The history of wooden housing is estimated in the millennia. Warm, breathable and light wood has always been valued for its qualities. Despite the emergence of new materials and technologies, it is traditionally considered the best for the construction of residential buildings. Felling spread out of horizontal crowns, interconnected cut down or sawn locks. The main task during construction is to ensure a tight fit of all elements. Cold corners are not such a rare problem of wooden buildings. Non-insulated gaps serve as a direct channel for heat loss. The joint of the corner bars should provide isolation of the premises from the environment. This type of construction was called the "warm corner". It is performed in several ways. Assembly assembly is carried out with the help of locks of various shapes, with a small number of additional fastening parts.

Timber in construction

A log building is erected from a profiled or glued timber. The first type is made of solid wood without destroying the structure and use of adhesives. The outer side is treated as a flat or convex surface, with or without a facet. Internal - usually flat, under the finish. The bearing faces have a thorn-groove system, thanks to which the elements are firmly joined. Profiled material is easy to use, the section has standard dimensions. When building wooden beams do not need to be customized.

Glued laminated timber, unlike solid profiled, consists of glued thin lamellae. To perform the joints in the factory, select the grooves and drill holes. On the construction site, it remains only to assemble ready-made links, as a constructor.

Houses made of wooden profiles have advantages over brick or concrete:

- Quickly erected, do not require "wet" work on mixing the mortar or concrete.

- Light, do not need powerful deep-seated foundations, a sufficiently reinforced concrete base of shallow foundation or a "floating" slab.

- Warm, the thermal conductivity of wood is 0.09 W / m ° s, which is comparable with the characteristics of basalt wool.

- Beautifully folded wooden buildings harmoniously look at the background of greenery, nature, do not require additional finishing with siding, decorative panels, and plaster.

- The favorable microclimate in the room is ensured by the high vapor permeability of the wood, in such a house the optimum humidity is maintained.

- A quality log house is durable, stable and durable, its service life is not inferior to stone structures.

A warm corner is a section of the most technologically complex components. Due to the peculiarities of wood, shrink, swell and warp joints at the intersection of elements are subject to multidirectional stresses and the formation of gaps. Proper mating is a guarantee that over time there will be no through-slots, from where the wind will blow and dampness will penetrate. The classification, design types and recommendations for calculating the size of corner joints are provided by GOST 30974-2002.

On our website you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Types of joints

To know what a warm corner is, every builder should build a house from a bar. Design documentation contains the necessary information about the designs and sizes of corner joints. They are made in the form of grooves and protrusions of various shapes. Two, three or four elements are connected to each other and form a solid basis for laying the next crown.

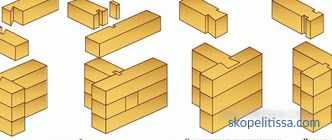

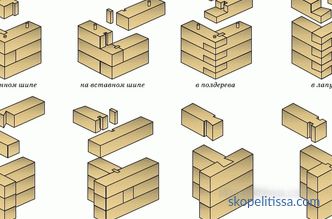

Constructive solution of the node can be in the form:

- connection without residue, when the elements do not intersect the border of the joint; out;

- butt-end - the elements are adjacent and fastened with brackets, dowels, overlays;

- T-shaped - a pairing wall and pier.

The grooves in the wooden profiles are selected with the help of a chainsaw, jigsaw, and a manual cup-cutting machine.

The requirements for connecting the links are:

- Ease of execution.

- Durability.

- Minimum heat loss.

In the construction of wooden houses, the following types of corner joints are used:

- in the "cup";

- in the "paw";

- on rectangular keys;

- on dovetail dowels;

- with root spike;

- in oblo — with one, two, or four-sided keyways;

- open or closed "pan" - a trapezoid symmetrical spike;

- open or blind "half-crotch - a rectangular spike.

The required insulation of the joint is achieved not only by the design of the joint, but also by using heat insulators:

- elastomeric and polymeric tape materials;

- tow;

- moss;

- jute;

- flax fiber;

- foam or silicone sealants.

They are placed in the recesses of the profiled bars, grooves of the locks, the seams between the crowns.

Wood for building a house should be well dried, have a moisture content of not more than 20%. This is the main condition for the strength and reliability of the design. After preparation of the elements they are treated with an antiseptic, so that all the cuts receive a protective coating.

You can see how the beam is connected to a warm corner in this video:

It might be interesting! In the article on the following link read about grinding timber.

