of the material there is a term - grid . But it is necessary to understand that this design is three-dimensional, that is, volumetric. In this case, the material is assembled from tapes connected by welding or soldering. The structure of the geogrid because of this turns out to be cellular, in which the cells are arranged in a checkerboard pattern. In this way, the rigidity of the structure and the strength of the coating, in which the geogrid is used, are achieved.

The purpose of this bulky cellular material is to keep the soil from being subjected to "heavy spreading". Therefore, this material is mainly used in road construction, laying under the floor of the roadway. And also to strengthen the slopes and slopes.

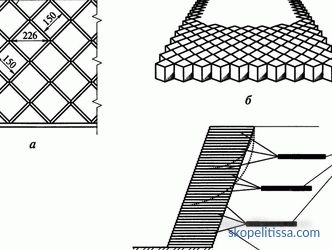

In road construction, before the appearance of geogrids, metal nets were used, woven in a chain-link type. As well as concrete cellular products, which are stacked next to each other. In the photo below, this kind of track reinforcement is shown.

It was all expensive, moreover, the metal quickly broke down under the influence of natural loads, because that twitched in the ground corrosion. Concrete served for a long time, but there are concrete products are very expensive. Yes, and work with them more difficult. And when geomaterials appeared on the market, they quickly displaced both metal products and concrete.

Material for geogrids

Today, manufacturers offer several varieties of geogrids for garden paths made from different materials.

-

Polymeric volumetric . Basically they are made of polystyrene. In fact, these are tapes that are fastened together by welding or by ultrasonic soldering. On the market, this type is represented by two variations: solid or perforated. The first is used if the filler is a fine-grained material, for example, sand. The second is used if the filler has a coarse-grained structure, for example, crushed stone or gravel. The height of the tapes used varies from 50 to 300 mm, this parameter creates the volume of the structure.

-

Polymeric flat . This is a roll-type material, which is not a grid, but a grid, although it belongs to the category of "geogrid". Its height is the thickness of the polymer bar from which the mesh is made. Manufacturers offer two types of mesh: single or biaxial. The first works only on stretching in one direction - longitudinal. Therefore, in its construction there are rectangular cells, that is, elongated along the roll. This grid is mainly used to strengthen the slopes. The second is a lattice with square cells that can withstand loads in the transverse direction and in the longitudinal one. Hence its high versatility. Polymer mesh made of polyester or polypropylene.

-

From geotextile canvas . That is, for the manufacture of geogrids needles of needle-punched or woven geotextiles. In this case, use a high density material. This is the cheapest version, but not with the highest performance. And although such a geogrid is well able to withstand tensile stress, it has a small compressive strength, especially transverse. Therefore, this type is more often used as a demarcation layer between different layers of stacked building materials.

-

Plastic . They are made mainly of polyethylene and low and high pressure. They are mainly used in summer cottages when it is necessary to build paths, platforms or parking places. Firstly, it is rigid structures with certain dimensions by area. Secondly, the panel assembly simplifies the installation process. Thirdly, the rectangular shape easily forms the areas of pads and tracks, without significant changes to the lattice itself.

On our site you can find contacts of construction companies that offer the service drainage and drainage systems. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Rules for using the geogrid

Since this material is represented by models of different versions, the method of its installation will differ. First of all, they make the markings for the tracks, and then remove the sod with the root system. Next level the base and rammed.

If a polymeric product assembled from tapes is used as a geogrid, then it will be necessary to lay geotextiles under it. The remaining operations are carried out in the following order:

-

At the edge of the walkway, L-shaped pins of the form are driven into the ground to a small depth (not completely). They are usually made of thick wire or thin steel reinforcement. The distance between the pins determines the cell sizes of the selected grid material. For example, if the cell size is 210x210 mm, then the step of installing the pins should be 210 mm, if the cell is 400x400 in size, then the pins, respectively, should be driven into the ground every 400 mm.

Our site contains the most popular house designs from manufacturers. Here you can find contacts of construction companies, in filters set the parameters of the house, technology, cost, finishing materials, as well as other characteristics and construction processes of interest. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Lay out the geogrid so that the pegs driven into the ground fall into the middle of the ribbon forming the cells. Then pins hammer in until it stops.

