A bath has existed in different cultures since time immemorial. Always and everywhere it was considered a place of not only rest and purification, but also healing. In Russian culture, the baths are characterized by a cozy, homely atmosphere - a rare owner will deny himself the pleasure of having such a useful thing at his own disposal.

If a traditional log house or brick building does not fit into the budget, modern construction technologies will come to the rescue. The frame bath is a practical option, not inferior in performance to its predecessors. Such an unusual departure from the construction canons has only recently caused general mistrust; In recent years, interest in frame buildings has shown strong growth.

Let's look at this issue in more detail, including the pros and cons of the frame bath, as well as why they are gaining such demand today.

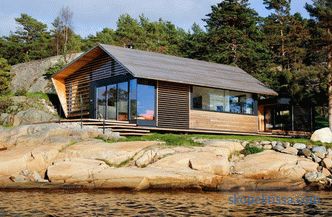

The frame bath can be a decoration of the site

Pros and cons of the frame bath

Frame baths are of great interest due to the undoubted advantages over other structures:

-

Efficiency. The cost of 1 m 2 is lower due to lower labor costs and the cost of materials (starting from 5 thousand rubles).

-

Construction Period. It takes 3 times less time to build a frame bath than on a bar from a bar (especially from a brick); installation (along with finishing and insulation) takes 20-40 days (depending on the complexity of the work) and can take place at any time of the year.

-

Operation. The bath can be used as intended immediately after construction.

-

Thermal insulation. The bath from the frame is quickly melted and retains heat well at any time of the year.

-

Reliability. The service life of a building erected without technological blunders is from 10 to 20 years.

-

Ecology. The bath maintains a comfortable microclimate and is safe for health.

The frame design pleases owners in any weather

To the features of frame projects baths include:

-

Lightweight foundation. The finished structure is lightweight because it requires 1.5-2 times less wood than buildings made of timber or logs. This allows the use of a columnar or shallow foundation.

-

Insulation. Properly selected insulation contributes to energy saving; the frame bath keeps heat not worse than a bar-shaped one.

-

Architecture. Features of the technology allow you to create a variety of planning and facade solutions (with a veranda, a mansard).

-

Accommodation. The frame bath can be put on the problem area (with a high level of groundwater in a flooded place).

The negative sides include:

-

Insulation and finishing costs. Constitute a significant part of the cost of construction, but you can not save on them. Cheap mineral wool will not provide high-quality insulation, the foam is fire hazardous.

-

Shrinkage. The shrinking process can last up to 2 years (if natural wood was used for construction); at the same time there is a high probability of damage to the finish (plaster or decorative panels). Wood drying chamber has almost imperceptible shrinkage, but its use will cost more.

The photo of the frame bath project is a modern interpretation of the traditional construction

Construction of baths from the frame

The cozy building will appear on the site in a few weeks, unlike the brick construction, the construction of which will take a year. The ability to provide a family with a practical steam room, without spending a lot of time and money, looks very attractive. The construction stages of a frame bath are determined by the technology:

Project

The success of the future construction depends entirely on the thoroughness of planning and design, which is especially important on a small plot of land. The use of a finished project (possibly with changes) can significantly speed up the process.

The project determines the location of the steam room, shower, rest rooms; the roof structure and the installation location of the furnace are planned. Considerable attention is paid to engineering communications - the safe installation of electrical cable, the connection of water supply and sewage pipes. In the preparation of the project take into account:

-

Location. The sides of the world and the distance to the borders of the site are taken into account. Bath oriented so that the rest room looked at the inner territory, and not rested against the fence of neighbors.

Typical design of a frame bath

On our site you can read the most popular projects of frame baths from construction companies represented at the exhibition of houses "Low-Rise Country".

-

Architectures and . A bath may contain additional elements - a wooden staircase and a carport at the entrance, a veranda or an attic.

-

Windows. Usually one window is designed in the rest room (light source) and along a small window in the washing room and steam room (extra ventilation). Sometimes add a window on the gable of the roof.

-

Convenience. A gable roof will allow you to organize a small attic, on which it is convenient to store bath brooms. Underfloor heating must also be provided at the design stage.

Foundation

The construction of a light-weight frame bath does not require a complex foundation, including digging a pit; This affects the budget in the most pleasant way. For reliable soils, the best option is a strip or column foundation, the depth of which is influenced by the proximity of groundwater, the type and level of soil freezing.

If the site is located in a zone of regular flooding (spring floods), you can insure and choose a pile-screw foundation. Pre-made trial screwing, which determines the depth of the pile. If it turns out that the piles are much longer than the calculated ones (not 3, but 5-7 meters), the foundation will become indecently expensive, and you will have to think about another option.

Frame bath photo - a classic building on a column base

The simplest (and fastest) scheme is considered columnar foundation of asbestos-cement pipes. Such a foundation serves as an additional protection of walls against dampness and is laid in several stages:

-

Wells are drilled along the marked contour.

-

Asbestos-cement pipes are inserted into the wells. The free space around the pipes is filled with coarse sand and carefully compacted.

-

Concrete is poured inside the pipes, an iron plate is placed on top of each.

If a strip or slab foundation is selected for the construction of a bath, before it is poured in, it is necessary to make engineering utilities inputs (water supply, sewerage, electricity).

About the process of designing a bath from the frame to the video:

On our site you can find contacts of construction companies that offer the service of building frame baths. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Frame

Before building a frame bath, choose the material for the frame; softwood is most commonly used. Installation of the frame, which is the supporting element of the bath, includes:

-

Installation of the bottom trim. For it use a bar or the boards which are previously processed by an antiseptic; lags for the future floor are mounted on top. The whole construction is waterproofed with roofing material and mastic.