Butt-joint

The simplest design of the assembly. The butt joint is carried out with the help of metal studded plates, corners. They are fastened with staples or nails. The end of the profile is carefully leveled to ensure a snug fit.

The connection outside is insulated so that wind and cold do not directly penetrate the gap. To this end, a heat insulator is laid along the end of the adjacent timber.

Such a conjugation of links is used if the insulation of external walls and cladding is intended.

First, be sure to caulk the gaps, as the profile wood is prone to drying out. Warming is carried out on the surface of the wall, on top of it is laid the hydro-windproof membrane, and the exterior finish is mounted.

Butt-butt-joint is quick to perform, but for a high-quality warm corner in a house from a bar it is not suitable. Too many additional operations need to be done to ensure its thermal insulation. This method is used for the construction of outbuildings and other non-critical structures.

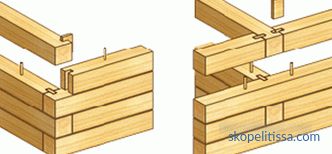

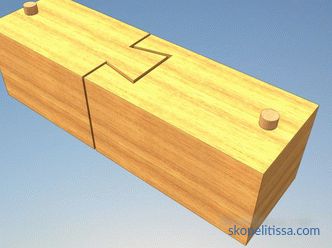

Butt with key

This is a reinforced butt joint of two elements, in the end and in the side of which choose holes according to the shape of a key, 0.2-0.3 in depth from the thickness of the beam. Fasteners are made of hard wood - ash, oak, aspen.

A key can have a rectangular cross section or dovetail shape with extensions to the edges.

When fastened with a rectangular element, the strength of the structure in one direction is achieved. The “Swallow Tail” better fixes the parallel bars, but requires accuracy when selecting the grooves and preparing the key.

With a root spike

The joint was called the “warm corner”, the timber in such a node mount is less susceptible to displacement. Violation of the tree structure is minimal here, and the spike on the inner surface of the mate serves as protection against the penetration of cold air.

Timber is pre-prepared:

- At one end, a protrusion of a length equal to 0.2 of the bar thickness is cut out, rectangular or with an extension to the edge ("half-sheet").

- In the second part, select a groove with a small gap for free entry of the root spike.

- A thin layer of insulation is placed in the groove, for example, a linen-jute cloth.

Insert the spike into the recess, fasten the knot with the lower crown with a long dowel.

A variation of a node with a root thorn is a dovetail connection, or frying pan ". Most often used for T-shaped joints of walls and partitions. The spike and groove are trapezoidal in shape. The protrusion is cut in the middle of the end of the beam. For marking use special templates of suitable size.

A log cabin with laying of crowns in a "warm corner" sits evenly, the bars do not diverge when the humidity in the joints fluctuates.

It can be interesting! In the article on the following link read about paint to imitate a bar inside and outside the room.

Connection "in the paw"

Fastening is used for splicing the corner links and making T-shaped interfaces of the walls. At the ends, horizontal protrusions are cut out in the form of a complex trapezoidal prism - the “paw”. Joints in the node are located in 4 inclined planes.

This type of mating reliably holds the corner links together and prevents their divergence both inwards and outwards. Heat insulation of the joint is performed by laying insulators.

Connections with the remainder

The colorful view of the log house, which is folded with the beam at the corners, compensates for the costs of overspending the material. Connections with the remainder are made in various ways:

- In the lower rim, a groove is chosen for laying the upper half-shaped lumber. This is a one-sided node in the "Oblo" or "half-tree."

- A double-sided lock involves cutting through the recesses below and above. In every detail there is already a nest for the installation of the next crown.

- The four-sided connection in the "Oblo" differs from the others in the selection of grooves on all surfaces of the beam. This form gives the stability of the structure even without the use of pins.

heights.

Connecting a beam to a warm corner - advantages and disadvantages

The main advantage of this method of cutting a house is the absence of blown and freezing cracks. No additional insulation of the facade and further exterior wall decoration.

When assembling a house, the spikes and grooves of the connecting nodes are performed manually. This is perhaps the only drawback of this type of construction.

Ready-made sets of laminated veneer lumber do not have this minus. All elements are pre-processed for convenient installation and assembly of components. The crowns are marked according to the working drawings. On the construction site, the house is built in a few days, using the instruction with the developed scheme.

That might be interesting! In the article next link read about profiled timber.

Total

Laying a beam in a "warm corner" requires considerable effort, highly skilled craftsmen and material costs. But it quickly pays off savings on heating housing.