The device of a draft floor in a frame house depends on the type of foundation on which it stands. And the type of the base even of such a light structure depends on the nature of the soil. And there are no restrictions on the materials - it can be concrete floors on the ground, and wooden floors on logs. But the first option, if used, is only on a slab or strip foundation. Although for a strip foundation, a rough floor on lags is more common. And given the fact that the frame house is usually put on a screw or column foundation (if geological features of the site allow), the draft wooden floor is most common.

General conditions

B In principle, there are two types of wooden subfloor of the first floor of a frame house:

-

an air-supported structure on a strip or pile (screw) foundation;

-

trellis construction on a slab or concrete screed.

In the first case, the horizontal level should already be observed at the level of the base, grillage or strapping, in the second - when pouring the base.

In the presence of a subfloor in a strip shallow-buried foundation in the bearing walls of the base around the perimeter and inside it, air vents should be laid for ventilation.

Note . Products should also be left when arranging the fence (cap) of the pile foundation.

In order to prevent the tree from rotting when in contact with a concrete or metal surface, the places of support of the supporting beams of the ceiling on the foundation are insulated with the help of roll bitumen waterproofing.

All wooden elements must be treated with antiseptics, used metal fasteners and fasteners must have anti-corrosion coating.

Structure of the subfloor

The structure of the floor structure in a frame house does not differ from the walls.

There are also power elements responsible for the reliability and durability of the structure - lags and jumpers. They are also attached to the supporting base - the foundation. And in the context of this is the same sandwich - thin-skinned frame of the frame, inside of which is a heater. And so that the insulation and wood do not get wet from condensate and atmospheric moisture, they are protected with special films and membranes.

Arrange the subfloor in a frame house in two stages.

Features of the first floor subfloor. First Stage

At the first stage, immediately after the completion of the foundation construction, a floor supporting structure is installed - logs and crossmembers.

And here there are various options for mounting them:

-

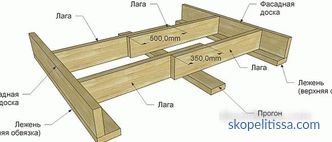

Lags are fastened on top of the beam of a pile foundation or a strip foundation on nails. At first, along the two opposite walls, a facade (strapping) board for log is attached to a timber or plank. And then the lags themselves are placed between them. If necessary, they are increased overlap, which should be based on one of the inner bearing walls of the strip foundation or the internal beam of the grillage (girder).

On our site you can see the most popular projects frame houses from construction companies presented at the exhibition "Low-Rise Country".

The rigidity of the structure is provided by additional spacers, the length of which must correspond to the lag step (minus their thickness). How it does Larry Hon can be seen in the video below:

-

The lags are attached on top of the trim or beam, fixing them directly to the uprights of the walls on nails and brackets. In this case, the lag layout completely coincides with the pitch of the racks, and this is not always “convenient”.

-

Lags are fixed in a bar strapping, for which make special slots.

-

The lags are attached to the trimming bar on the inside using special brackets.

There is no single opinion about the lagging step.

More "economical" option - 600 mm. And if we talk about axial distance, then taking into account the thickness of the lag - 625 mm. But some experts recommend a step - 400 mm. And although with the wadding of mineral wool, the mats will have to be cut, the design of the subfloor will be much stronger.

Important! In places where heavy equipment is installed (stove, fireplace, floor-standing boiler with a boiler), the layout (pitch) is further reduced.

The principle of lag reduction in places where heavy objects are installed is used not only in frame houses.For example, the same advice can be heard in the next video, although here it is told about the device of the subfloor of a timber house. As you can see, in practice there are no fundamental differences - this is the same wooden floor of the first floor:

On our website you can find contacts of construction companies that offer renovation services and rebuilding homes. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Installation of the subfloor. The second stage

The second stage of the construction of the subfloor is started after the walls are standing and the roof is mounted. Although the frame houses are fast-built, precipitation can "happen" at any time, and mineral wool should be laid, provided that it does not get wet from the rain.