-

Installation of frame walls. Passes by successively adding vertical and horizontal elements, to which the sheathing is then fastened (OSB boards, clapboard). The frame is taken into account in advance openings under the windows and doors.

Wooden paneling of the frame bath

Floor

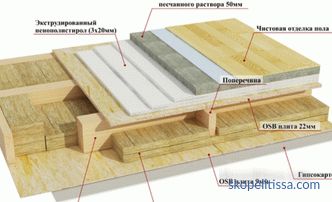

The floor in the bath has a different design in the dressing room and the washing part. In the dressing room, the floor is a multi-layered cake, which includes a draft floor, waterproofed roofing material, a layer of insulation (also waterproofed) and finishing floor. The washing feature is the pouring floor for which it is necessary to properly equip the drain system. The problem is solved in different ways:

-

Construct an internal, isolated foundation with a concrete screed (with a slope and water out of the bath) and double waterproofing.

-

The draft floor (with a slope to the outer wall) remains common, the roofing material rises 30-40 cm along the walls and is covered with a covering (clapboard).

In both cases, the floor is lined with an antiseptic-treated board. Wooden floorboards need to be replaced after some time (4-5 years); therefore, plastic analogues are sometimes used instead.

Sometimes a wooden chute is arranged in the steam room, dividing the floor into 2 parts. The floorboards converge to the gutter, allowing the water to drain quickly and out. Thanks to this design, the floor dries quickly and does not rot.

Multi-layer floor device in the frame bath

Roof

Trussing elements are assembled on the ground and take turns climbing up. If the bath is small, soft tile (ondulin) is optimally suited as a roof. If the structure (and foundation) is more serious, it is not prohibited to use metal tile.After the completion of roofing works, windows and doors are installed in the provided openings.

It may be interesting! In the article on the following link read about the project of a house with a bath.

Warming and finishing

The frame bath needs careful warming and finishing.

-

Wall cladding. Outside walls are sheathed with a block house, clapboard or siding, which adds stiffness to the structure. Under the skin lay a layer of hydro-and thermal insulation. In addition, the foil is placed in the steam room.

-

Draft ceiling. Mounted from OSB sheets or boards, insulated with 2-3 layers of fireproof insulation.

-

Interior trim. The inner side is covered with insulation and a vapor-protective film. Walls are lined with clapboard, decorative panels, plasterboard or other suitable material; The steam room is preferably lined with linden clapboard.

Metal furnace before and after modification

Furnace

In a traditional Russian bath, the air retains high humidity (unlike a sauna, the dry air of which does not suit many people). The most important part of any bath is the stove, the design of which determines the rate of steam heating and the properties of the steam. Furnaces of several types are common:

-

Stone. Talkohlorite is used for construction (in the form of tiles), which affects the price of this design.

-

Brick. The firebox is laid out with fireclay bricks. Such a furnace is cheaper than stone; steam quality is somewhat lower.

-

Metallic. Inexpensive and most common option, quick to assemble. The metal furnace heats the steam room faster than other structures, but it is rather difficult to maintain the desired temperature and steam quality. So that the temperature in the steam room is evenly distributed, the oven is covered with bricks.

About the details of the construction of the frame bath in the video:

To protect the frame construction from fire, the furnace and pipe are mounted in compliance with fire safety regulations:

-

Wooden surfaces within a radius of 1 m around the furnace are insulated with basalt wool or heat-insulating fabric.

-

Insulation of pipes and ceilings in the attic is carried out with non-combustible materials.

-

A steel sheet is laid in front of the stone (brick) furnace's stove door. If the furnace is metallic, a foundation of concrete or bricks is arranged under it.

Ventilation is thought out at the planning stage

This can be interesting! In the article on the following link read about the bath.

Ventilation

The choice of the ventilation system depends on whether the furnace is located in the steam room or adjacent room (which is more often designed because it saves heat). In most baths mounted mixed (forced-air and exhaust) ventilation system. For this purpose, the following are envisaged:

-

Supply (inlet) holes, through which fresh air enters the steam room; they can be equipped with a fan.

-

Exhaust (outlet) openings that release heated air to the street.

Lighting

The windows in the bath are traditionally small - this helps to retain heat. To increase the amount of natural light in the bath without a loft an additional window can be installed on the roof. For the organization of artificial lighting choose sealed lamps, protected by matte fog lampshades.

About the review of the frame bath in the video:

Turnkey frame bath

Construction companies offer frame bath projects of various sizes and designs that contain all the necessary elements - a waiting room, a washing room and a steam room. The package may include a veranda, terrace, balcony or bay window. When ordering a turnkey frame bath, you can be sure that:

-

The project will be adapted to the conditions of a particular land plot: if necessary, a geological survey will be conducted.

-

The cost of construction includes the delivery and unloading of materials.

-

The foundation will be built taking into account the characteristics of the soil.

-

The construction will use environmentally friendly building materials.

-

The design will reliably insulate and protect against moisture.

-

The works will be completed within the agreed time (under the contract).

Project of the frame house of the bath - the attic floor of the bath is suitable for arranging the rest room

The result of the turnkey order will be a bath, fully ready for operation. Additional bonuses that exist in many companies include:

-

Hire purchase. Allows you to plan family expenses.

-

Direct cooperation with lumber suppliers.This allows you to keep prices at an affordable level.

-

Gift. When ordering a turnkey, some work (installation of the furnace, wiring electricians) are performed free of charge.

It might be interesting! In the article on the following link read about the 6x4 bath.

Conclusion

The frame bath is an excellent option for those who want to equip a personal plot qualitatively, quickly and inexpensively. Contrary to the well-known joke (choose any two) a professional approach, many years of experience and high-quality materials allow you to build a bathhouse with a thoughtful design and excellent performance characteristics.