In various places, fences get the most colorful names. They are called front gardens, fences, fence, fence, or just a wall. Fences are made of the most common natural materials characteristic of a given area or artificial, among which fences of corrugated flooring with brick pillars confidently occupy their niche. They look organic on any country site, allow you to create a solid fence, inaccessible to animals and humans, plus the combined brick and corrugated fence perfectly resists any weather phenomena.

Advantages of brick and corrugated fence

Decking allows you to create solid fences that protect the area from prying eyes. The brick helps to strengthen the structure and additionally performs a decorating function. In addition, a brick and corrugated fence has many advantages :

-

durability of the structure;

-

the ability to create organic fences even in difficult multi-level areas ;

-

ease care ;

-

excellent resistance to changes in air temperature;

-

beautiful appearance ;

-

lightness replacement of individual elements during deformation.

Choice of construction and materials

Like any other construction, the construction of a solid and stable fence made of corrugated flooring with brick pillars in a suburban area begins with a detailed plan, calculating the necessary materials and costs. The plan-project includes the design features of the fence, its exact location on the ground and the materials used.

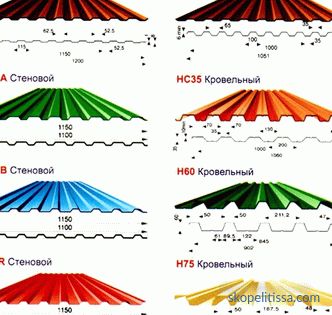

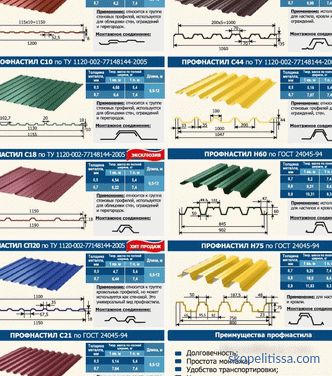

When building a metal fence, are used:

-

galvanized profiled;

-

profiled with single-sided polymer coating;

-

with double-sided coating.

is adhered to when building heavy brick fences made of corrugated flooring generally accepted standards :

-

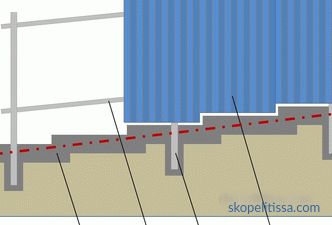

For large elevation differences in the territory of the site, step design is used.

-

When installing supports and the foundation strictly maintain horizontal and vertical levels.

-

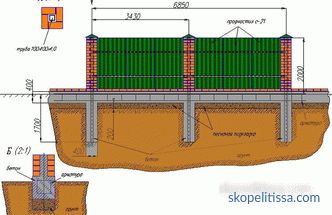

The distance between the columns depends on the height of the fence and is about 3 meters. The higher the height of the fence, the more often set up supporting pillars.

-

For the formation of corner pillars and pillars under the gates, it is better to use thicker and stronger materials.

-

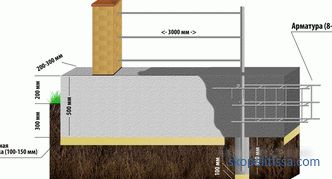

In the construction of corrugated fences with brick pillars, most often design a combined foundation installed below the ground freezing point. It provides immobility, structural strength and a long period of operation of the fence.

-

Correctly choose technical parameters profiled sheeting taking into account the terrain features, desired height and width of the spans using a specialized load table.

On our site you can find contacts of construction companies that offer fences and fences construction service. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Decking for the fence choose a thickness of not less than 0.6 mm. For areas with strong winds should prefer thicker materials. The depth of the wave is not more than 21 mm. Most often at construction of fences from a professional flooring with brick columns use a professional flooring of the C8-HC35 brands with a polymeric or galvanized covering.

-

The number of transverse metal lag of the profiled pipe depends on the height of the structure. For fences up to 2 meters will be enough to install two lag.

-

Installation of profiled sheeting is performed using steel rivets or galvanized self-tapping screws.

-

To prevent corrosion of the material, the welding points are covered with protective anti-corrosion agents .

We prepare the project of the foundation

When building a fence made of corrugated flooring with brick columns, the foundation is an essential element. It provides stability, reliability and prevents premature deformation of the structure.

The difference in the cost of a particular foundation can be quite tangible, so before the beginning of construction is to make a full calculation of all types of foundation and choose the most suitable option, taking into account the features of the terrain and the ground. A brick fence with a corrugated flooring is a rather heavy construction, therefore, in order to avoid difficult repairs in the future, when choosing a foundation, it is necessary to take into account the depth of soil freezing.

For fences from a profiled sheet with brick pillars, strip, column and combined foundations are most often used.

Building a fence made of corrugated flooring with brick columns

Installing a strong fence made of corrugated flooring is not the easiest, therefore, if you lack experience, you should trust the construction to professionals. This will create a beautiful, durable fencing of the territory and avoid additional costs for repair work in the first years of operation.

It can be interesting! In the article on the following link read about fence of boards.

