Sandwich panels and sip panels (Structural Insulated Panel) are new generation materials and are gradually gaining popularity in commercial and private construction. Blocks made on the "puff pie" principle are used for the construction of low-rise structures for various purposes. In order to save money (both money and time), the owners of the dacha plots are increasingly choosing cabins and hoppers from the vulture panels. The construction and arrangement of such structures requires a minimum of time - from several days to a month (depending on the complexity of the project). Due to the simplicity of the assembly, the box of a small structure consisting of a frame and skin is built in one day.

One of the main advantages of this material is the absence of restrictions in seasonal work: construction possible in the winter. Also, there are no complaints about the strength and thermal insulation of buildings from CIP. On both sides, the “layer cake” is protected by profiled metal sheets with a glossy / matte finish or OSB / OSB (oriented strand board), while for the internal filling polystyrene foam, polyurethane foam, and sometimes mineral wool are used.

Features of sheds from sandwich panels

The sip-technology is unique in its kind:

-

Convenience of working with sandwich panels consist in the simultaneous construction and wall insulation .

-

Due to the light weight of the load-bearing walls, the construction of a capital foundation is not required, which significantly reduces time and money.

-

The bead of the panel keeps the fasteners well together - it is easy to work with them during exterior and interior decorating.

-

Plates with galvanized or polymeric coating are not exposed to corrosive effects and decay.

Small change houses for temporary and permanent residence are assembled from multi-layer slabs. In the pre-fabricated buildings can be placed: a dining room, shower, locker room, storage rooms, pro-shop, mobile office or first-aid post, checkpoint.

Note! The uniqueness of collapsible structures lies in convenient transportation and quick installation in a new place.

Options for SIP-panels for the construction of change houses

For the construction of cabins for different purposes apply the appropriate panel. On the market are multi-layered plates of several brands, which differ in thickness and format. The internal filler is PSB-S-25F (self-snuffing facade polystyrene foam) 10–20 cm thick. The outer lining consists of an environmentally friendly Egger Eurostrand OSB-3 plate with a thickness of 9–12 mm. The standard dimensions of the panels are presented in a wide range - 6250x2240, 2500x1240, 2500x1740, 2500x2240, 1250x1240, 1250x1740 mm. If necessary, the elements are cut out according to individual parameters.

On our website you can familiarize yourself with the most popular small-form projects of CIP panels from construction companies represented at the Low-Rise Country home exhibition.

Designing a shed from a vulture panel

A wide variety of projects are being developed for structures assembled using the vulture technology, and there are no restrictions in shape or size. In addition to standard sketches, you can make changes as the external and internal decoration, and change options for laying communication networks.

When developing a project, the following are taken into account:

-

Area common and separate rooms. The parameters depend on the purpose of the shed or the number of residents.

-

Type of construction - a changeout from a vulture panels can be capital or collapsible (if necessary, move from one object to another).

-

Type of communication networks (water supply, sewerage).

-

The type of roof is flat, single or dual slope.

-

Structural features - the presence of a canopy, a porch, internal partitions and their location.

-

Number of doors (entrance, interior), windows and their location.

The most common projects are:

-

Summer kitchen with a spacious porch or roof, flat or gable roof, a minimum number of windows, but not less than 2 with one or different sides.

-

A change house as a country house . The single-story building has a standard rectangular or L-shaped form with one or two windows and a porch (shed). Two-story construction with an attic and stairs to the second floor.

-

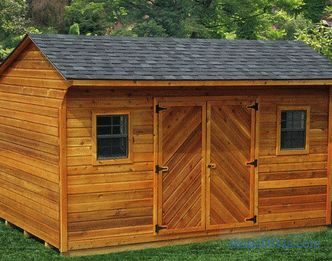

Country barn of the vulture panels.A standard rectangular shape with a flat roof and one window is under construction. A shed of sandwich panels is quite warm, and you can worry about inventory and other things in the winter.

-

Sanitary and household trailers . Such buildings must have several separate rooms, including a washroom, a bathroom, a bath, and a dressing room.

Cabins from sip-panels are suitable for living all year round. Bearing walls consisting of multilayered slabs with filler, have excellent thermal insulation characteristics, so this building does not need additional insulation.