-

Stretch the geogrid to the opposite edge of the track and immediately attach it to the ground with pins, hammering in order into each cell. Since the garden paths have a small width, this number of fasteners will be enough. If a site is being constructed or parking for cars, then the geogrid will have to be nailed not only at the edges, but also every 0.5-1.0 m. At the same time, fasteners must be placed in a staggered manner.

-

If one roll is missing, then the second is laid next to . The edges of the two elements are interconnected by knitting wire or plastic clamps.

When the trellis base under the track is ready, you can fill it. If it is a concrete mortar or crushed stone, then they fill the cells to the upper edges. If sand or soil is put in, the backfill is made in excess of 25-50 mm filling, because any bulk material shrinks over time.

The video shows how to lay a voluminous geogrid and fill it with crushed stone screenings to form an entrance to the dacha:

Experts pay attention to the fact that quite often the masters make a big mistake by dropping the filler from great height. It damages the slatted material. The optimal discharge height is within 0.6-1.0 m. If the cells are small, then 60 cm is an ideal parameter. If the lattice cells are large, then it can be increased to a maximum.

It is easiest to stack geogrids made of hard plastic. These are panels of a certain size, which are laid against each other and fastened with the same pins. Nothing to stretch and customize. If the extreme row of grids in the boundaries of the garden path does not fit, then the panels can be easily cut to the required size with a hacksaw or a grinder with a cutting disc.

in rows It can be interesting! In the article next read the link how and from what to make the track in the country: 9 popular materials, + examples of designs.

The price of the proposed products

Today it is not a problem to buy a geogrid for tracks in the country. They are present on the shelves of hardware stores and markets. They are sold today even in online stores. It is clear that prices vary greatly in the material from which they are made, in size (height and width of the cells), and in the regions.

Let's mark some geogrid prices for garden paths.

-

lattice height 50 mm , cell sizes - 210x210 mm, price: 70 rubles for 1 m² of canvas;

-

height 70 mm , cell size 320x320, price - 50 rubles. / m²;

-

height 100 , cell parameters 160x160 mm, cost 180 rubles per square meter;

-

height 200 , cells 210x210, the price of the product is 255 rubles. / m²

That is, it turns out that the smaller the cell size, which means the denser the material itself, plus the greater the height of the lattice, the higher the price of the building material. But since the garden paths in the country practically do not run into serious loads, it is recommended to purchase not the most expensive option for their device. And this can be a 50 mm high geogrid with a cell size of 210x210 mm.If you need to strengthen the site for parking, it is better to use a material with dimensions: height 70-100 mm, the parameters of the cells from 160 to 400 mm.

It might be interesting! In the article on read the following link about the consequences of the work of the gray brigades: what to look for when choosing builders.

About cells and material

So, today geogrids are produced with certain parameters. This is a height in the range of 5–20 cm, the dimensions of the cells are from 16x16 to 40x40 cm. The ribbons themselves, from which the gratings are assembled, can be perforated, solid or combined. But in any case, the surface of the ribbons is a textured plane. We add that the perforated surface simply improves the soil drainage, it has no other purpose.

As for the tape texture, its purpose is to increase the fastening of the geogrid with filler. And this, in turn, increases the strength of the material itself due to the friction force that occurs between the grid and the filler, when some load presses on the first. In this case, the friction force does not decrease with decreasing filler grain.

It should be noted that experts recommend using perforated geogrids even for building garden paths. Because they have rather serious strength characteristics, due to the fact that:

-

a frictional interaction appears between the walls of the grid and the filler grains;

-

due to the filling with the granules the walls of the ribbons;

-

the plant roots without difficulty pass through holes , thereby fastening the grid;

-

under the action of heavy concrete tapes bend , creating complex shapes, thereby forming complex modular constructions whose strength characteristics are higher.

We add that the perforated version is cheaper than the solid one because it takes less raw material. As mentioned above, water permeates through the perforated tape. That is, a transverse drainage system is organized.

The video shows how to make a three-dimensional perforated type lattice:

It may be interesting! In the article on the following link read how a prototype floating island with a live tree launched on the Copenhagen harbor.

Conclusion

So, we told you about geogrids. It should be noted that today builders are actively using them, especially in activities related to the strengthening of slopes. And even in the suburban areas this material has found its application. Do not go away from penny expenses. It is better to buy a geogrid and install it under the garden paths, which then will meet all the requirements of modern construction.