The construction of the fence involves the formation of brick pillars and the reliable fastening of the profiled sheet. In this case, the following technological work steps are performed:

-

The marking of the territory consists of installing restrictive pegs at the same distance around the perimeter of the land plot. Between them they pull a strong cord or rope, denoting the outer borders of the fence.

-

To calculate the number of supports , it is necessary to divide the length of the fence by the width of one span and add support columns required for the decoration of the gate and the gate. The size of the supporting pillars is chosen taking into account their deepening into the ground for a third of the entire length. To install the supporting pillars form pits below the ground freezing point. This will prevent deformation of the foundation and structural elements of the fence as a result of spring snow melting. On rocky soil, the depth of freezing can be ignored. At the bottom of the pits form a sand cushion with a height of 10 cm.

-

A trench for the strip foundation is dug between the supporting pillars . The standard width of the foundation is about 30 cm, the height above the ground is 15 cm. Depending on the geodesy of the area and the characteristics of the soil, these indicators are adjusted in one direction or another.

-

At the bottom of the trench, form a dense sand pillow from a mixture of sand and gravel about 10 cm thick, compacting it carefully.

-

Formwork is assembled from cut boards or OSB boards. The frame for the formwork is made of a transverse beam.

-

The reinforcing frame is assembled from metal rods with a section of about 10 mm. Vertical racks set at a distance of 40 cm from each other and fastened with transverse rods using soft wire.

-

The installation of support columns is performed with regard to vertical levels. Filling is made with concrete solution using Portland cement of grade not lower than M400.

-

For the preparation of concrete solution , crushed stone, cement and sand in the proportions 5: 1: 3 are required. If the length of the fence is not very large, then you can get a quality solution of a uniform consistency, providing the necessary structural strength, using a concrete mixer. If the fence is planned to be long, then it is easier to order ready concrete at the factory.

-

After the entire foundation has been poured, is covered with film and periodically moistened with water. In this form, the foundation for the fence of corrugated flooring is up to complete drying. After that, you can proceed to lining the foundation with brick or stone.

-

For formation brick columns use high-quality water-repellent brick. A protective cap made of cement or metal is placed on top of each support column.

Gate for fence made of corrugated

Since profiled sheet is a versatile material, it can be equally used for both fence and gate assembly, which is most often make swing or retractable.

Swing gates

The most common gates for corrugated fences are swing structures. The design of the swing gates involves hanging the canvas on the supporting pillars with the help of loops. The optimal width of swing gates is 4.5 - 5 meters. The width of the sash is best calculated on the basis of the width of the sheeting. The maximum height of the swing gate is 2.5 meters.

To ensure the normal functioning of the gate, it is necessary to take into account climatic features and provide for a gap under the gate up to 30 cm. To decorate the gap and prevent small animals and poultry from entering the territory of the suburban area, use a removable bar. However, in winter, its use is better to refuse.

Decorative forging installed on the corrugated door will allow you to decorate the structure and increase the height of the gate if necessary.

Swing gates involve the use of one of the designs:

-

Gates with one flap are excellent for forming small receptions. The large size of the sash significantly increases the load on the hinges and often leads to a distortion of the structure.

-

Gate with two wings are more resistant to strong winds. However, the cost of a double gate is slightly higher due to the added cost of hinges, fasteners and frame elements.

It can be interesting! In the article on the following link read about beautiful fences for private houses.

Retractable gates

Often, during the construction of corrugated fences in country areas, automatic retractable gates are installed. Automatic gates are created on an individual project or sold as a complete set, which you just need to assemble into a single structure. It is better to entrust the installation to professionals, especially since for some sets this is a mandatory condition for issuing a guarantee.

How automatic sliding gates are assembled, see the following video:

Wicket for corrugated doors

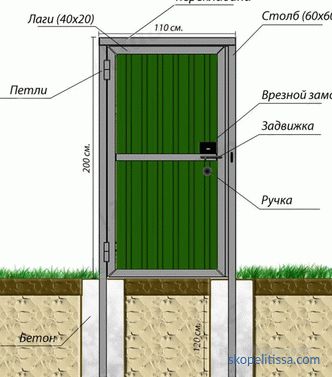

The optimal width of the wicket for the gate of corrugated board is 1-1.2 meters, the height depends on the project of the metal fence and personal preferences. To install the gate, you will need :

-

decking;

-

steel section with section 20x20 for making the frame;

-

canopies;

-

locking devices.

Installation of the entrance gate for the gate is carried out, adhering to the following work steps :

-

Make a durable frame using shaped pipes.

-

Fixing canopies to the frame and supporting posts.

-

Set locks and locks .

-

Suspend frame to support posts.

-

All welds are treated with protective anti-corrosion agents.

-

Fixed decking on the frame.

-

Check the free operation of locks and constipation.

-

If necessary, forged decorative elements are installed on the wicket.

The steps for making a wicket from a profile pipe can be viewed in the following video:

It can be interesting ! In the article on the following link read about the fence of corrugated board.

Conclusion

The fence made of brick and profiled sheet is one of the most durable metal fences and allows you to create original combined structures of any size and shape. Due to the wide range of colors, a fence made of corrugated flooring with brick pillars can become an original design project that allows you to combine the entire suburban area into a single harmonious composition.

Rate this article, we tried for you