There are three ways to make a floor in a frame house (or rather its lower part):

-

The base is hemmed with a bottom . It is made of board, moisture resistant plywood or OSB. Since decorative qualities are not needed for this, the board can be taken uncut, but it is necessary to remove the wane (bark) and treat it with an antiseptic. All the load that will fall on this foundation is the weight of mineral wool. Therefore, it is sufficient if the board is 20 mm thick, and plywood or OSB is 10-15 mm. The disadvantage of the method is the attachment of the base from the side of the hemlock, and this is possible only with sufficient clearance to the ground.

-

Binder the base is carried out on the "cranial" bar . So called a small cross-section bar (usually 50x50 mm), which is attached to the logs on the side wallpaper at the very bottom. On these bars lay the boards of the basis or the cut plywood sheets (OSB plates). Moreover, their attachment to the cranial bar spend purely "symbolic." The advantage of the method is that the installation is carried out from above, so there is no limit on the clearance between the ceiling and the ground. The disadvantage is that the logs should be at least 200 mm high (250 mm is even better) in order to compensate for the loss of useful space for floor insulation. You can also note as a disadvantage additional purchase of the bar.

-

Draft Pie the floors of the frame house are mounted on top of the lag . This method is used if the base is low and there is practically no subfield. In fact, it is necessary perpendicular to the lags of the main subfloor to lay additional lags. In this case, the base of the subfloor is attached to the main lags, and additional lags are mounted on it - they serve to fix the finishing floor covering.

After the base is mounted, a waterproofing membrane and insulation are placed between the lag (basic or for the third method additional).

It may be interesting! In the article on the following link read about how to warm the floor in a private house.

Pie of the first floor subfloor

The correct arrangement of the layers of the wooden floor of the first floor looks like this:

-

base;

-

diffusion waterproofing membrane;

-

insulation between the lag;

-

vapor barrier film;

-

directly to the sub floor itself, as the base of the finishing floor covering.

Note . If a floorboard is used as a topcoat, it is mounted on the logs above the vapor barrier.

Such an arrangement protects the insulation from the penetration of water vapor with warm air from the side of the room, and does not prevent their weathering to the outside - in the underground.

Mineral wool, ecowool, plain or extruded polystyrene foam is chosen for the frame of the skeleton. Preference is given to mineral wool due to its incombustibility. But if you need to make the floor warmer with the same thickness of insulation, then use a combination of polystyrene foam and mineral wool. Below put foam plastic with a thickness of 10 cm, and on top of mineral wool.

It might be interesting! In the article on the following link read about how to paint a wooden floor in a house.

Draft floor of the second floor

The construction of a rough floor in a frame house on the second or attic floor is different from the basement floor.

There is a vapor barrier in a different way here and there must also be elastic gaskets to compensate for the impact and structural noise. In addition, only mineral wool is used as an insulating layer. Moreover, this is explained not only by its incombustibility, but also by its ability to absorb airborne noise, which the foam plastic does not have. That is, it acts not as heat insulation, but as noise insulation. Therefore, its thickness will be less (although for this case it is better to choose mats for special acoustic wool).

Note is important for the floors and floors of the second floor of a frame house. Airborne noise includes any waves in the acoustic range - it is speech, music, operating a TV or a stereo system. Shock noise is walking on the top floor, sounds from falling objects or moving furniture. Structural noise spreads over the structural elements of the operating equipment (ventilation, air conditioning, pumps, water supply and heating systems).

Recommended from the point of view of sound insulation the sequence of arrangement of layers of the second floor (from top to bottom):

-

finishing coating laminate - with foam polyethylene substrate);

-

plywood or OSB board;

-

rubber or cork substrate glued on top of chipboard (or plywood);

-

rubber or cork pads on floor beams ;

-

mineral wool between the beams;

-

vapor barrier ;

-

sheathing ;

-

ceiling lining (drywall, wag Onka or panel);

A few more useful nuances on the design of the subfloor in the following video:

It can be interesting! In the article on the following link read about waterproofing the floor in a wooden house.

Conclusion

The draft floor must be reliable and durable - its main elements are part of the supporting structure of the frame house. In addition, it should have good heat and sound insulation properties - it is compliance with this part of the conditions that is responsible for comfort. Therefore, everything here should be done on the basis of the project, the calculation of which should be carried out taking into account regulatory requirements and climatic conditions of the region. And this is a job for professionals.

Rate this article, we tried for you