The choice of materials (wall, floor and roofing) depends on the operating design characteristics.

The developer can independently develop a sketch version of a pre-fabricated structure. But if you need a ready-made bunk from a vulture panel 3x6, you can buy it from manufacturing companies, on the site of which numerous typical projects are presented. The cost varies depending on the complexity and design parameters.

On our website you can find contacts of construction companies that offer the service of building small architectural forms. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Stages of assembly of change houses from a vulture panels

Construction of a change house is carried out in the following order :

-

Prepared site under construction.

-

Equipping the foundation .

-

Mounted frame .

-

The wall elements are installed.

-

The roof and floor are equipped.

-

Windows and doors are mounted.

-

finishing works (external and internal) are carried out.

For a change house from SIP panels, it makes no sense to make an expensive monolithic foundation. Optimal options: shallow-tape, concrete blocks, pile or columnar. On the ready basis the framework is mounted. Wall material is cut according to design drawings. On the elements in which the windows and doors will be installed, marks are put - before installation, openings are cut into them with a chain saw. The installation of the plates themselves start from one of the corners of the future shed.

How installation of CIP panels is carried out - the experience of foreign builders in the video:

The power unit from sandwich panels is assembled similarly to panel technology. Various fasteners are used in the assembly of the structure:

-

timber;

-

self-tapping screws;

-

mounting foam .

CIP plates are mounted on a wooden or metal frame, joining with each other using the thorn-groove method. Fastening is carried out with screws, which are screwed with an offset (in a checkerboard pattern) in 15 cm steps. There is also a frameless technology, when the connecting elements are splines from OSB-3, cut from multilayer plates of smaller thickness. Panel walls act as bearing elements and withstand load well.

Note! The technology for installing window and door structures is standard - special plates and foam are used as fasteners.

Lower and upper harness. Roofing

After the walls are installed, the bottom trim is assembled and the sub floor is created. Bottom trim is laid on the foundation with waterproofing (bitumen mastic or roofing felt) and secured with anchors. Corner joints of the beam are performed by the "paw" method. As a subfloor, multilayered sandwich plates or edged boards 5x10 cm are used, which are laid directly on the logs. Flooring can be any, but linoleum and cork floors are best suited.

The bars for the top trim are placed in the end part of the SIP panels along around the perimeter and connected with screws. Further works on the arrangement of the roof are performed in accordance with the chosen construction:

-

The truss trusses are installed.

-

Fitted roofing finish for flat roof .

In the roof of a single-pitch SIP-panel material stacked on the mauerlat, and rests on a ridge beam that combines two gables. The elements are fastened with screws and joined in the same way as the plates on the walls. CIP panels for the roof are impregnated with antiseptic and water-repellent bitumen mastic, so before installing them do not need additional vapor barrier. The roof of the plates is covered with corrugated roofing, bituminous tiles. Roof slope depends on what material is used.

It might be interesting! In the article on the following link read about the draft of the shed.

Interior and exterior wall decoration. Warming

For interior walls are used:

-

Gypsum plasterboards;

-

Wallpaper;

-

Tile;

-

Paint and other finishing materials.

When using thin CIP panels or in structures intended for permanent residence, the walls can be additionally insulated with mineral wool, which is attached to the frame of the crate. Vapor barrier material is located between the insulating layer outer lining.

How the insulation of a building is made of CIP panels in the following video:

Material that is resistant to negative atmospheric influences is necessarily used for exterior decoration. For exterior finishes the following materials are used:

-

Gypsum-fiber moisture-resistant sheets - GFL (frameless lining with self-tapping screws);

-

Paint for exterior works;

-

Cement based plaster.

-

Any kind of siding (acrylic, vinyl, metal).

Note! For all change houses of the vulture panels, the price is formed on the basis of several parameters: the area of construction, the amount and type of materials, the complexity of the project.

It might be interesting! In the article on the following link, read about country cabins.

Conclusion

Sandwich panels and sip panels are an alternative to traditional materials. Thanks to such innovative technologies, construction time is reduced, and you can also buy a ready-made barn of vulture panels and assemble it on the site. The effectiveness of cabins from sandwich panels has already been confirmed by their repeated use.