The variety of roofing materials makes it possible to choose the right option, which is suitable for the roof of a house in many ways. But this article will talk about the device of the roll roofing. Let us tell you what materials for this can be used, about their minuses and advantages, about the technologies of their laying on the roof with the designation of the important nuances of the construction process.

Types of roll roofing materials

The time when roofing felt is gone and roofing were the only roll materials that covered the roofs of buildings and structures. The cardboard base and not the highest quality bitumen did not allow to extend the life of such roofs more than 5-7 years. The material quickly cracked under the action of sunlight and temperature drops, atmospheric precipitation added negatives, and the roof quickly broke down.

Scientific and technical progress has done its job, therefore roll roofing materials with higher technical and operational characteristics appeared on the market. Hence, their longer service life is up to 30 years. It should be noted that modern roll roofing is a universal material. It can be used not only for roofing, but also for waterproofing various building structures. For example, the foundation.

Ruberoid and tar only still produce some companies and put on the market as the cheapest option. And the consumer of these materials are still found. But the bulk of sales are in roll products, which are based on more durable and wear-resistant materials, namely fiberglass, fiberglass and polyester. The latter is the most durable and reliable, but the price of such a roofing is the highest.

As for the binder, today it is used two types: oxidized bitumen and bitumen-polymer mixtures . The latter are better in all respects, that is, they are more flexible, they easily tolerate serious changes in temperature and humidity, and withstand rather large mechanical loads. Different substances are used as polymeric additives, but most manufacturers prefer styrene butadiene styrene as the best representative of its class.

And another ingredient that is an integral part of the roll roofing material. This is a stone dressing. Its purpose is to protect the bituminous binder from the negative effects of sunlight. Usually it is applied only on the front side of the rolls. Today, manufacturers offer roll roofing with different dressings. Here we have in mind the size of the granules used: large, medium, fine-grained, dust-like and scaly.

It should be noted that manufacturers today offer another variety, which is called baseless. This material is made of pure bitumen-polymer mixture, which is rolled into rolls.

Generations of coil material

The evolution of the development of a roll roof is quite interesting. As in any process, the development went from simpler to more complex and reliable.

-

Ruberoid based on cardboard.

-

The deposited roofing material . It differs from the usual one in that the lower bitumen layer is thicker. It is heated to make it sticky.

-

Glass Reinforcement . As mentioned above, it is based on fiberglass, fiberglass or polyester. Installation of a roll roofing of this type is carried out either in a hot way, that is, using fusing technology, or cold - gluing with bitumen mastic or using mechanical fasteners.

-

Membranes . This is the most modern version of roll roofing. It is based on fiberglass. At the same time the material itself is self-adhesive. That is, the lower adhesive layer is closed with a polymer film, which is removed before installation.

Now for the labeling. It should be noted that the market today offers two main types of this material: roofing with the marking "K" and lining with the marking "P". The latter is more often called underlay carpet or under-roofing.

To begin with, the lining version is produced without stone powder. Its purpose is to align the plane of the roof or the crate on which the roofing material will be laid, and also to hide their defects.

Technology for laying a roll roof and how to fix it

So, we proceed directly to the topic of the article, namely to the roofing of roll materials. Let's start with the fact that much will depend on the angle of the roof of the house. This affects the number of stacked layers.And the smaller the angle, the more layers will have to be laid:

-

If the angle of inclination exceeds 15% , then 2 layers will suffice;

-

If the slope is 5-15% , then it is better to lay 3 layers;

-

If less than 5% , then four.

Please note that it is not recommended to lay rolled roofing materials on roofs with a slope of more than 25%.

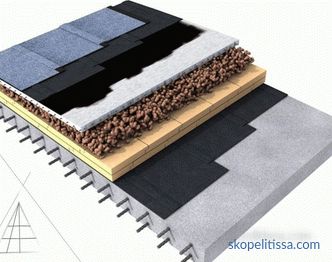

The technology of laying roll roofing is based on the installation of several layers of different building materials. And the complexity, as well as the cost, will depend on whether the roof of the house is insulated. Let's consider this option - with warming.

Roll roofing on a flat roof

What is a flat roof? This design of reinforced concrete slabs or poured monolithic slab with a reinforcing frame inside. In any case, it is a horizontal element of the building, which is poured over with a coupler. It is the latter that creates a minimum bias in the range of 1-5%.

Begin the installation of the roofing material by examining the flat concrete structure for the detection of defects and flaws. If they are found, they should be sealed, for example, with repair cement-sand mortar (proportion: 1: 1).

On our site you can familiarize yourself with the most construction sites in the Moscow region country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

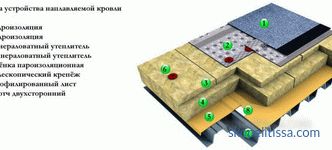

Further, the sequence of operations performed is as follows:

-

The renovated roof is cleaned from debris and dust.

-

Cover cleaned floor slabs with a bitumen primer or deep penetration primer. These are liquid materials that are applied to the surface by roller.

-

Covering the vapor barrier membrane. Its purpose is not to let in the insulating layer of moist air vapor that rise from the interior of the building.

-

Spend installation of insulation . Optimal for flat roofs - polystyrene plates, where the best representative is "Penoplex". It is glued with a special adhesive, additionally fastened with mushroom-shaped screws made of plastic. Penoplex plates are joined together with a groove-thorn joint system, so that the heat-insulating layer on the roof will be free of gaps and cracks.

-

They put waterproofing film , which is laid out in strips with overlapping edges in the range of 10-15 cm.

-

Fill on top of the heat-insulating cake a concrete screed , which will determine the angle of inclination of the flat roof.

-

When the screed layer dries, go to spreading the lining carpet . The strips are laid with offset and padding of the edges 10-15 cm. The fastening of the under-roofing material is carried out with the help of bitumen mastic, coating it along the perimeter of the strips.

-

From above they put roofing material .

Today the most common method , he is also the most reliable - built-up roof. How to do it. First, it requires a propane tank, a hose, and a gas burner. As well as two additional tools: a poker and a metal roller, the latter can be replaced with a wide trowel. Secondly, for the installation process, two workers are required: one will heat the roofing material and roll it with a poker, the other will level the rolls by rolling the roller over the entire surface.

The video shows how the overlaying roof should be laid on a flat roof:

Often, hangars and storage rooms are constructed in a frame-like manner with profiled sheeting. And such structures are sometimes erected with a flat roof or with a tilt angle within 15%. And if there is a need to conduct insulation of this type of building, the process itself is carried out from the inside or outside. The second option implies the presence of a roll roof.

The technology of a roll roofing device by sheeting is practically no different from the previous version. It just does not pour concrete screed. That is, the profiled material is covered with vapor barrier, over which insulation is laid. Waterproofing is spread from above, and already above the roofing carpet and the soft roof itself.

It should be noted that the installation of bitumen roofing on the insulating layer is not the most successful technology. But in the facilities of this type there is no other way out. Their roofs can not be overloaded with heavy materials, which include the screed solution.

So, we have considered a soft roof with mounting technology on a flat roof. We proceed to the pitched structures.

On our website you can find contacts of construction companies that offer services design and repair of the roof . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Roll roofing on a pitched roof

To begin with, the pitched roofing structure is based on a truss system. Warm such a roof in one way - laying the insulating material between the rafter legs. Bottom from the inside of the attic or attic close the insulation waterproofing, outside the vapor barrier. Both materials are attached to the rafters and stacked across them from bottom to top with overlapping edges.

As for the soft roll roofing, it is placed only on a continuous crate. The latter is a layered board or plywood sheets, or OSB boards.

The process of laying a soft bitumen roofing itself differs little from installation on a flat roof. Just the lining carpet is laid across the truss legs, the roofing material itself is along, taking into account the overlapping of the stacked rolls. In this case, the under-roofing material is attached to the crate with roofing nails. But the roof itself is often a method of welding, as shown in the photo below.

Cold-mount technology

I would like to pay a little attention to cold technology installation of roll roofing material. It is clear that this method received this name only because it does not use open fire. But for this, you will have to purchase a certain amount of bitumen mastic, because it is this material that acts as an adhesive between the lining and the roof covering.

What are the nuances of this technology:

-

Optimally - before starting the installation process rolls of soft roof spread out on the roof so that they align. Usually in this form, the material is left for a day.

-

The opened roll is laid at the place of installation . Align the edges, if necessary, cut off the excess protruding beyond the roof structure.

-

Then they turn from two sides to the middle. That is, there should be two rolls.

-

Bitumen mastic is applied under one of the rolls . Use a spatula, paintbrush or roller.

-

Roll out a roll , rolling on its front side with a clean paint roller.

-

Similarly, the second part is being laid.

It should be noted that membrane roll roofing materials are attached to the base of the roof or with the help of nails, or with the help of a special adhesive composition. The latter option is more expensive, but more reliable. At the same time, they try to seal the edges of the laid strips. This can be done with the same glue or use welding technology, using special equipment.

The video shows how to weld roofing membranes on the roof:

It might be interesting! In the article on The following link read about the top 10 stairs in the Art Nouveau style: complex in a simple .

Conclusion on the topic

So, we tried to give complete information on the soft roof (its device and installation technology). As practice shows, more and more private developers give their preference to this particular roofing structure. Especially those who are constrained financially. After all, of all the roofing coatings roll version is the cheapest.